- PROCEDURE:

- MAKE: CAMAG

- Preliminary operational instructions for Linomat 5:

- Check that the cable, electrical connection and connection of gas line are proper before Switching on the instrument.

- Switch on the Linomat 5. Open the valve of the gas cylinder and adjust the pressure to 58-87 psi.

- Check the turret is at perpendicular to the stage (TLC plate table), move it if necessary.Switch on the main and instrument.

- Procedure of spotting on Linomat 5:

- Make sure that plate stage is in front position and the syringe lever arm is at the top of the turret.

- Carefully insert the syringe through the syringe holder into the spray ahead and lower the syringe carefully until it rests in the spray head.

Note: The volume of the syringe in use must be set in the user dialog. If a wrong syringe volume is entered, the application volumes will all be wrong.

- Insert a waste TLC plate beside the stage, just below the syringe position.

- Place the TLC plate on the stage in a proper position and secure it with magnetic strips.

- Create the new method using following parameters:

- Analysis: Select the sample application as ‘Linomat- 5’ and development as ‘Chamber’ and rest of the parameters will be as default ones.

- Stationary phase: Details like plate size, material name, manufacturer, Batch Number etc. will be entered.

- Sample application:

- Linomat 5 General: Application volume should be the syringe capacity

- Sequence: Select the syringe size (Either 100µl (or) 500µl), Number of tracks and band length.

- While creating the sequence if different application volumes are required apply the same and change the position of spotting if required using number of tracks if required.

- After entering all required fields save the method.

- After creation of method take the method printout before executing to next step.

- When the system is ready for spotting ‘Execute next step’ command has to be given.

- When the analysis is completed, switch off the power supply, turn off the valves of the gas supply, remove the TLC plate, and clean the sample dosage syringe.

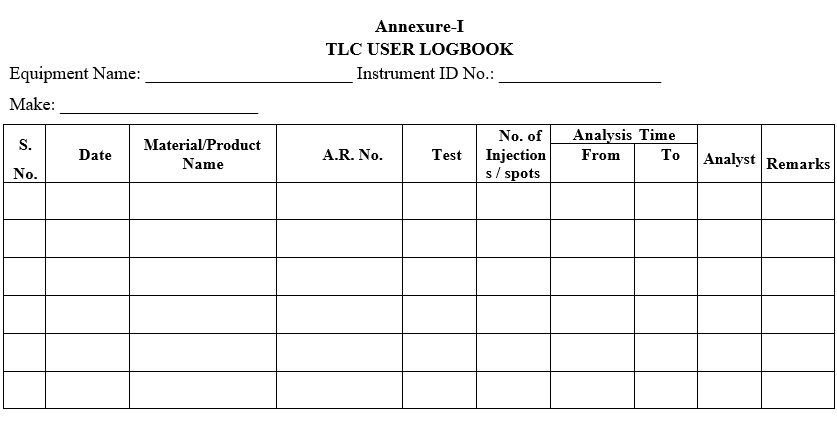

- After using the instrument make the logbook entry as per format-I.

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | TLC User logbook |

Annexure-I

TLC USER LOGBOOK