- OBJECTIVE:

- To describe a standard operating procedure for collection, detoxification, and disposal of effluent.

- SCOPE:

- This Procedure is applicable for collection, detoxification, and disposal of effluent at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Assistant– SHE.

- In charge – SHE.

- Assistant– Maintenance

- ACCOUNTABILITY:

- QA Manager shall be accountable for Approval & Implementation of SOP.

- PROCEDURE:

- Procedure for collection, detoxification, and disposal of effluent.

- Collect process Effluents in receiving tank from Production through closed pipe lines by gravity.

- Transfer the effluent into deactivation reaction tank through the transfer pump from the collection tank.

- Prepare and keep ready the recommended volume of detoxifying agent (4%sodium hypochlorite solution) in dosing container based on measured effluent volume.

- SHE personnel should use all PPE while performing deactivation activity.

- Add detoxifying solution in required quantity(add 2 liters of 4%sodium hypochlorite solution in to approximately 20liters of liquid waste) into deactivation tank through dosing mechanism and perform detoxification activity in the deactivation tank.

- Keep under maintenance for 48 Hrs. for effective deactivation in the deactivation tank.

- After completion of maintenance period transfer the deactivation /detoxified effluent in to storage tank.

- The detoxified effluent through transfer pump is transferred from storage tanks into Pre- treatment tank at Main ETP for further treatment and disposal.

- Check & ensure the level of the sumps should not cross 3/4th level of its capacity.

- Preparation of 4% Sodium Hypo Chlorite Solution:

- If Sodium Hypo Chlorite Solution received in the strength of 4 % shall be directly used for the Deactivation Process.

- If Sodium Hypo Chlorite Solution received in the strength of 6% The following procedure shall be followed:

- To Take 1.3litres of 6% Sodium Hypo Chlorite and add 0.7 Liters of Water to mixed to get 4% Sodium Hypo Chlorite Solution

- REFERENCES:

- Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Effluent Deactivation Log |

| Annexure-II | 4 % Sodium Hypo Chlorite Solution Preparation and Usage Log Sheet |

- DISTRIBUTION:

| Controlled Copy No. 01 | : | Safety Health & Environment |

| Master Copy | : | Quality Assurance Department |

- ABBREVIATIONS:

SOP : Standard Operating Procedure

QC : Quality control

SHE : Safety, Healthy & Environment

F&RD : Formulation and Research Development

API : Active Pharmaceutical Ingredient

ETP : Effluent Treatment Plant

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

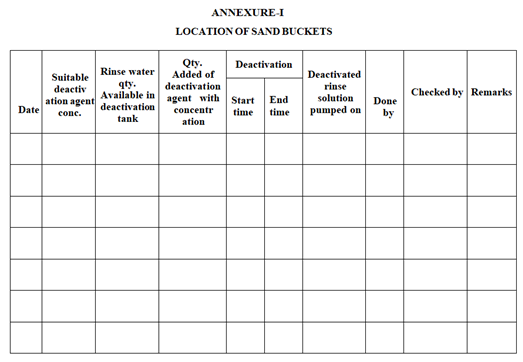

ANNEXURE-I

LOCATION OF SAND BUCKETS

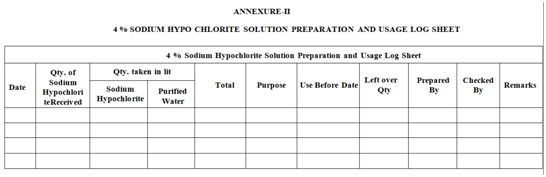

ANNEXURE-II

4%SODIUMHYPOCHLORITESOLUTIONPREPARATIONAND USAGE LOG SHEET