- OBJECTIVE:

To lay down a procedure for Differential pressure and Integrity test for 0.2 µ filter.

- SCOPE:

This SOP is applicable for Differential pressure and Integrity test for 0.2 µ filter at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant/Executive – To ensure the Differential pressure and Integrity test (bubble point test) of 0.2 µ filter.

- Head/Designee– Engineering shall ensure the compliance as per SOP.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- INTEGRITY TEST OR BUBBLE POINT TEST (BPT) PROCEDURE

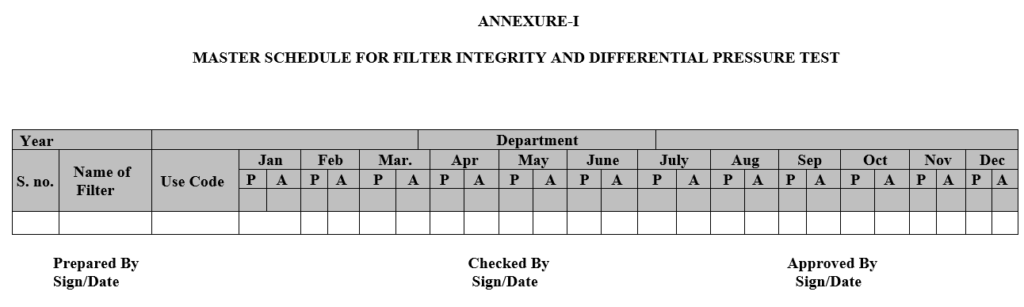

- Perform the Bubble point test as per the Master schedule for the filter integrity /Differential pressure test. Master schedule format as per Annexure-1.

- While removing the filter from user point close the valve and then remove.

- Ensure the availability of compressed air.

- Ensure the Bubble point Test apparatus are calibrated.

- Wet the filter with 30% water and 70% IPA media, as per manufacturer recommendations.

- Ensure that all the connections are secure and tight.

- Connect the compressed air line to the inlet of the 1st air regulator and outlet of the 1st air regulator to inlet of 2nd air regulator and outlet of the 2nd air regulator to filter inlet.

- Open the valve of compressed air line.

- Slowly increase the inlet valve of the BPT apparatus and set the pressure 4.0Kg/ Cm².min at the 1st air regulator.

- Then open the outlet valve of the BPT apparatus (2nd FR unit) and slowly increase the pressure up to 2.5 Kg/Cm².

- Observe the bubbles in the water.

- There shall not be any bubbles coming out before 1.1Kg/Cm2 (16PSIG) as per manufacturer recommendations.

- Initially a few bubbles may be observed.

- If any bubbles are observed continuously below manufacturer recommended value, it indicates that the integrity of the filter has failed.

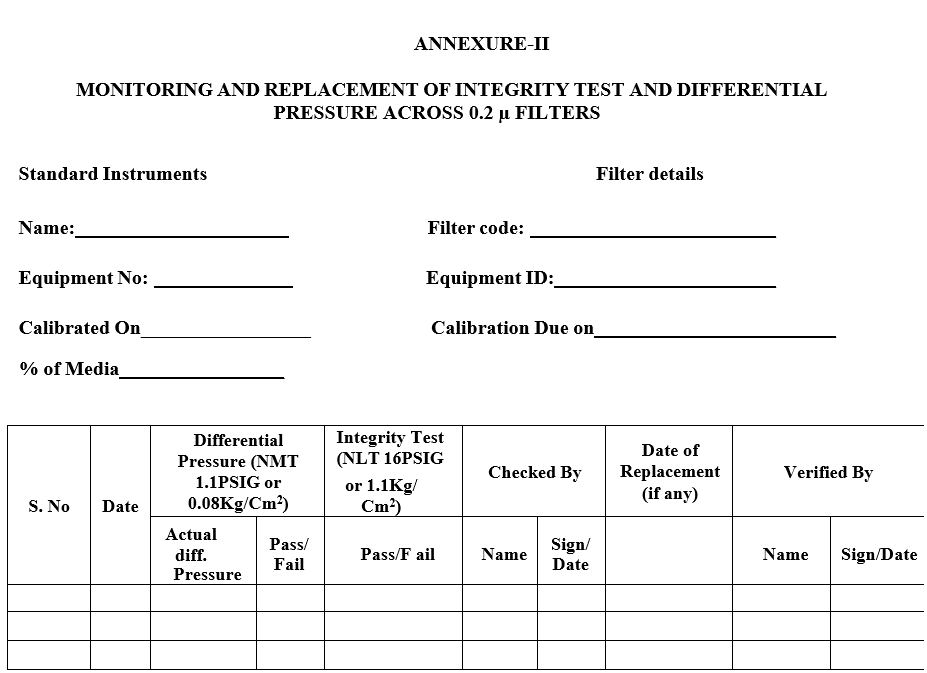

- Replace the filter with a new filter and enter the bubble point test details in the record as per Annexure-2.

- Record the details in the format “Monitoring and replacement of Integrity test and Differential pressure across 0.2 µ filters” in Annexure – 2.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/procedure-for-differential-pressure-and-integrity-test-of-0-2-%c2%b5-filter/

- Differential Pressure across the filter

- Connect the compressed air line to the inlet of the Ist air regulator and outlet of the1st air regulator tube connect to filter. The outlet of the filter tubes connect to the 2nd air regulator inlet and close the outlet of the 2nd air regulator.

- Measure the differential pressure across the filter by using a suitable calibrated Pressure gauge located in the second air regulator.

- The differential pressure should not be greater than the limit 0.08 Kg/Cm2 (1.1PSIG) as per manufacturer recommendations.

- The differential pressure should not be greater than the limit 0.08 Kg/Cm2 (1.1PSIG) as per manufacturer recommendations.

- Assign the point -of -use code to the 0.2µ filter for identification.

- Numbering of Filters

Unique filter number shall be given.

For e.g.

AAA/F1-00

AAA: Indicates filter Code.

F1: Indicates numeric denotes the serial number of the filter installed on the point of use.

00: indicating the number of times the filter is replaced

- Frequency:

- For New filter before installation Differential pressure and Integrity test shall be performed and details shall be entering in Master schedule.

- For regular use filters Differential pressure and Integrity test shall be performed once in Six months within allocable grace period of ± 7 days.

- As per Master Schedule Integrity test, differential pressure to be performed. If this test is not performed as per master schedule and within the grace period, then engineering department shall raise the PNC and the filter integrity shall be performed immediately. The same shall the mentioned in the remarks column of Annexure-I.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Master schedule for filter integrity and differential pressure test |

| Annexure-II | Monitoring and replacement record of Integrity Test and Differential pressure across 0.2µ filters |

| Annexure-III | Integrity and DP test – Label |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

SOP : Standard Operating Procedure.

BPT : Bubble point test.

DP : Differential Pressure.

PSIG : Pounds per Square Inch Gauge.

PNC : Process Non-Conformance.

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

MASTER SCHEDULE FOR FILTER INTEGRITY AND DIFFERENTIAL PRESSURE TEST

ANNEXURE-II

MONITORING AND REPLACEMENT OF INTEGRITY TEST AND DIFFERENTIAL PRESSURE ACROSS 0.2 µ FILTERS

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/procedure-for-differential-pressure-and-integrity-test-of-0-2-%c2%b5-filter/