OBJECTIVE:

To lay down a procedure for Bowie dick test.

SCOPE:

This SOP is applicable for Bowie Dick test in pharmaceutical plant.

RESPONSIBILITY:

Technical Assistant –Production shall follow the procedure mentioned in SOP.

Executive – Production shall ensure the compliance as per SOP.

ACCOUNTABILITY:

Production Head

Head Quality Assurance

PROCEDURE:

The Bowie & Dick test enables you to ensure that air is properly removed from the sterilization chamber and, as a result, that porous loads are fully penetrated with steam.

Procedure and operation:

The indicator is a heat-sensitive sheet placed in the middle of a pack consisting of several layers of paper and foam.

This sheet changes colour when exposed to a certain level of pressure from the saturated steam.

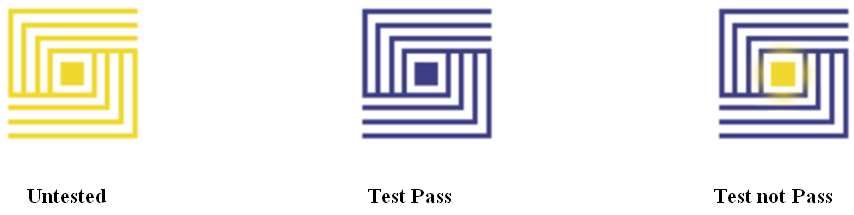

For the autoclave to be working efficiently, it must be able to evenly sterilise the porous pack. When this is the case, the pack will be evenly penetrated and the Bowie-Dick test sheet will be uniform in colour, without different-colour stains.

The required resulting colour depends on the manufacturer and will be detailed in the manufacturer’s instructions.

The test must be carried out in the following way:

The vacuum test is performed.

Take the Bowie & Dick test pack, which must be the only thing in the autoclave and place it in the middle of the lower shelf in the sterilization chamber (if these conditions are applied, the amount of air to be removed is greater and the test is more discerning). The test pack has a sheet of paper inside with special ink (chemical indicator) applied to it, which will change colour evenly from the outer edges to the middle.

The appropriate programme to carry out the Bowie & Dick Test is then selected and started on the autoclave (the program will perform a complete sterilization cycle at 134 °C and 2.1 atm. for 3 minutes and 30 seconds).

Then examine the sheet to see whether or not the colour has changed evenly, and with the same intensity, from the middle to the outer edges. Then compare the result obtained with the supporting examples.

If the test fails, it means that the sterilization system is inefficient due to a number of possible reasons:

Poor-quality steam emitted by the sterilization machine;

Failure to create a vacuum with air being present;

A leak during air removal (initial vacuum phase).

Note: If the result is a failure, the Bowie & Dick test is repeated: if this test is successful, a third confirmatory test is carried out.

Operation of Autoclave:

Switch ON the machine with the key.

- Ensure that autoclave chamber is dry and temperature is ambient.

- Check the cleaning of chamber and all around the machine.

- Check the availability of soft water, pure steam, plant steam and compressed air.

- Check the pressure of compressed air should not be less than 6.0 kg/cm².

- Open the valve of plant steam supply line and ensure that the pressure of plant steam supplied to the autoclave in the pressure gauge is not less than 2 kg/cm².

- Open the valve on pure steam supply line and ensure that the pressure of pure steam supplied to the autoclave in the pressure gauge is Not Less Than 2 kg/cm².

- Load the Bowie Dick test kit in the Bung processor cum Steam Sterilizer (Keep the kit at 200mm from the bottom of chamber) as per validated loading pattern.

- Press the “door close switch” to close the door.

- Check the pressure of following mentioned below on front of the panel :-

- Jacket Pressure : 0.0 Kg/cm²

- Sterile side gasket : 3.0 Kg/cm²

- Non sterile gasket : 3.0 Kg/cm²

- Chamber pressure : 0.0 Kg/ cm²

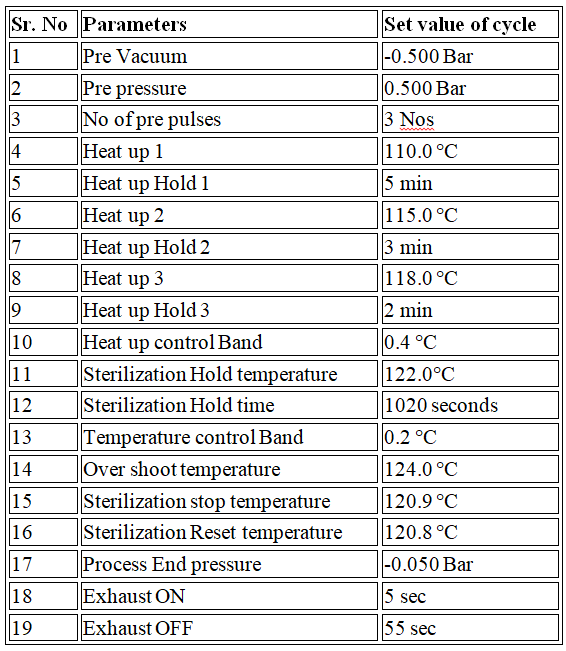

Select the Cycle No. on the MMI of the Bung processor cum Steam Sterilizer. Check and verify the standard parameter of bowie dick test on man machine interface (MMI) as per mentioned below:

Set Parameter:

On completion of the sterilization according to the set parameter, indicator of “process end” will glow on sterile side door and the process will stop, displaying the message ‘Process End’ on MMI.

Check the cycle graph for Bowie Dick test load for temperature and time during the sterilization hold.

Check the uniform color of Bowie dick paper is dark brown after the cycle.

If the graph does not match the cycle will be considered invalid. Repeat the Bowie Dick test. Inform the deviation to the Quality Assurance Department. Carry out the further processing as per the suggestions from the quality assurance.

Record the cycle details of Operation in the Equipment Logbook as per SOP and get it checked by the Concerned Supervisor / Officer.

REFERENCES:

Not Applicable

ANNEXURES:

Not Applicable

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

Controlled Copy No. 01 Head Quality Assurance

Controlled Copy No. 02 Head-Production

Master Copy Quality Assurance Department

ABBREVIATIONS:

SOP : Standard Operating Procedure

MMI : Man Machine Interface

PLC : Programmable Logic Controller

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |