- OBJECTIVE:

To describe a standard operating procedure for periodical testing, servicing, and refilling of fire Extinguishers.

- SCOPE:

This Procedure is applicable for periodical testing, servicing, and refilling of fire Extinguishers at {Company Name} {Company Location}.

- RESPONSIBILITY:

- All the employees working in the plant.

- Safety In-charge to ensure the Compliance of the procedure.

- ACCOUNTABILITY:

QA Manager shall be accountable for Approval & Implementation of SOP.

- PROCEDURE:

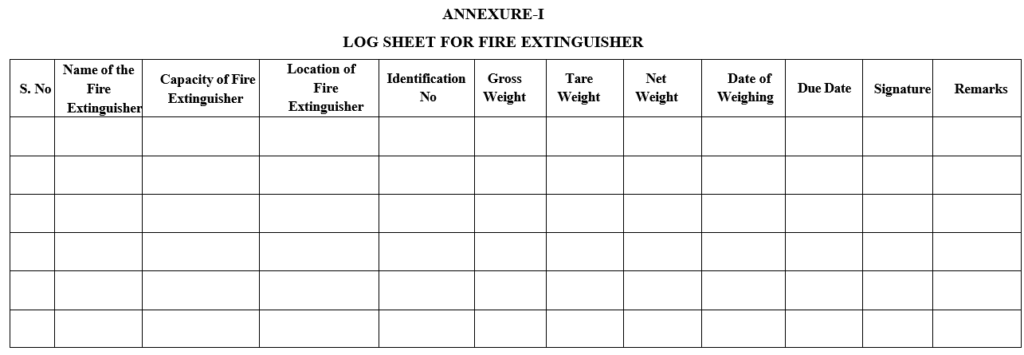

- The log sheet shall be recorded as per Annexure-I for each fire extinguisher, whenever any testing, servicing & refilling is carried out.

- Testing, Servicing & refilling activities on site (Except refilling of CO2 Fire Extinguishers and hydro pressure test of all fire extinguishers).

- Fire Extinguishers services shall be carried out a frequency of once in 2 months and stick as per the label after servicing.

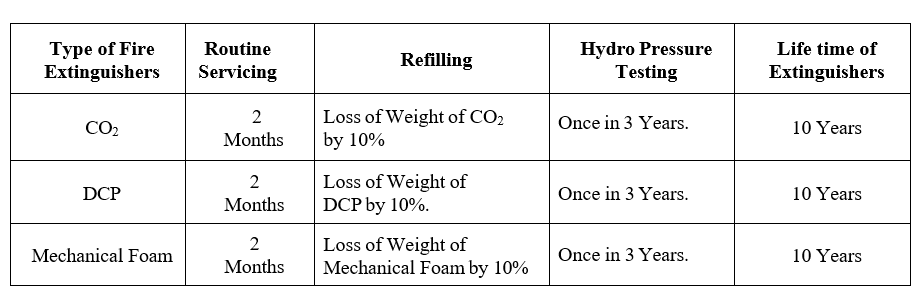

- Periodical activities carried out on the different types of Fire Extinguishers.

- Weight of fire extinguishers must be checked once in two months, and if a drop in weight of 10%, the fire extinguisher must be sent for re-filling.

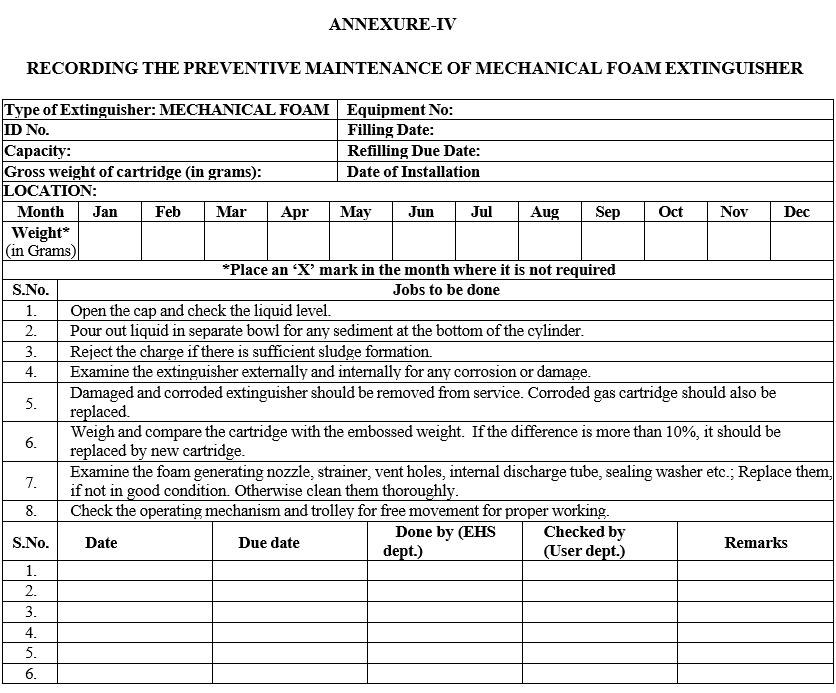

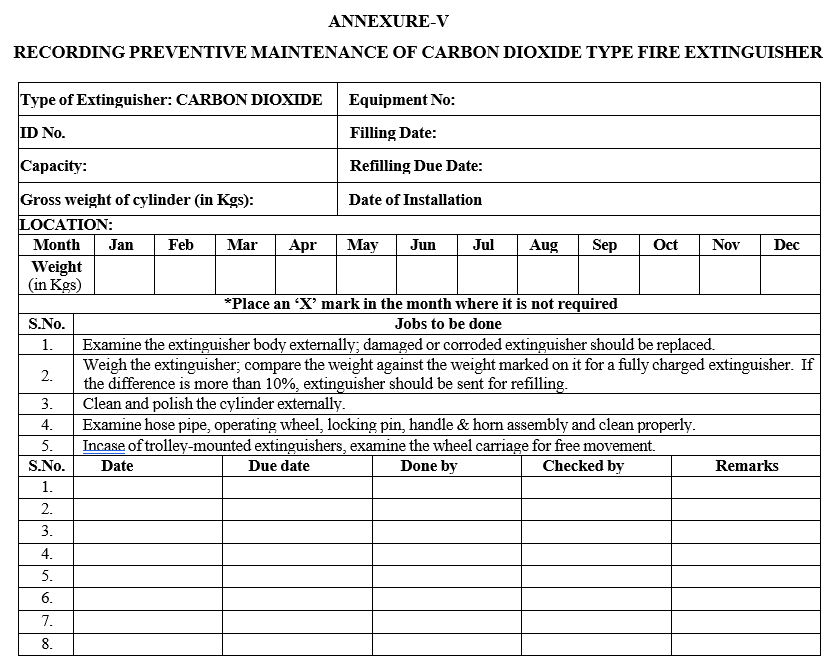

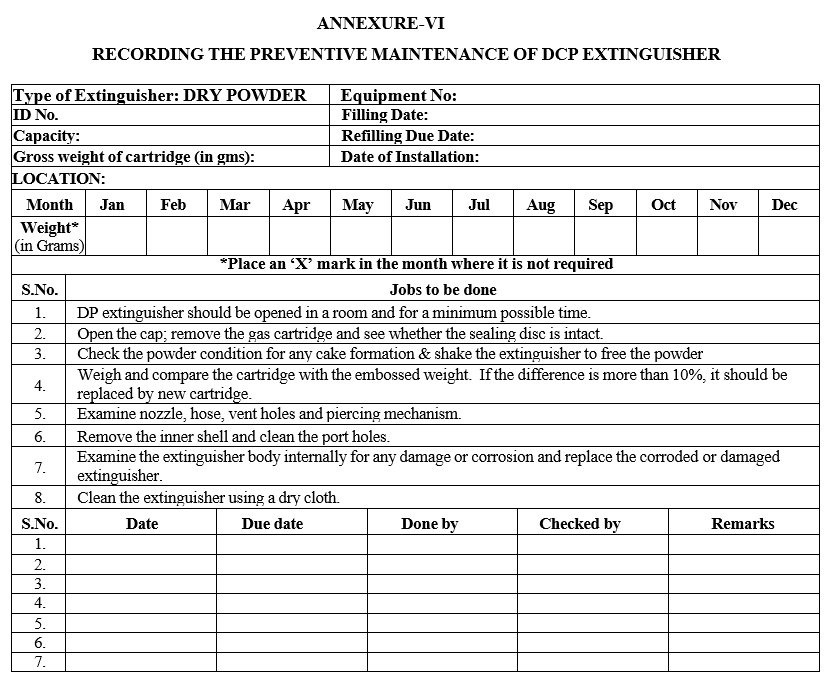

- All extinguishers must be checked for content, release mechanisms, Maintenance, and safety pins once in every two months. Preventive maintenance of Mechanical Foam Extinguisher in (Annexure-IV), Preventive maintenance of Carbon dioxide type fire extinguisher in (Annexure-V) and preventive maintenance of DCP extinguisher in (Annexure-VI).

- Maintenance of all fire extinguishers must be carried out by EHS department, and it must be checked by the user department.

- Fire extinguisher installed in such a way that the top of extinguisher is at a height of 5 feet or less.

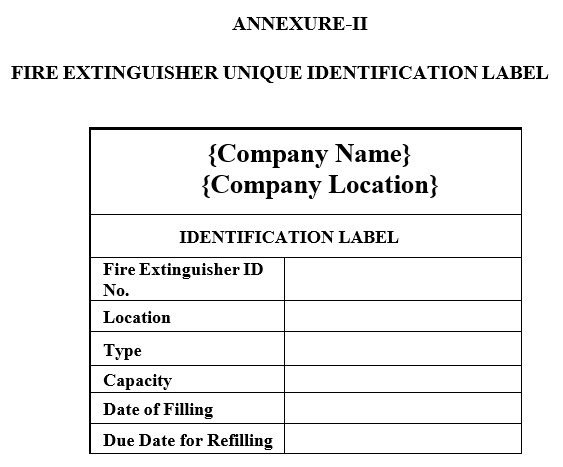

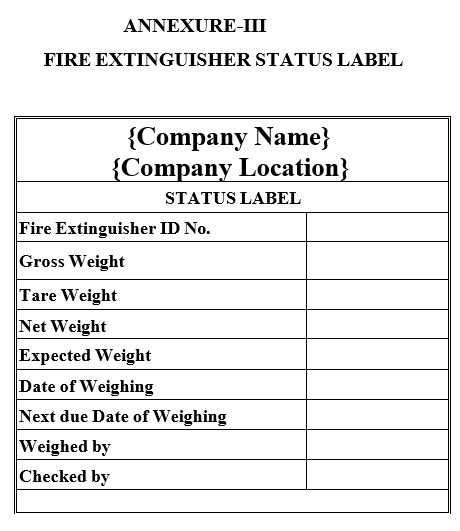

- Each fire extinguisher must have a unique identification label (Annexure-II), and a status label (Annexure-III) indicating the last checked date, and net weight of extinguishing media.

- The10% of extinguishers must be kept as spare.

- The life of an extinguisher is ten years from the date of procurement. The extinguisher must be used for training, and empty extinguisher must be scrapped after ten years.

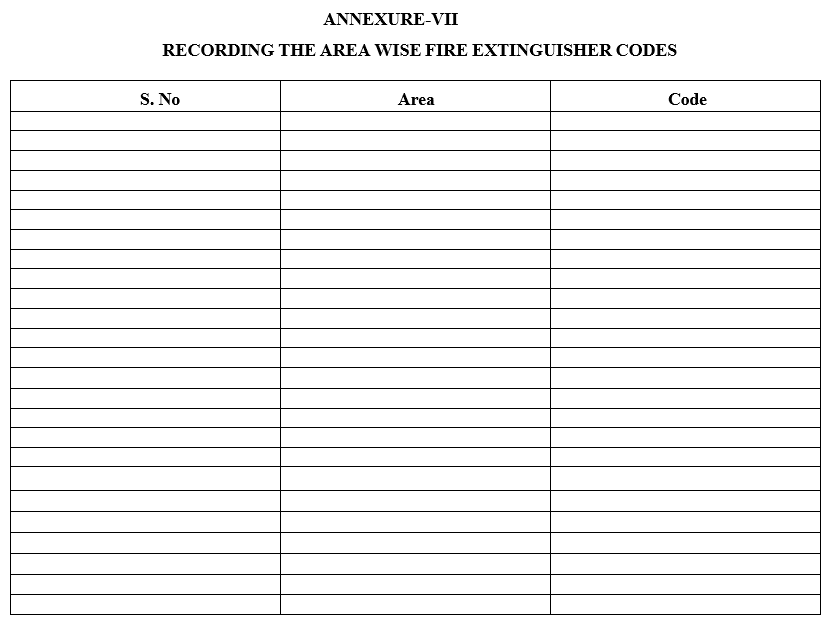

- EHS department should maintain a master list and Codes of all fire extinguishers in the site Area of codes in (Annexure-VII.These Formats are update and upload in DMS only. No need to change Control for further updation.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Log sheet for Fire Extinguisher |

| Annexure-II | Fire extinguisher unique identification label |

| Annexure-III | Fire extinguisher Status label |

| Annexure-IV | Recording the preventive maintenance of Mechanical Foam Extinguisher |

| Annexure-V | Recording preventive maintenance of Carbon dioxide type fire extinguisher |

| Annexure-VI | Recording the preventive maintenance of DCP extinguisher |

| Annexure-VII | Recording the Area wise Fire Extinguisher Codes |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

| Controlled Copy No. 01 | : | Safety Health & Environment |

| Master Copy | : | Quality Assurance Department |

- ABBREVIATIONS:

SOP : Standard Operating Procedure

DCP : Dry Chemical Powder

CO2 : Carbon dioxide

EHS : Environment, Health & Safety

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

LOG SHEET FOR FIRE EXTINGUISHER

ANNEXURE-II

FIRE EXTINGUISHER UNIQUE IDENTIFICATION LABEL

ANNEXURE-III

FIRE EXTINGUISHER STATUS LABEL

ANNEXURE-IV

RECORDING THE PREVENTIVE MAINTENANCE OF MECHANICAL FOAM EXTINGUISHER

ANNEXURE-V

RECORDING PREVENTIVE MAINTENANCE OF CARBON DIOXIDE TYPE FIRE EXTINGUISHER

ANNEXURE-VI

RECORDING THE PREVENTIVE MAINTENANCE OF DCP EXTINGUISHER

ANNEXURE-VII

RECORDING THE AREA WISE FIRE EXTINGUISHER CODES