- OBJECTIVE:

To lay down the procedure for Calibration of auto titrator and electrodes.

- SCOPE:

- This SOP is applicable to the procedure for Calibration of auto titrator and electrodes at {Company Name} {Location}.

- RESPONSIBILITY:

- Officer/Executive/Designee Quality Control – Shall be responsible for calibration of instrument as per SOP.

- Head/Designee Quality Control – Shall be responsible for ensuring compliance as per SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

- Calibration of burette:

- Operate the instrument as per Sop, Rinse well the burette and fill the Burette with purified water.Take a clean, dry 10ml volumetric flask.

- Weigh the volumetric flask and note down the weight as W1.

- Set the dispense volume as 1 ml and dose the water into the Volumetric flask.

- Weigh the volumetric flask with water and note weight as W2.

- Repeat the above 3 steps for volumes 2,3,4,5,6,7,8,9,10 respectively.Mread = W2 – W1

- Vactual = Mread x Density

- Calculate the relative error using the formula

- Relative error = (Vactual –Vset) x 100/Vset

- Density calculation:

- Take a pycnometer and note down the empty weight (W1).

- Fill the pycnometer with water, close the stopper provided and wipe off the excess water.

- Now note down the weight of pycnometer with water at 25°C (W2).

- Weight per ml of water = (W2-W1)/Volume of Pycnometer.

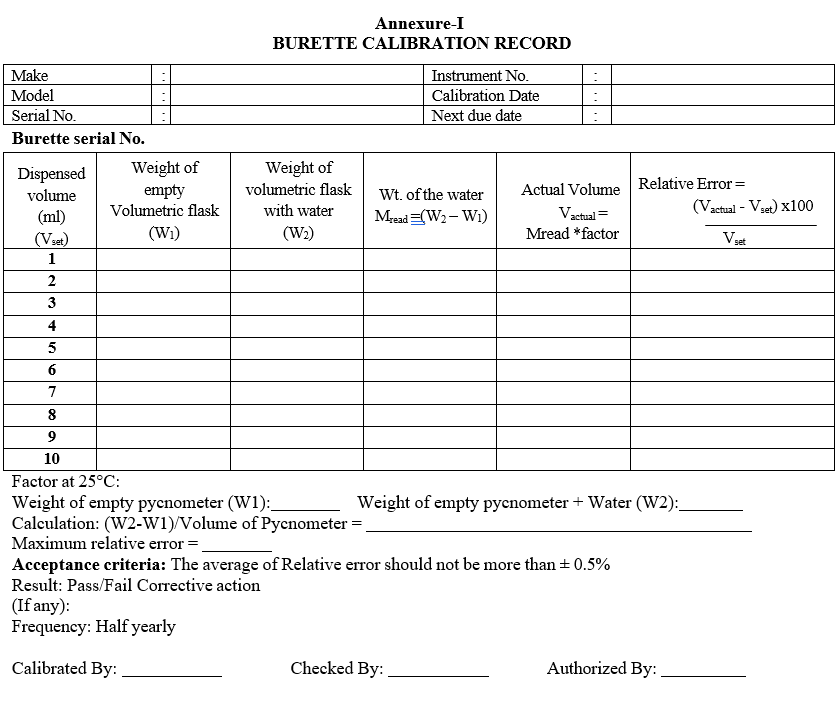

- Enter the details of calibration in calibration record as per format-I.

- Acceptance criteria: the average of Relative error should not be more than ± 0.5%

- Auto titrator calibration:

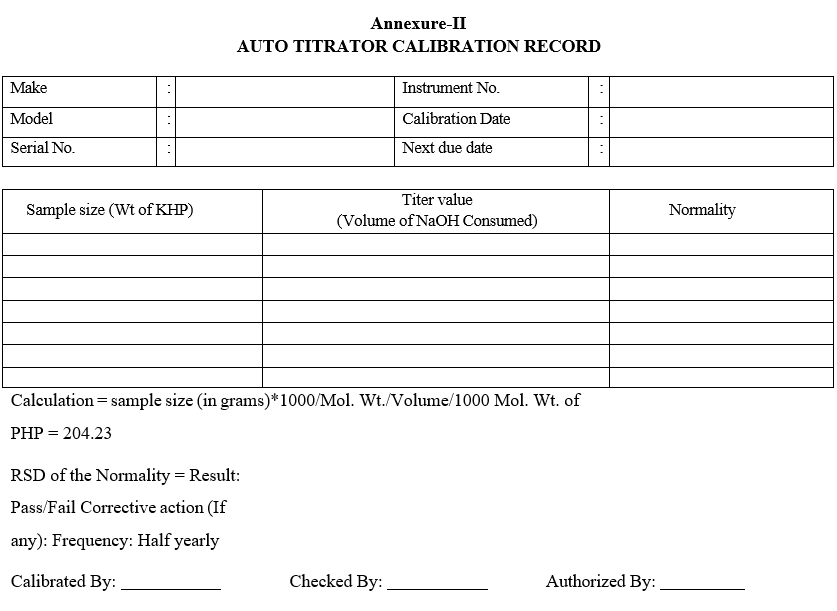

- Select a standard titration (KHP versus NaOH) suggested by Metrohm.Prepare 0.1M NaOH solution and perform the standard titration for five times.

- Calculate the molarity of NaOH for five titrations.

- Calculate the RSD for molarity using the formula RSD = Standard Deviation % 100 Mean

- Acceptance criteria: RSD value should not be more than ± 0.5%.

- Enter the details in calibration record as per format-II.

- If the calibration is not within the specified limits repeat the calibration.

- Report the Results to the department head for appropriate action.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/calibration-of-autotitrator-and-electrodes/

- REFERENCES:

Not Applicable

- ANNEXURES:

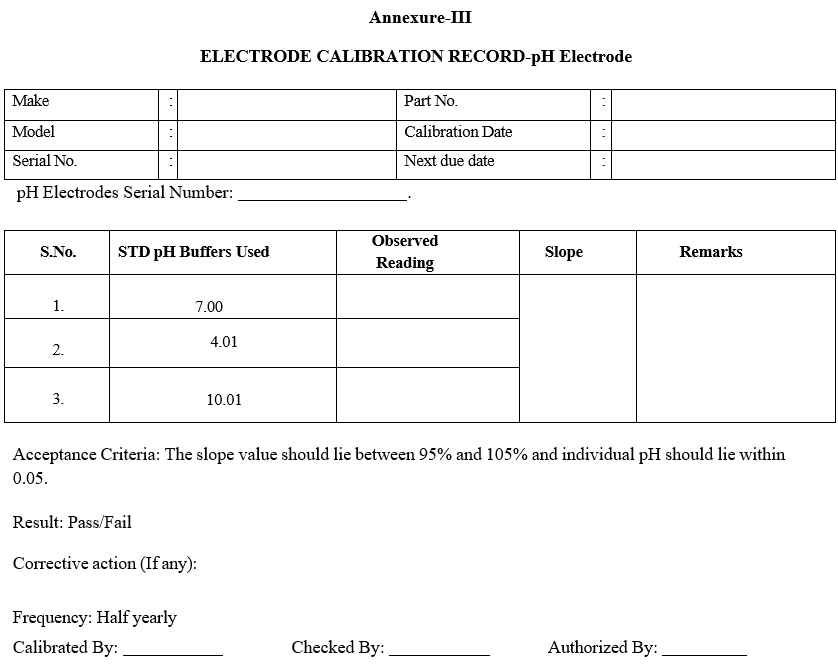

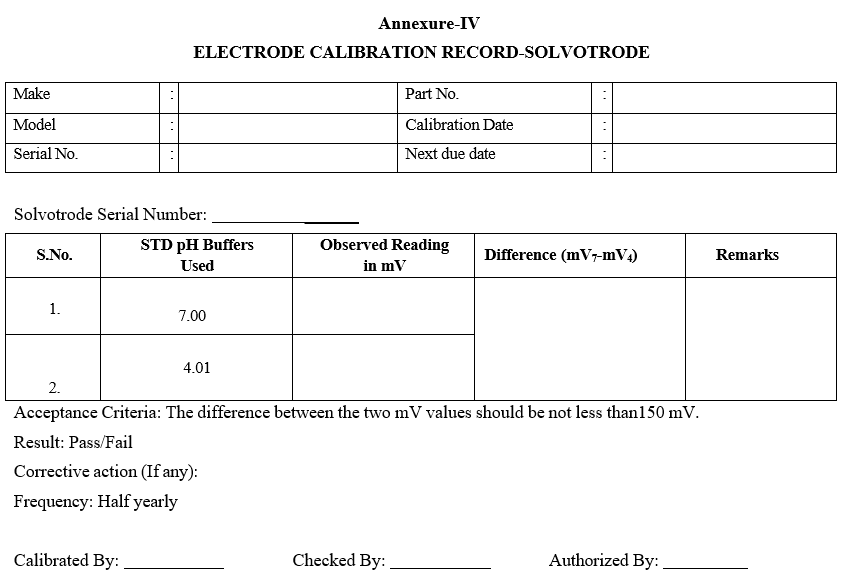

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Burette calibration record |

| Annexure-II | Auto titrator calibration record |

| Annexure-III | Electrodes calibration record-pH |

| Annexure-IV | Electrodes calibration record-Solvotrode |

| Annexure-V | Electrodes calibration record-Combined Ag ring |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Quality Control

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| GTP | : | General Test Procedure |

| QC | : | Quality Control |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

BURETTE CALIBRATION RECORD

Annexure-II

AUTO TITRATOR CALIBRATION RECORD

Annexure-III

ELECTRODE CALIBRATION RECORD-pH Electrode

Annexure-IV

ELECTRODE CALIBRATION RECORD-SOLVOTRODE

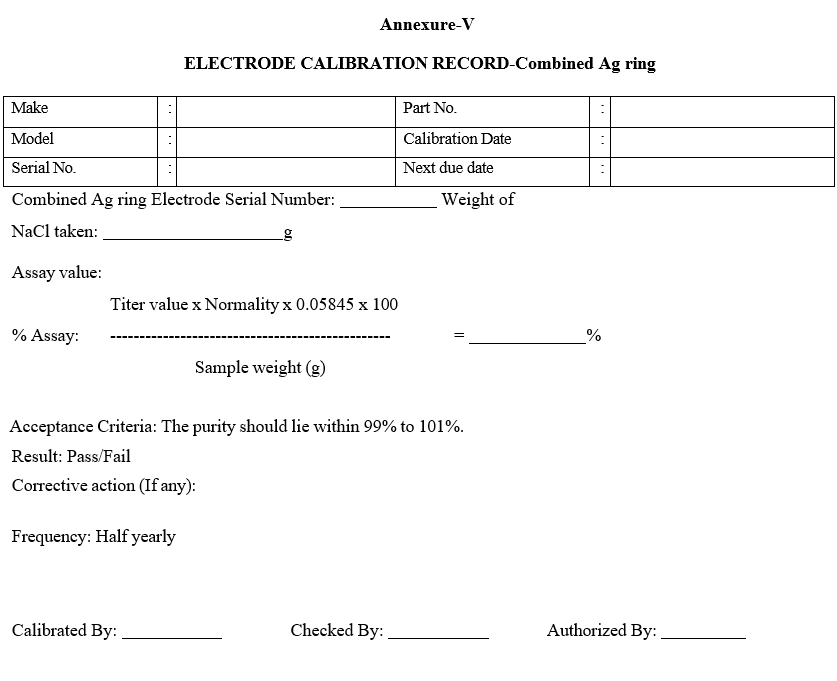

Annexure-V

ELECTRODE CALIBRATION RECORD-Combined Ag ring

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/calibration-of-autotitrator-and-electrodes/