- PROCEDURE:

- Alliance HPLC with EMPOWER software

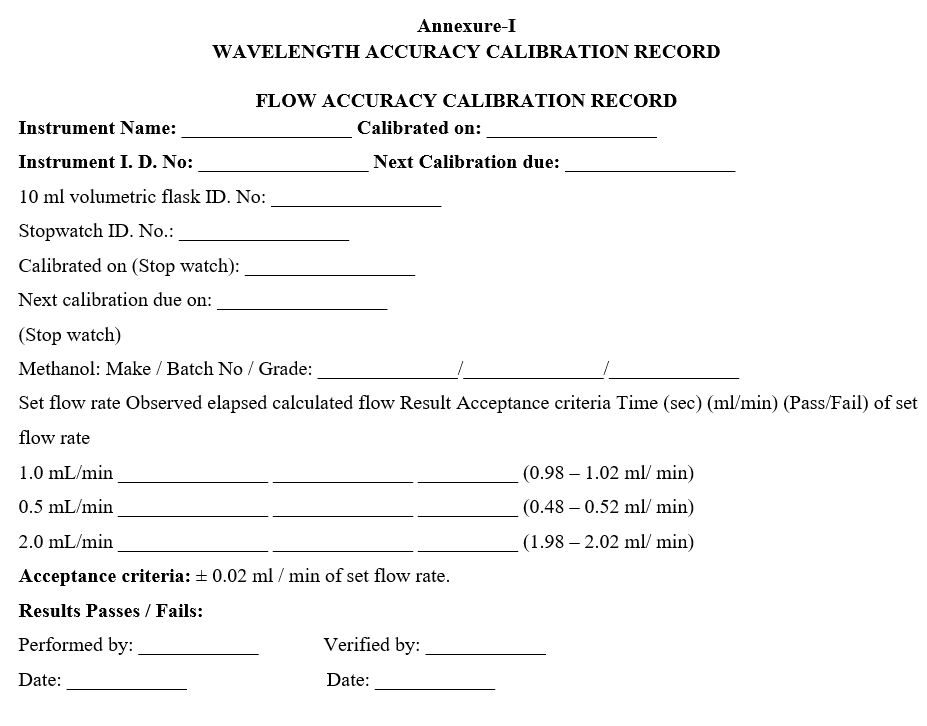

- FLOW ACCURACY TEST:

- Fix the Union/Restriction Capillary in the column compartment.

- Keep degassed water (Milli Q) in channel ‘A’ and prime the channel thoroughly.

- Keep the degasser mode on and stabilize for about 1 hour with a flow rate of 1 ml /min.

- Take a 10 ml calibrated volumetric flask and dry it.

- When the flow and pressure are stable, insert the outlet tubing into the volumetric flask and immediately start a calibrated stopwatch.

- Stop the stopwatch when the bottom of the meniscus reaches the 10 ml mark on the flask.

- Record the elapsed time in seconds.

- Calculate the flow rate using the following equation:

- Calculated flow rate = (10.00 ml/ measured time in seconds) x 60

- Similarly test the flow rate accuracy with flow rates 0.5 mL/min and 2.0 mL/min and record the calculated flow rate.

- Acceptance criteria:

- ± 0.02 mL/min of set flow rate.Record the results in calibration record as per Format – I.

- Calibration schedule:

- Once in 6 months and after any major maintenance job.

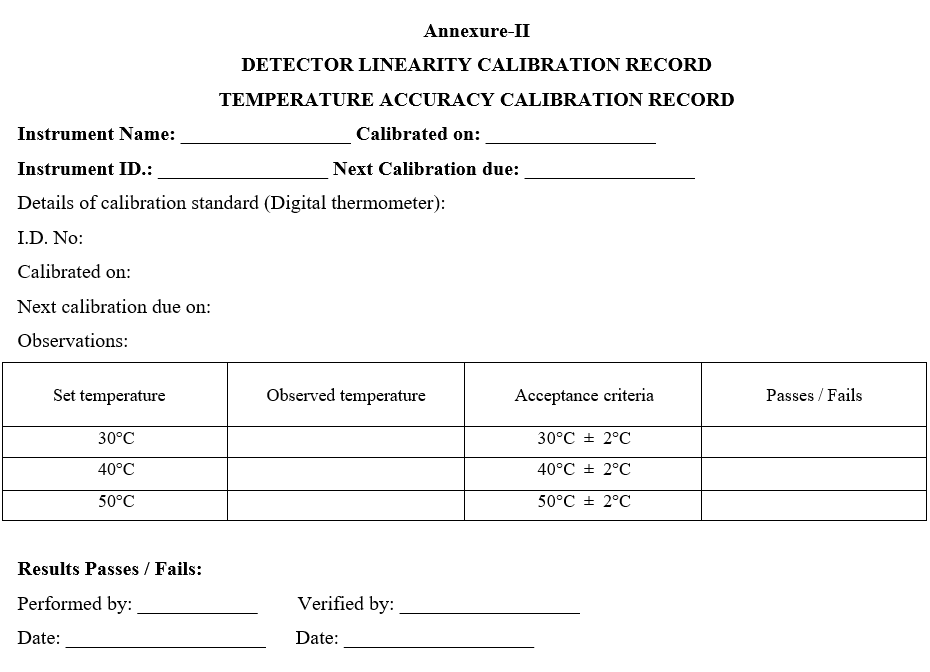

- TEMPERATURE ACCURACY:

- Set column oven temperature to 30ºc and stabilize for about half an hour.Keep the temperature probe of Digital thermometer inside the oven compartment and allow to stabilize the reading.

- After stabilization of the temperature, note down the reading as per Format-II.

- Repeat the steps above 3 steps for the temperatures 40°C and 50 °C respectively.

- Acceptance criteria: ± 2ºC of set temperature.Record the results in calibration record as per Format-II.

- Calibration schedule: Once in 6 months and after any major maintenance job.

- DETECTOR CALIBRATION:

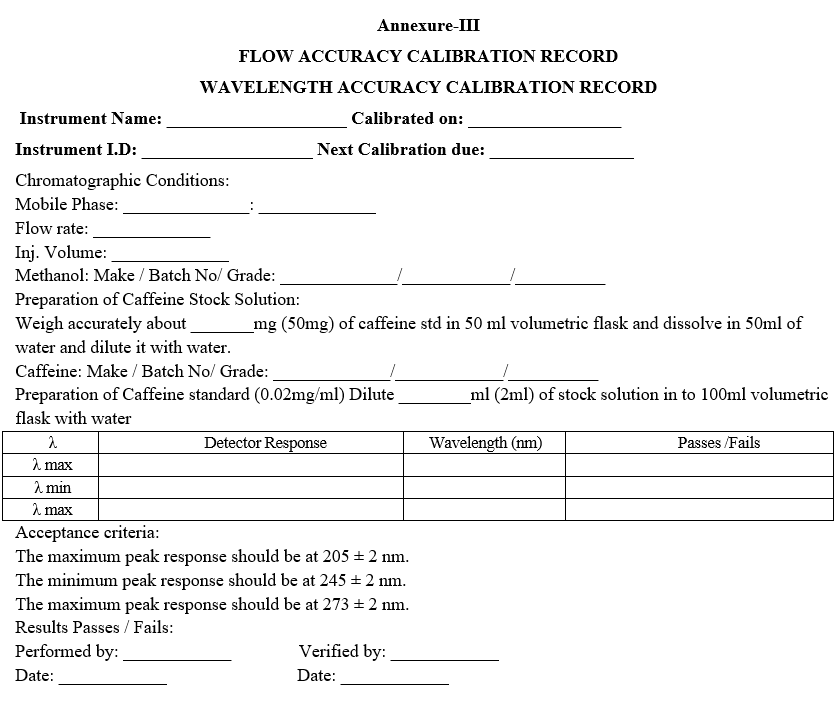

- Wavelength Accuracy:

- Operate the instrument as per SOP

- Weigh accurately 50 mg of caffeine working standard into a 50ml volumetric flask, dissolve and dilute to 50 ml with water. Dilute 2 ml of the above solution to 100 ml with water (0.02 mg/ml).

- Prepare filtered and degassed mobile phase mixture of Water and methanol in the ratio of 70: 30.

- Fix the Column (Symmetry C18, 4.6mm x 75mm 3.5µm) in the column compartment.

- Place the mobile phase and stabilize for 30 minutes at a flow rate of 1.0 ml/min.

- Set the wave length as 201 nm and Column temperature as 35°C.

- Inject the 0.02mg/ml solution each time with the following parameters by varying the wavelength from 201 nm to 209 nm, 241 nm to 249 nm and 269nm to 277 nm with 1 nm frequency. Run time 5 min and injection volume 10µl, Perform duplicate injections at all wavelengths.

- Inject 0.02 mg/ml of caffeine in duplicate and after completion of the run, extract the spectrum from 201 nm to 209 nm, 241 nm to 249 nm and 269nm to 277 nm.

Acceptance Criteria: The maximum peak area response should be at 205 ± 2 nm. The minimum peak area response should be at 245 ± 2 nm. The maximum peak area response should be at 273 ± 2 nm.

- Enter the results in calibration record as per Format-III.

- Calibration schedule: Once in 6 months and after any major maintenance job.

Note: If the calibration is performed continuously, no further stabilization is required for injector linearity, detector response linearity and wavelength accuracy.

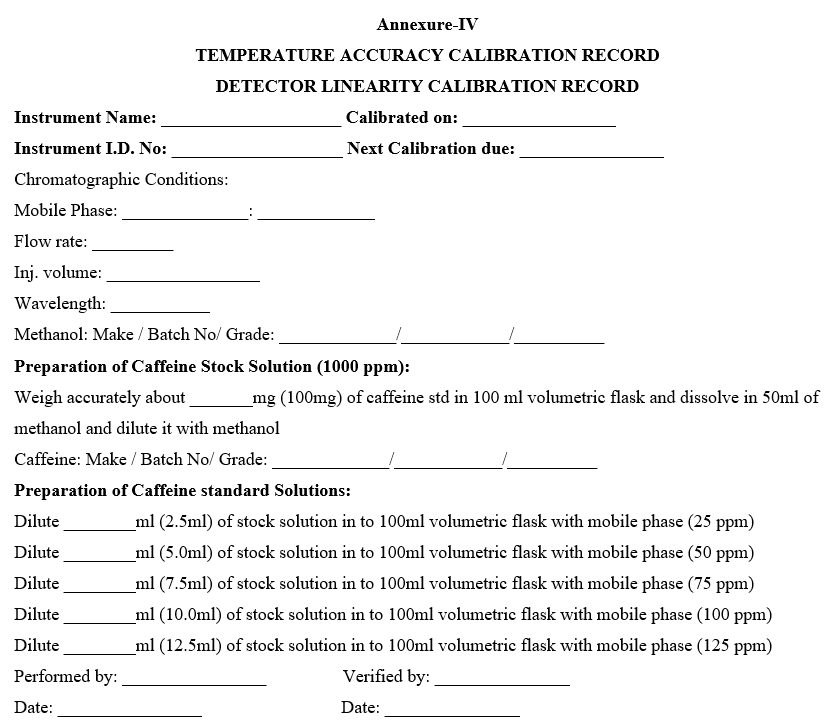

- DETECTOR LINEARITY:

- Fix the Column (Symmetry C18, 4.6mm x 75mm 3.5µm) in the column compartment.

- Prepare the degassed mobile phase mixture of Water and methanol in the ratio of 70: 30, Prepare caffeine working standard solution of 25ppm, 50ppm, 75ppm, 100ppm, and 125ppm concentration from stock solution using mobile phase as diluents.

- Preparation of Caffeine Standard Stock solution (1000ppm): Weigh accurately about 100 mg of caffeine working standard and transfer in to 100 ml volumetric flask dissolve and dilute to volume with methanol.

- Operate the instrument with the following chromatographic conditions:

- Wavelength: 274 nm.

- Flow rate: 1.0 ml / min.

- Injection volume: 10ml.

- Wavelength: 274 nm.

- Flow rate: 1.0 ml/min

- Run time: 4mins.

- Temperature: 25°C.

- Preparation of Caffeine Standard solutions:

- Dilute2.5 ml of stock solution to 100 ml with mobile phase (25ppm).

- Dilute 5.0 ml of stock solution to 100 ml with mobile phase (75ppm)

- Dilute 10.0 ml of stock solution to 100 ml with mobile phase (100ppm).

- Dilute 12.5 ml of stock solution to 100 ml with mobile phase (125ppm)

- Separately inject the above solutions in duplicate and calculate the average peak area response.

- Plot the graph of detector response VS concentration and calculate the detector linearity in terms of correlation coefficient.

- Acceptance criteria:

- The correlation coefficient should be not less than 0.99.Enter the results in calibration record as per Format-IV.

- Calibration schedule: Once in 6 months and after any major maintenance job.

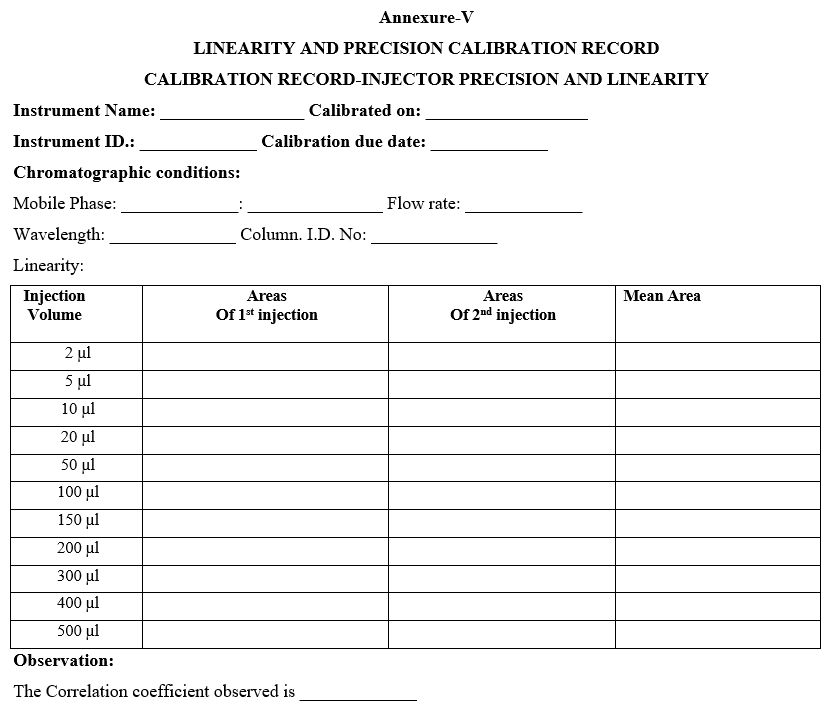

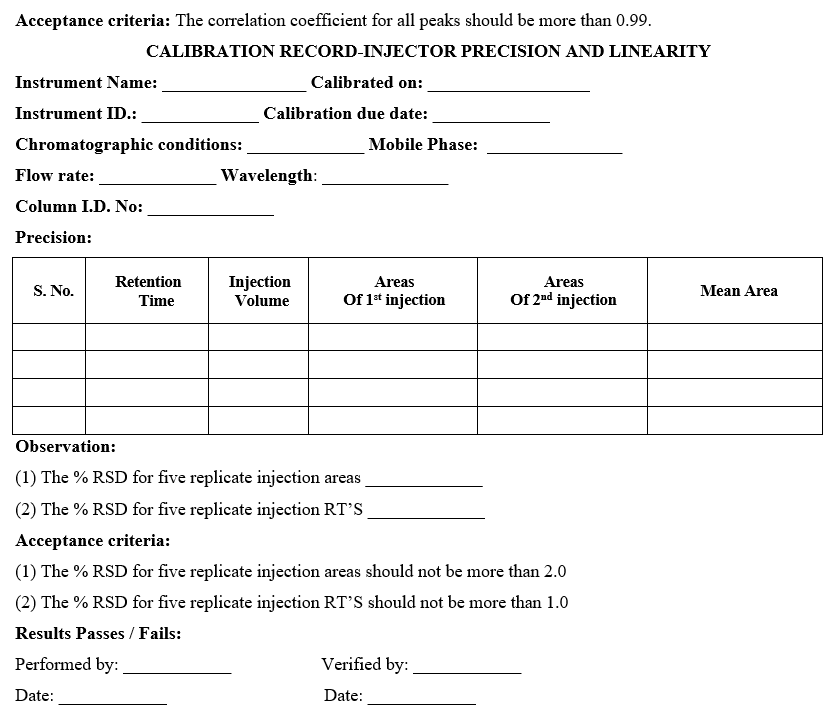

- INJECTOR PRECISION AND LINARITY TEST:

- PRECISION

- Keep mobile phase (Water and methanol in 70:30 ratio) in channel A stabilize for 10 minutes at a flow rate of 1.0 ml/min.

- Fix the column (symmetry C18, 4.6 mm x 75 mm, 3.5µm) in the column compartment.

- Place the 10ppm caffeine solution (Dilute 10 ml of 100ppm caffeine standard solution to 100 ml with mobile phase) sample in carousel.

- Follow the chromatographic conditions for precession.

- Wavelength: 274 nm.

- Flow rate: 1ml/min.

- Injection volume :10µl (For 100 and 200µl loop) 20µl (For 500µl loop)

- Run time: 4 minutes.

- Temperature: 25°C.

- Inject standard solution five times in to the chromatogram and measure the peak area response.

- Acceptance criteria:

- The %RSD area of replicate injections is not more than 2.0 % The %RSD RT of replicate injections is not more than 1.0 %.

- LINEARITY

- Wavelength: 274 nm

- Flow rate: 1 ml /min

- Injection volume:

- For 100µl loop: 2µl, 5µl, 10µl, 20µl, 50µl and 100µl.

- For 200µl loop: 5µl, 10µl, 20µl, 50µl, 100µl, 150µl, 200µl.

- For 500µl loop: 20µl, 50µl, 100µl, 200µl, 300µl, 400µl & 500µl.

- Run time: 4 minutes.

- Temperature: 25°C

- Separately Inject standard solution with above mentioned injection volume in duplicate and measure the average peak area response.

- Plot the graph of detector response VS injection volume and calculate the injector linearity in terms of correlation coefficient.

- Acceptance criteria:

- The correlation coefficient should be not less than 0.99.Enter the results in calibration record as per Format-V.

- Calibration schedule:

- Once in 6 months and after any major maintenance job.

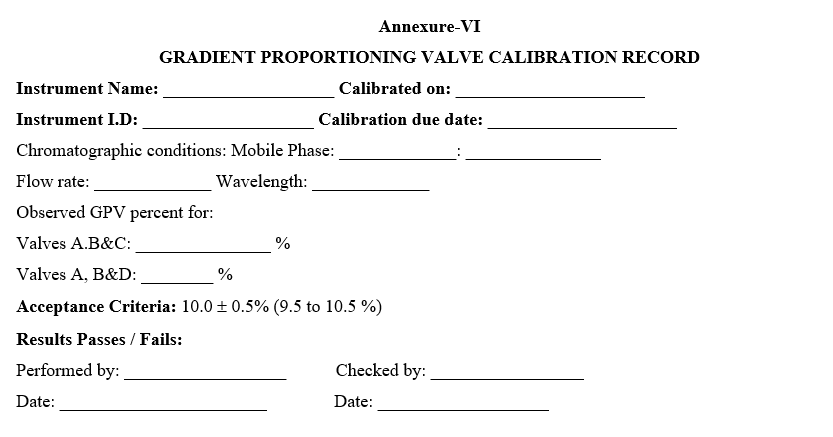

- GRADIENT PROPORTIONING VALVE TEST:

- Preparation For the GPV Test:

- Fill the reservoir for A and B lines with methanol.

- Fill the reservoir for C and D Lines with 500 ml of methanol containing 5.6 mg/L propylparaben / or 1 ampoule of GPV test solution (ref: waters part no WAT042876, per 500 ml solution).

Note: Preparation of 5.6 mg /L propylparaben solution: Take 5.6 mg of propylparaben in1000 ml dry volumetric flask, dissolve and dilute to volume with methanol. Sonicate the solution for 20 minutes.

- Prime the pump.

- Run the inline degasser for 10 minutes.

- Create an instrument method with following parameters.

- Wavelength – 254nm.

- Flow – Gradient (program give below)

- Accept default settings for other parameters.

| Time | Flow | %A | %B | %C | %D | Curve |

| Initial | 2.00 | 50 | 50 | 0.0 | 0.0 | |

| 2.00 | 2.00 | 0.0 | 0.0 | 50.0 | 50.0 | 11 |

| 6.00 | 2.00 | 50 | 50 | 0.0 | 0.0 | 11 |

| 10.00 | 2.00 | 45 | 45 | 10.0 | 0.0 | 11 |

| 12.00 | 2.00 | 50 | 50 | 0.0 | 0.0 | 11 |

| 14.00 | 2.00 | 45 | 45 | 0.0 | 10.0 | 11 |

| 16.00 | 2.00 | 50 | 50 | 0.0 | 0.0 | 11 |

| 18.00 | 0.00 | 50 | 50 | 0.0 | 0.0 | 11 |

- RUN THE GPV TEST:

- Run the sample in single injection mode.

- Run the single injection with 18 minutes run time using the above created method set and prepare and injection icons.

- Select Run only in the Run sample window.

- Acceptance criteria: 10 ± 0.5 %.

- Record all the results in the calibration record as per Format-VI.

Note: Peak height is based on the average height along the flat area at the top of the peak. If not adjust as necessary.

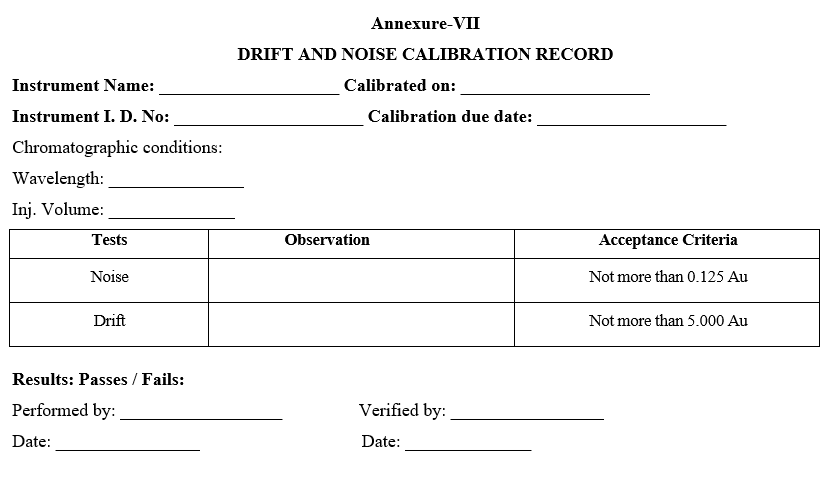

- TEST FOR NOISE AND DRIFT:

- Stop flow from the separations module. Purge the detector flow cell with nitrogen and allow staying for 1 hour.

- Create new instrument method, click on 2690/5 module and select flow as 0.00 ml and accept default settings for all other parameters.

- Click on W2489 detector icon and select wavelength as254 nm.

- Come to single inject, select injection volume 0 µL, vial no.=1 and run time = 60 minutes.

- After the instrument has stabilized, click on prepare for injection icon and after 2 minutes click on inject icon.

- Acceptance criteria: The noise should not be more than 0.125 Au and drift should not be more than 5.000 Au.Enter the results in calibration record as per Format-VII.

- Calibration schedule: Once in 6 months and after any major maintenance job.

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Wavelength accuracy calibration record |

| Annexure-II | Detector Linearity calibration record |

| Annexure-III | Flow Accuracy Calibration record |

| Annexure-IV | Temperature accuracy calibration record |

| Annexure-V | Linearity and precision calibration record |

| Annexure-VI | Gradient proportioning valve calibration record |

| Annexure-VII | Drift and noise calibration record |

Annexure-I

WAVELENGTH ACCURACY CALIBRATION RECORD

Annexure-II

DETECTOR LINEARITY CALIBRATION RECORD

Annexure-III

FLOW ACCURACY CALIBRATION RECORD

Annexure-IV

TEMPERATURE ACCURACY CALIBRATION RECORD

Annexure-V

LINEARITY AND PRECISION CALIBRATION RECORD

Annexure-VI

GRADIENT PROPORTIONING VALVE CALIBRATION RECORD

Annexure-VII

DRIFT AND NOISE CALIBRATION RECORD