- OBJECTIVE:

To lay down a procedure for Cleaning the service area fresh air filters.

- SCOPE:

This SOP is applicable for Cleaning the service area fresh air filters at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering is responsible for the SOP.

- Executive – Engineering responsible to ensure the SOP.

- Head / Designee– Engineering is responsible for compliance of the SOP.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- PRECAUTIONS

- Filters shall be handled carefully to avoid media damage.

- Before starting filter cleaning, necessary PPE’s shall be worn.

- FILTER DISMANTLING PROCEDURE

- Open the screws and keep in a tray.

- Check the filter condition.

- Check the filter gasket and filter media, if any damage observed in filter media replace the filter.

- CLEANING PROCEDURE

- Dismantle the filters and put the filter into Poly Bag and transfer the filters to the uncleaned filter storage area.

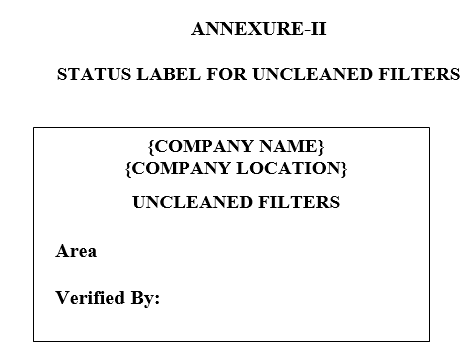

- Filters are identified with “UNCLEANED FILTERS” status label as per Annexure-II on the polythene covers. This status label shall be verified by Engineering Technical Assistant/Executive.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-procedure-for-service-area-fresh-air-filters/

- Remove the filters from the poly bag and keep the poly bags in dustbin.

- Tap the filters gently by hand on floor with upstream (dirty) side facing down to floor to dislodge all loose particles.

- Check the compressed air pressure is regulated to 1.0 to 2.0 Kg/Cm².

- Clean the filters in the filter cleaning equipment with compressed air pressure at about 1.0 to 2.0 Kg/Cm² air directing at an angle towards downstream.

- Clean the filters with potable water at about 0.5 to 1 Kg/Cm² pressure.

- Transfer the cleaned filters to the filter drying equipment.

- Filters are dried in the filter drying equipment by setting the heater temperature to 50ºC.

- Ensure the filters are completely dry, transfer the dried filters to the inspection area and inspect the physical condition of the filters if found damage, replace with a new filter.

- Inspected filters area kept in the poly bags and transferred to cleaned filters hold area.

- Re-install the filters which are kept in new poly bags to the respective area.

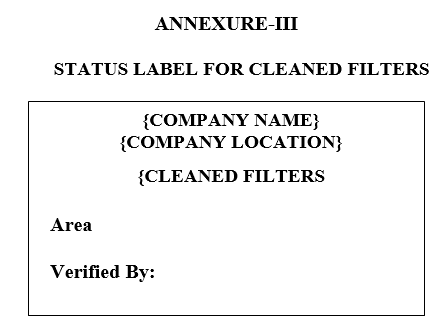

- Filters are identified with “CLEANED FILTERS” status label as per Annexure-III on the polythene covers. This status label shall be verified by Engineering Technical Assistant/Executive.

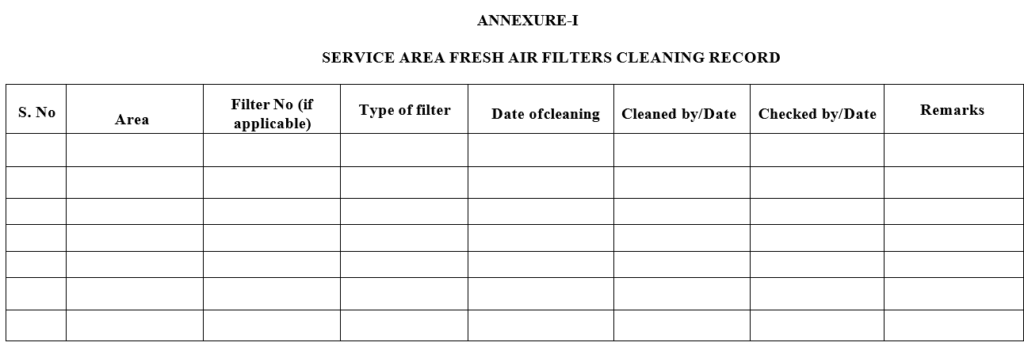

- Record the filter cleaning details in Filter Cleaning Record in Annexure-I.

- The filter cleaning frequency shall be 30 ± 7 days.

- Filter cleaning Area Cleaning Procedure

- After completion of Filter cleaning activity, the area shall be cleaned with water.

- Floor mopping shall be done.

- All filters shall be identified with a unique numbering system.

AA/BBB/001

AA: Indicate Area Name

BB: Indicate rating of the filter

001: Serial No. start from 001, 002,003…….

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Service area fresh air filters Cleaning Record |

| Annexure-II | Status Label for Uncleaned Filters |

| Annexure-III | Status Label for Cleaned Filters |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

SOP : Standard Operating Procedure.

Kg/Cm² : Kilograms per square centimeters.

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

SERVICE AREA FRESH AIR FILTERS CLEANING RECORD

ANNEXURE-II

STATUS LABEL FOR UNCLEANED FILTERS

ANNEXURE-III

STATUS LABEL FOR CLEANED FILTERS

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-procedure-for-service-area-fresh-air-filters/