- OBJECTIVE:

To lay down a procedure for testing integrity of Vent filters in Purified water system.

- SCOPE:

This SOP is applicable for testing integrity of Vent filters in Purified water system at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering shall be responsible for integrity of vent filters in purified water system.

- Executive / Manager – Engineering shall be responsible to ensure the compliance with respect to purified water system.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- Remove the Vent filter with housing from RO Product water storage tank Purified water distribution tank Electric Vent filters as follows.

- For Vent filter disconnect the Temperature sensor respectively.

- Remove the Electric Vent filter insulation cover.

- Remove the 0.2 µ filter from the SS housing.

- For vent filter remove with SS housing by removing the triclover clamps.

Bubble Point Test (BPT) Procedure:

- Ensure the availability of compressed air.

- Wet the filter with water and IPA media (60% IPA / 40% water) as per manufacturer’s recommendations.

- Ensure that all the connections are secure and tight.

- Connect the compressed air line to the inlet of the Ist air regulator and outlet of the 1st air regulator tube connect to inlet of 2nd air regulator and outlet of the 2nd air regulator connect to filter inlet.

- Open the valve of compressed air line and slowly increase the inlet valve of the BPT apparatus and set the pressure 1.5 Kg/cm2 in 1st air regulator.

- Then open the outlet valve of the BPT apparatus (2nd regulating unit) and slowly increase the pressure up to 1.5 kg/cm².

- Observe for any bubbles in the water.

- Initially few bubbles may be observed, after stabilization that ensure no bubbles should be observed visually.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/integrity-test-for-vent-filters-in-purified-water-system/

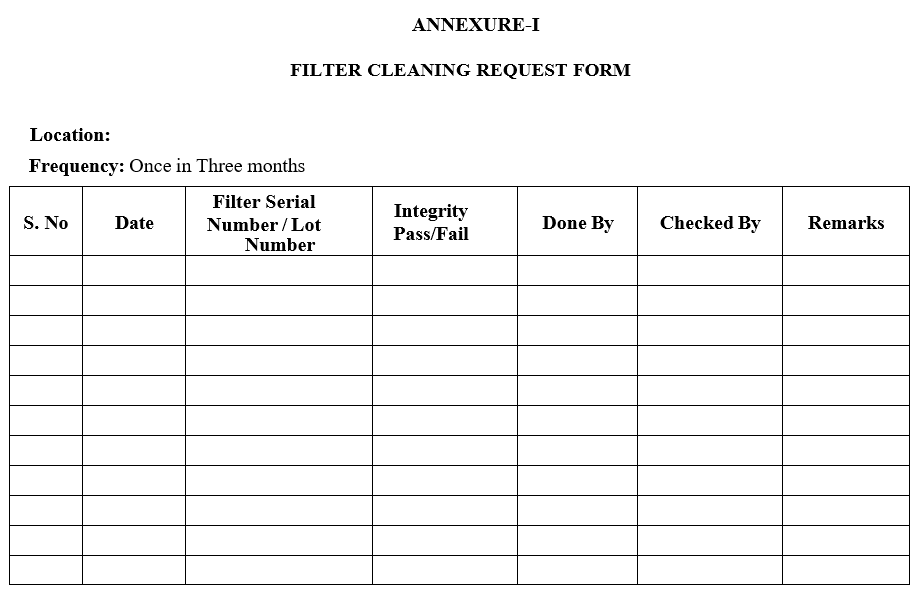

- Record the details in the format ” vent filter integrity test record” in Annexure-I.

- If the filter is failed in the integrity test, replace with the same and enter in the record.

- Re-fix the vent filter to the equipment.

- Integrity Test Frequency: Once every three months.

- Replacement of Vent filters shall be done every year as per respective SOP. At the time of replacement of all Vent filters, Vent filter integrity tests shall be performed before and after replacement of the filter and the details shall be recorded in Annexure-I.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Vent Filter Test Record. |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

RO : Reverse Osmosis

BPT : Bubble point test

IPA : Isopropyl Alcohol

µ : Micron

Kg/cm2 : Kilogram per square centimeter

SS : Stainless Steel

NA : Not Applicable

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

FILTER CLEANING REQUEST FORM

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/integrity-test-for-vent-filters-in-purified-water-system/