- OBJECTIVE:

To lay down the procedure for Validation of different types of analytical test procedures.

- SCOPE:

This SOP is applicable for the procedure for Validation of different types of analytical test procedures at {Company Name} {Location}.

- RESPONSIBILITY:

- Officer/Executive/Designee Quality Control – Shall be responsible for conducting validation of analytical test procedures as per SOP.

- Head/Designee Quality Control – Shall be responsible for ensuring compliance as per SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

- All analytical methods shall be validated in accordance with current ICH Q1 requirements.According to the current good manufacturing Practice Regulations [ (21CFR 211.194) (a) (2)], users of analytical methods described in (Compendial Method) are not required to validate accuracy and reliability of these methods, but merely to verify their suitability under actual conditions of use.

- Analytical methods used for evaluation of cleaning process validation shall be done at Quality Control in accordance to the above guidelines.

- Cleaning Validation Procedure:

- Specificity:

- Specificity is the ability to assess unequivocally the analyte in the presence of components which may be expected to be present.

- Demonstrate the separation of the analyte from available placebo, Diluent, blank(swab) and placebo with standard solution using the Instrument.

- System Precision:

- The precision of an analytical procedure expresses the closeness of the agreement (Degree of scatter) between a series of measurements.

- As a part of method validation, a minimum of 6 injections of the standard preparation with an RSD of ≤ 5.0 % is recommended.

- Method Precision:

- The precision of an analytical procedure expresses the closeness of the agreement (Degree of scatter) between a series of measurements obtained from a multiple sampling of the same homogeneous sample under the prescribed conditions.

- As a part of method validation, a minimum of 6 injections of the standard preparation with an RSD of ≤ 5.0 % is recommended.

- Linearity:

- The linearity of an analytical procedure is its ability (with a given range) to obtain test results which are directly proportional to the concentration (amount) of analyte in the sample.

- The Correlation coefficient should be greater than 0.99.

- Limit of detection:

- The limit of detection of an individual analytical procedure is the lowest amount of the analyte in a sample which can be detected but not necessarily quantified as an exact value.

- Calculate LOD by using (3.3 x Steyx) / slope. Prepare and inject LOD solution accordingly. The % RSD should not be more than 33.0%.

- Limit of Quantification:

- The Quantification limit of an individual analytical procedure is the lowest amount of the analyte in a sample which can be quantitatively determined with a suitable precision and accuracy. The Quantification limit is a parameter of quantitative assays for low levels of compounds in sample matrices and is used particularly for the determination of impurities and/or degradation products.

- Calculate LOQ by using (10 x Steyx) / slope. Prepare and inject LOQ solution (accordingly. The % RSD should not be more than 10.0 %.

- Percentage Recovery:

- Standard Solutions: Prepare standard solutions corresponding to approximately 50%, 100% and 150% of Acceptance Limit concentration as per the test procedure.

- Spiked Swab solution: Prepare spiked swab solutions corresponding to approximately 50%, 100% and 150% of Acceptance Limit as per the test procedure.

- Calculate the % Recovery of spiked swab using the following formula.

- Specificity:

% Recovery = (Spiked swab Area / Average Standard Area) x 100

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/analytical-cleaning-method-validation/

- Average % Recovery should be not less than 75%. In case of discrepancy repeat the experiment. If these criteria are still not met, investigate the reason.

- Numbering of ACMV protocol and report:

- Analytical Cleaning Method validation Protocol number consists of 15 characters.

- Numbering of ACMV protocol and report:

ACMVP/QC/YY-XXX

where

| ACMVP | : | Analytical Cleaning Method Validation protocol |

| / | : | slash |

| QC | : | Quality control |

| / | : | slash |

| YY | : | Current year |

| – | : | Dash |

| XXX | : | three digits serial number starts from 001,002 and so on |

E.g.: First Analytical Cleaning Method Validation protocol of 2024 in QC shall be given as ACMVP/QC/24-001

- Analytical Cleaning Method validation Report numbering system consist of 15 characters

ACMVR/QC/YY-XXX

where

| ACMVR | : | Analytical Cleaning Method Validation report |

| / | : | slash |

| QC | : | Quality control |

| / | : | slash |

| YY | : | Current year |

| – | : | Dash |

| XXX | : | three digits serial number starts from 001,002 and so on |

E.g.: First Analytical Cleaning Method Validation report of 2024 in QC shall be given as ACMVR/QC/24-001.

- The Analytical Cleaning Method validation Protocol and Report along with supporting data shall be submitted to QA.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Analytical Cleaning Method validation Record |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Quality Control

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| HPLC | : | High Performance Liquid Chromatography |

| RSD | : | Relative standard deviation |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

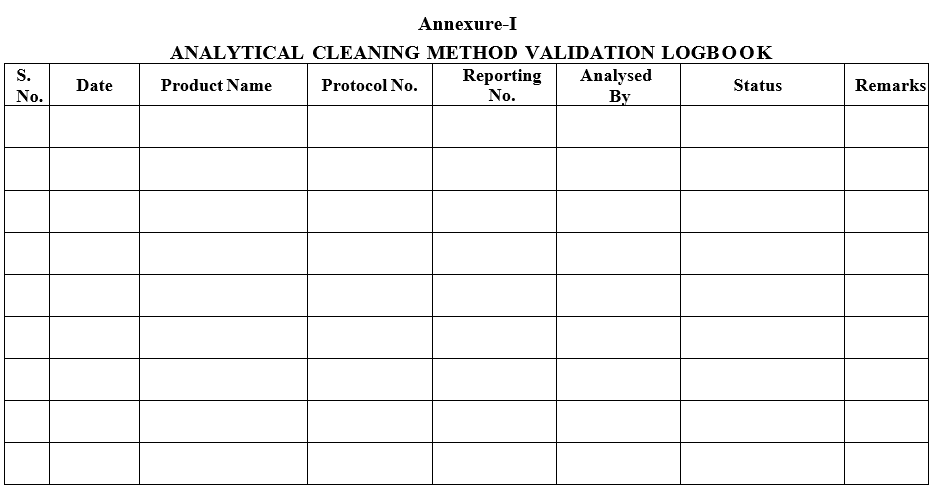

Annexure-I

ANALYTICAL CLEANING METHOD VALIDATION LOGBOOK

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/analytical-cleaning-method-validation/