- PROCEDURE:

- Layouts shall be prepared for the following but not limited to

- PROCEDURE:

- Layouts shall be prepared for the following but not limited to

- Facility Layout

- Equipment Layout

- Utilities layout (like HVAC, Water System, Compressed Air System)

- Facility Layout includes the following but not limited to

- Site layout

- Different Area/section/ modules

- Man Movement layout.

- Material Movement layout

- Drain Point Location layout.

- Pest and Rodent control layout

- Equipment layout includes the following but not limited to

- Location of equipment in area.

- Schematic arrangement of the equipment

- Utility layout includes the following but not limited to

- Schematic arrangements of AHU, dust collector

- Duct layout, grill layout.

- Pressure Gradient layout, AHU Zoning layout, Area classification layout, P&ID of Water or Compressed Air Systems, AHU Schematic drawing.

- Piping and Instrumentation diagram

- Preparation of layout

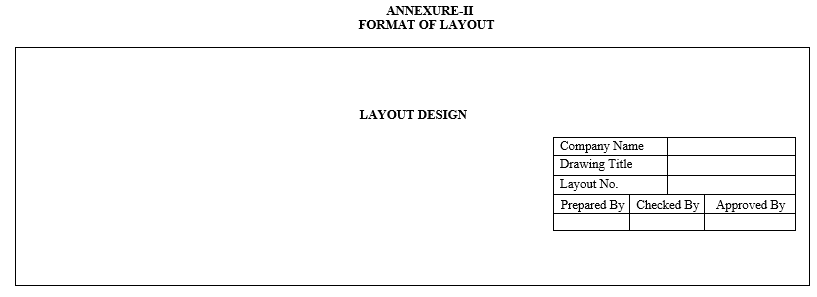

- Engineering / Project department shall prepare the draft copy of layout A3 or A4 as per the format detailed in Annexure-II in consultation with user department layouts depicting only the outline of facility, rooms shall indicate the scale and the units.

- Any short forms, diagrammatic representations, colour codes shall be explained in the layouts.

- Engineering /project department shall put ‘DRAFT COPY’ stamp and shall circulate to the technical/user departments and QA for review.

- Upon receipt of draft copy, the reviewer shall review and send comments to the Engineering/Project department for incorporating the same in the final layout.

- After incorporation of suggestion(s) as applicable, print of layout (QA copy, Display copies as applicable & Site Master File copy as applicable) shall be taken and shall be forwarded for signatures from Technical/User department and final approval from Plant QA In-charge or designee.

- Engineering / Project department shall destroy the draft copy by shredding after the approval of the layout as per Annexure-II

- In case of additional original copy, reprint shall be taken and shall be reviewed by Technical/User department and approved by Plant QA In-charge.

- The layouts prepared by external consultants shall be verified and shall be numbered as detailed in section

- Engineering / Project department shall do the verification and approval.

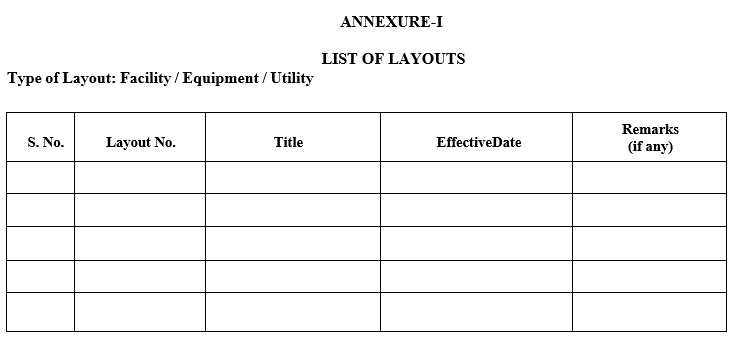

- All approved layouts shall be maintained as per Annexure-I. (List of layouts).

- Issuance of layouts

- Approved layout copies shall be submitted to QA for issuance of the same.

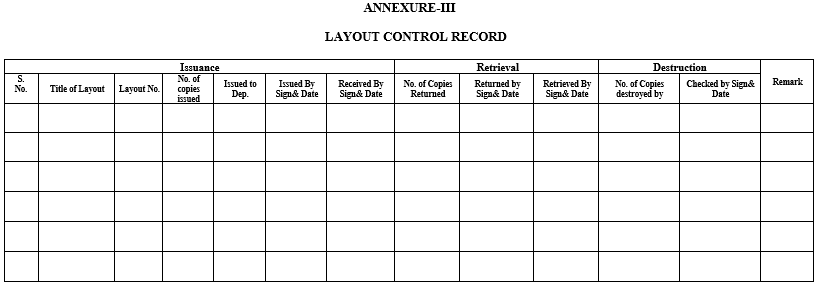

- Documentation person shall enter the layout number and name in the logbook as detailed in Annexure-III.

- User department shall raise document Requisition/Distribution slip, get it approved by Plant QA In-charge or designee.

- QA shall issue the Photocopy of the layout as a DISPLAY copy and shall take the Signature of the receiver in the logbook.

- In case, the layout is required to be issued to external agencies, regulatory bodies, customers, additional original copy, reprint shall be taken and shall be reviewed by Technical/User department and approved by Plant QA In-charge or Photocopy of QA copy or SMF copy shall be taken and issued with stamp Reference copy – Not for operational use.

- Revision of Layouts

- The existing layout, if revised, due to any changes/modification in the facility or system or equipment location, then Initiator department shall raise the change control with necessary justification.

- After approval of the Change Control, Layout shall be revised, and the changes shall be recorded in the change history as per Annexure-IV.

- All the existing controlled copies of layout shall be retrieved and forwarded to QA by concerned department(s).

- Upon receipt of the retrieved copy, QA shall record and destroy the retrieved copy (ies) by shredding and maintain the record for the same.

- QA copy of the layout shall be maintained by putting the stamp “OBSOLETE” in red on the layout and filed separately.

- Plant QA shall control, issue, and retrieve the layouts and maintain records.

- Numbering of layouts

- A unique number shall be assigned for layouts.

- AAA/BBB/C/NNN-XX

- AAA: Indicates Company name abbreviations.

- BBB: Indicate Layout

- C: Indicates for if facility layout the Facility Layout denotes as “F” , `E` for Equipment layout `U` for Utility layout

- NNN: Indicates serial no of layout start from 001,002, 003……

- XX: Indicates version number of layout starting from 00 and continuing serially in increments of one unit.

- For e.g. the facility layout no shall be given as AAA/LYT/F/001-00

- There shall be separate series for each type of layout i.e. Facility, Equipment and Utility.

- REFERENCES:

- Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | List of Layouts |

| Annexure-II | Format of Layout |

| Annexure-III | Layout Control Record |

| Annexure-IV | Change History Sheet |

- ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

- P&I : Piping and Instrumentation

- HVAC : Heating Ventilation and Air-conditioning

- AHU : Air Handling Unit

- QA : Quality Assurance

- REVISION HISTORY:

- CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

Annexure-I

LIST OF LAYOUTS

Annexure-II

FORMAT OF LAYOUT

Annexure-III

LAYOUT CONTROL RECORD

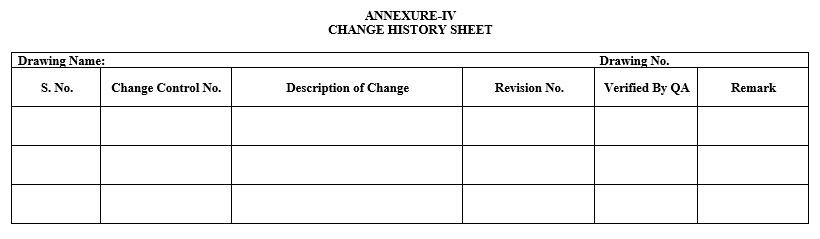

Annexure-IV

CHANGE HISTORY SHEET