- OBJECTIVE:

- To lay down a procedure for operation of vertical autoclave, Make: Equitron.

- SCOPE:

- This SOP is applicable to the procedure for operation of vertical autoclave, Make: Equitron at {Company Name} {Location}.

- RESPONSIBILITY:

- Officer/Executive/Designee (QC) Micro. – Shall be responsible to follow the procedure as per SOP.

- Head/Designee Quality Control – Shall be responsible for ensuring compliance as per SOP.

- ACCOUNTABILITY:

- QA Head shall be Accountable for implementation of SOP.

- OPERATING PROCEDURE OF VERTICAL AUTOCLAVE:

- Make: Equitron

- VERTICAL AUTOCLAVE: A vertical autoclave, also known as a top-loading autoclave or steam sterilizer, is a cylindrical chamber used for sterilization by steam under pressure.

- PROCEDURE FOR AUTO OPERATION: Before operating the autoclave ensure sufficient water level.

- To open the lid, press the RELEASE LEVER downwards and then raise the MAIN LEVER till the RELEASE LEVER latches back at its upper position.

- Move the lid using lid handle to use sterilizing chamber.

- To close the lid, press the RELEASE LEVER downwards and then press the MAIN LEVER to downwards.

- Ensure that the drain valve at the bottom of the autoclave should be closed.

- Pour purified water directly into the autoclave up to the heater cover stand. (Do not pour water on water level float switch).

- Place the discarded items into the baskets, close the lid and tighten the knobs fully without allowing any space for steam leakage.

- Open the graph recorder’s door and place a graph into the graph recorder.

- Switch on the button present in the graph recorder as it glows indicates readiness to record the graph. When power switched ON the display will show the status as “EQUITRON Autoclave” for few seconds and then the main screen will appear as process temperature and set time (in bracket).

- To set the required temperature press “MENU” button, the display will change by Pressing “UP” or “DOWN” arrow keys and press ENTER, the display will go to Timer mode.

- Next change the time by pressing “UP” or “DOWN” arrow keys and press ENTER, the display will return to the main screen.

- Press START / STOP key to start the cycle. (In case of problems encountered, the buzzer will sound, and the problem will be on the display.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-vertical-autoclave/

- At any process stage to stop cycle press STSRT / STOP key again).

- The solenoid valve will remain open up till the temperature reaches approximately 99-100 °C in order to purge the stale air enclosed in the autoclave, after which it will automatically close.

- After this, the temperature and pressure will gradually rise, which will be indicated by the microprocessor and pressure gauze respectively.

- The timer will start count down after the set temperature is attained.

- During the countdown the temperature and the pressure will be maintained by the microprocessor controller by switching ON / OFF the heater. (During this countdown period safety valve may leak slightly)

- After the elapse of the set time, a buzzer will sound for 20 seconds, the heaters will be cut OFF and the solenoid valve opens to exhaust the pressure.

- Switch OFF the autoclave and wait till the pressure gauze reading reaches to ZERO, before opening the autoclave. Remove the graph from the graph recorder and write the date, time, lot number and sign of the performer.

- Unload the items from stainless steel basket placed over the stand and discard.

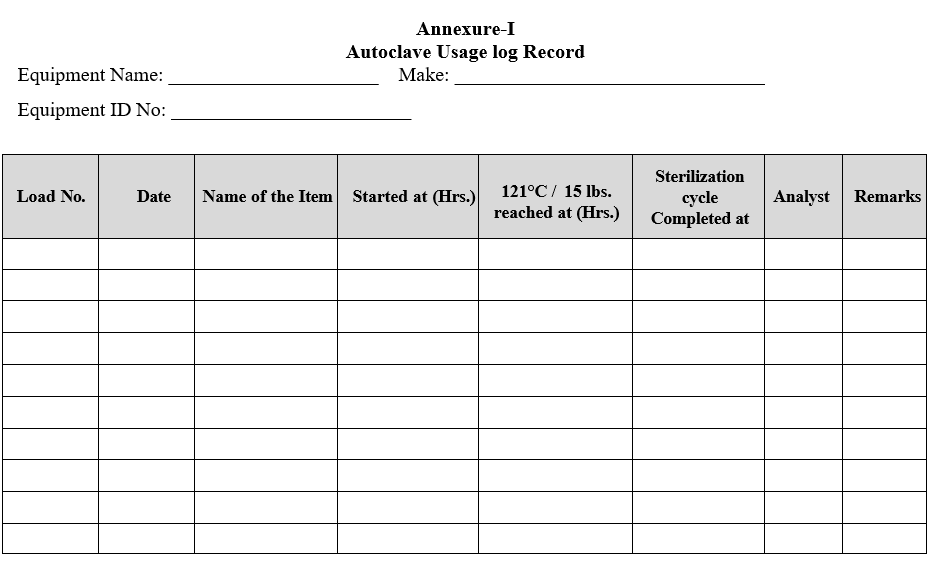

- Record the details of the load as per Format-I.

NOTE: Maintain the Autoclave at 15 / lbs for 30 minutes to destroy the contaminated media. NOTE: In case of micro controller failure the machine can also be run in manual mode.

- PROCEDURE FOR MANUAL OPERATION:

- Switch off the MCB of the autoclave.

- Rotate over the rotary switch to position 2 (Manual mode).

- Fit a safety valve along with nozzle (provide with autoclave) which is set at 15 psi in the QRC provided on lid of the autoclave.

- Switch on the MCB. Now the heater will operate continuously.

- At 15 psi safety valve at QRC will open and maintain the pressure.

- Please start the timer as soon as the cycle reaches 15 psi.

- After elapse of desire hold time, switch off the MCB and release the chamber pressure using manual exhaust valve provided on the lid.

- ANNEXURES:

| Annexure No. | Title of annexure |

| Annexure-I | Autoclave Usage log Record |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head QC (Micro.)

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Recorded Manual |

Annexure-I

Autoclave Usage log Record

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-vertical-autoclave/