- OBJECTIVE:

- To lay down the procedure for operation of Isolator. Make: Bectochem.

- SCOPE:

- This SOP is applicable for the procedure for operation of Isolator in warehouse department at {Company Name} {Location}.

- RESPONSIBILITY:

- WH Executive/Designee – is responsible for ensuring compliance with the SOP.

- Head Warehouse – is responsible for compliance of the SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

- PRE-CHECKS:

- Check the cleanliness of the area and the equipment.

- Close all the doors and ensure the isolator leakages if any.

- Ensure the Isolator Utilities Are in Open Condition.

- Ensure the catch pot is connected to the isolator and it should be open.

- Ensure all hand gloves are in good condition before starting dispensing/sampling operation.

- Check the integrity of all the gloves before proceeding.

- Record the observation in Format.

- Check visually the gloves full inflation during the switch “ON” mode of Isolator.If any of the gloves do not get inflated due to torn, damage or pinholes, stop the isolator and replace the gloves.

- Check the new gloves fixed during the switch “ON” mode of Isolator and proceed.

Note: Replace the gloves if found damaged or every 3 years.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/procedure-for-operation-of-dispensing-sampling-isolator/

- OPERATION:

- Switch on the main power supply by turning the Control button to ON position.

- Start the Isolator by pressing the POWER RESET button then press the FAN START button (green colour) on the control panel of the isolator.

- Ensure the Isolator “HEALTHY CONDITION “indication By Observing the Green colour light glow on the front panel of the isolator.

- In case of power failure, the system will shut down and stops all control functions.

- When the Power is re-established press POWER RESET BUTTON on the local control panel, the system will revert to Standby Mode.

- Then press the FAN START green color button to turn the system to RUN Mode.

- Check and ensure the magnehelic gauge readings are within the limit.

- If not inform to the maintenance department for rectification. Magnehelic Gauge Limits in Pascals:

| S.No. | Main Chamber | Drum Loading | Pass Box (Exhaust) |

| 1 | -80 to -120 | -80 to -120 | -80 to -120 |

- Containment Breach modes:

- If any leakages occur while running the fan the isolator will turn to containment breach mode will be indicated by glowing the red colour lamp on the panel and it will give audio alarm.

- The isolator healthy condition (green lamp) will switch off and containment breach mode will glow in yellow colour lamp.

- In containment breach mode the negative pressure of the isolator increases to alarm level.

- The system will remain in this containment breach mode until the cause of pressure loss has been rectified.

- In this case switch off the isolator and inform the maintenance department for rectification through work order.

- Containment breach mode will automatically reset when the cause of pressure is re-established and the system will turn to RUN mode.

- Drum Loading:

- Carry the trolley of the mother drum to load the child drum.

- Place the shell of the Mother Drum and secure the clamps and carry the mother drum near to the workplace.

- Remove the lid of the mother drum and place it aside.Clamp the mother drum on the tilting trolley.

- Put the outer/inner seal door button in outer position then deflate the door by pressing outer seal deflate button on the LOP Pannel-2 and remove the outer lid.

- Press continuously ENERGISE button and press the DRUM RAISE button to raise the drum up to the outer seal door.

- The mother drum is inserted into the inflatable gasket by operating the SLIDE IN button from the Drum Loading Panel.Keep the outer/inner button in inner position, then press the ‘inner seal deflated button’, then remove the inner seal of door immediately so that the outer seal of the sealing system inflated and the system gets airtight.

- Dispensing/Sampling chemist should stand in front of loading chamber.

- Remove the inner lid of the sealing system and hung inside by operating through the Glove ports of the loading Chamber.Open the lid of the child drum and hung on the other hook.

- Pull and keep the double poly bag which contains material in to the drum loading chamber on the ramp provided.

- Put back the lid on the child drum followed by the inner lid of the sealing system.

- The inner seal gets inflated & stays inflated during the operation.Open the intermediate door and take the material in to the Main Chamber and close the door.

- REFERENCES:

- Main Chamber:

- Dispensing/Sampling chemist should stand in front of the main chamber. Take the material in to the main chamber using glove ports of the main chamber and dispense or sample.

- Proceed for sampling/dispensing activity as per SOP.

- Dispensing/Sampling chemist should Stand in front of pass box chamber.

- The Dispensed or sampled material transferred to the pas box chamber through the liner port using glove ports of the pass box chamber.

- The liner poly bag should connect to the liner port “O” ring.

- Take the dispensed and sampled material into the liner poly bag and tie the liner bag in two places with a provision for easy cutting of the material bag through glove ports.Open the pass box chamber door and take the material outside.

- Note down activity details “Sampling” in case of Sampling and “Dispensing” in case of dispensing respectively in format.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/procedure-for-operation-of-dispensing-sampling-isolator/

REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

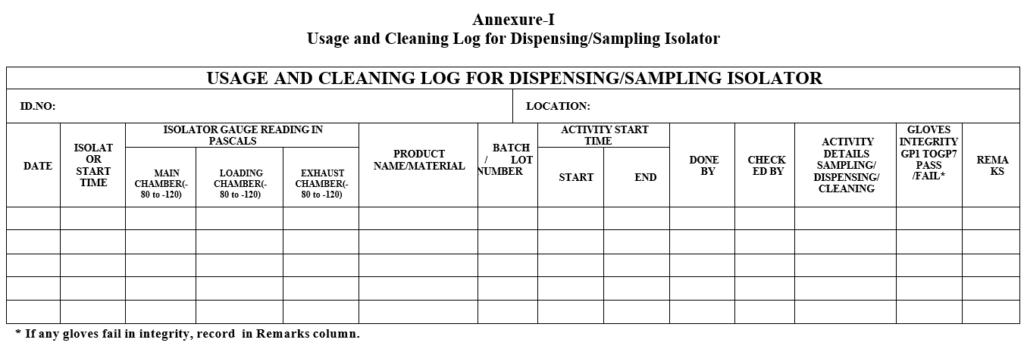

| Annexure-I | Usage and Cleaning Log for Dispensing/Sampling Isolator |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Warehouse

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| PGH | : | Pharmaguidehub |

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| QA | : | Quality Assurance |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

Usage and Cleaning Log for Dispensing/Sampling Isolator

Frequently Asked Question ?

Q: What checks should be done before starting the operation?

A: Ensure cleanliness, closed doors, open utilities, connected catch pot, glove integrity, inflation, and record observations.

Q: How often should gloves be replaced?

A: Every 3 years or if damaged.

Q: How do you start the Isolator?

A: Turn on power, press POWER RESET and FAN START buttons, observe green “HEALTHY CONDITION” light.

Q: What happens during a power failure?

A: System shuts down, press POWER RESET and FAN START buttons to resume operation upon power return.

Q: What are the acceptable magnehelic gauge readings?

A: -80 to -120 Pascals for main chamber, drum loading, and pass box (exhaust).

Q: What happens if a leak occurs?

A: Isolator switches to containment breach mode (red light, yellow lamp, audio alarm).

Q; What actions should be taken in containment breach mode?

A: Turn off Isolator, inform maintenance for rectification, mode resets automatically when pressure is restored.

Q: How do you remove the outer seal of the mother drum?

A: Set outer/inner seal button to outer, deflate door with button, and remove the outer lid.

Q: How do you insert the mother drum into the inflatable gasket?

A: Press ENERGISE and DRUM RAISE buttons, operate SLIDE IN button.

Q: How do you activate the inner seal and remove the inner lid?

A: Set button to inner, press inner seal deflate button, remove inner lid immediately.

Q: Where does the dispensed/sampled material go?

A: It is transferred to the pass box chamber through the liner port.

Q: How should the liner bag be secured?

A: Connect it to the liner port “O” ring, tie it in two places with room for cutting.

Q: What information should be recorded?

A: Activity details (“Sampling” or “Dispensing”) in the designated format.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/procedure-for-operation-of-dispensing-sampling-isolator/