- OBJECTIVE:

- To lay down a procedure for operation of laminar airflow.

- SCOPE:

- This SOP is applicable to the procedure for operation of laminar airflow at {Company Name} {Location}.

- RESPONSIBILITY:

- Officer/Executive/Designee (QC) Micro. – Shall be responsible to follow the procedure as per SOP.

- Head/Designee Quality Control – Shall be responsible for ensuring compliance as per SOP.

- ACCOUNTABILITY:

- QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

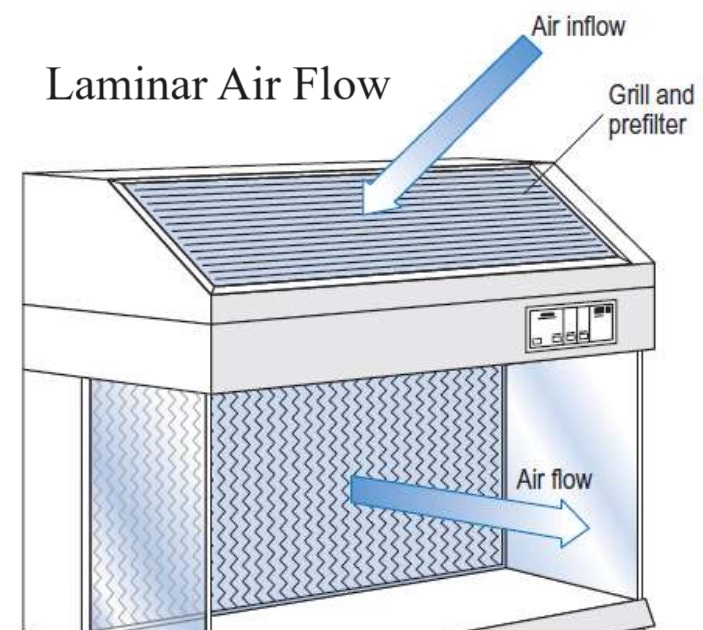

- Laminar air flow: Laminar air flow (LAF) is a type of air flow that is smooth, uniform, and in a single direction. It’s achieved by drawing air through a HEPA filter, which removes particles as small as 0.3 microns, and then blowing it evenly across a workspace. This creates a clean and controlled environment that is ideal for work that requires minimal contamination.

- Check the level of instrument base. The base should possess a uniform level with no up and downs.

- Ensure that the laminar airflow station is free from dust and placed in such a position that no turbulence is created while opening the door.

- Switch ON the mains.There are six switches at the left side or front side panel of the equipment and a magnehelic gauge at the centre or right side corner.

- Switch (1&2) for air Flow – LAF – ‘ON’ & ‘OFF’Switch (3&4) for light – ‘LUX’ – ‘ON’ & ‘OFF’Switch (5&6) for UV light – ‘UV’ – ‘ON’ & ‘OFF’

- The Air Flow and UV should be kept ON for about 30 minutes before carrying out any work under laminar airflow.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-laminar-air-flow/

- Switch ‘OFF’ the UV and put ‘ON’ the normal light.

- Check the magnehelic gauge reading and ensure that it is at zero before the LAF unit is switched ON.

- Ensure that the magnehelic gauge reading is in between 10 -25 mm.

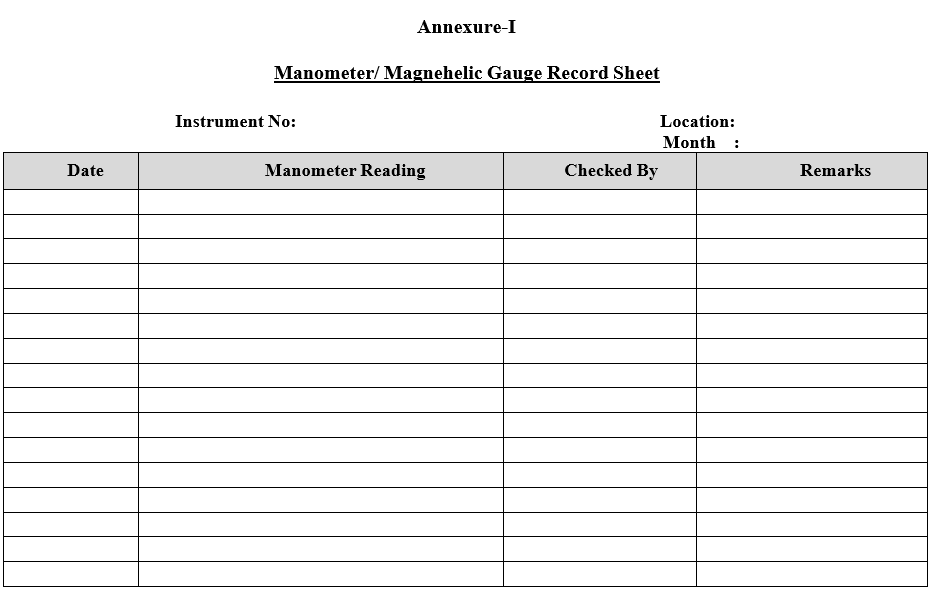

- Maintain a record of the manometer readings daily as per Format-I.

- Switch ‘OFF’ the LAF after the completion of the test.

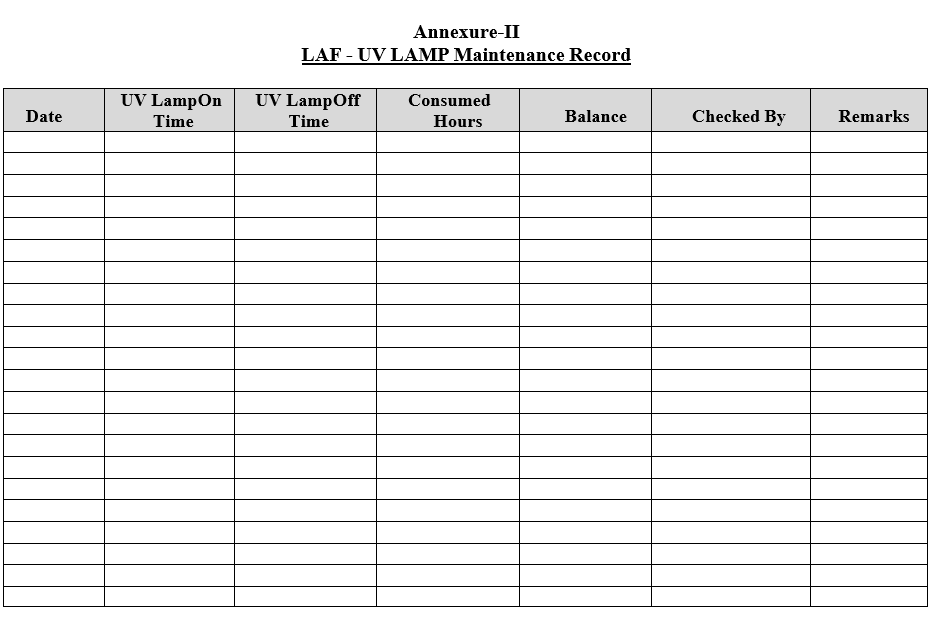

- Maintain a separate record for UV lamp burning hours (usually 2000hrs) as per Format-II.

- ANNEXURES:

| Annexure No. | Title of annexure |

| Annexure-I | Manometer /Maghnaulic gauge Readings Record |

| Annexure-II | LAF UV Lamp Maintenance Record. |

- DISTRIBUTION:

Master Copy : Quality Assurance Department

Controlled Copy No. 01 : Head Quality Assurance

Controlled Copy No. 02 : Head QC (Micro.)

- ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

Manometer/ Magnehelic Gauge Record Sheet

Annexure-II

LAF – UV LAMP Maintenance Record

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-laminar-air-flow/