OBJECTIVE:

To lay down a procedure forSampling and Testing of Packing Material.

SCOPE:

This SOP is applicable for Sampling and Testing of Packing Material of Quality Control Department at {Company Name} {Location}.

RESPONSIBILITY:

All entrants – To follow the instruction as per SOP

QC Head – Review, technical correction, training and monitoring of SOP.

QA Head – Approval and implementation of SOP.

- ACCOUNTABILITY:

QA Head shall be accountable for implementation of SOP.

PROCEDURE:

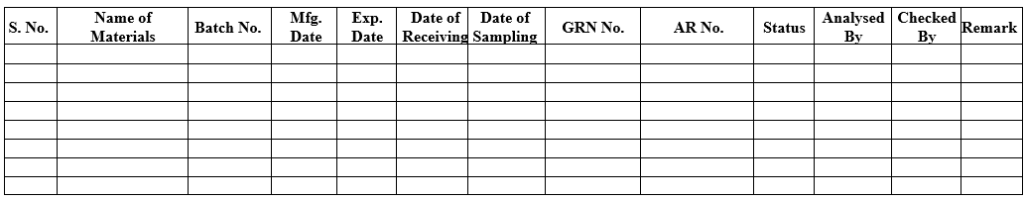

- QC Officer shall maintain all details in packing material inward register from GRN as per Annexure-IV

- QC Officer shall plan the sampling activity accordingly and QC Executive shall issue the under test and sampled labels to QC Officer.

- QC Officer shall inform to packing material store department about sampling.

- Take 100% sample for primary packing material.

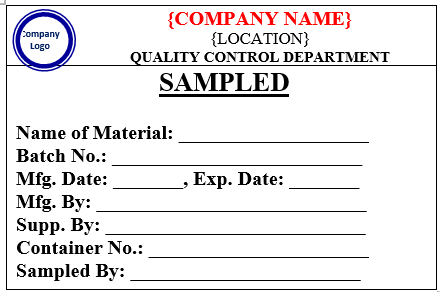

- QC Officer shall verify the GRN details against the detail mentioned n containers/ packs and record the observations in packing material inspection report as per Annexure-III

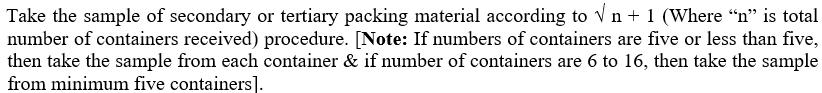

- QC Officer shall take the sample quantity as per respective specification as per Annexure-II

- Analysis (Physical parameter) of tertiary packing material shall be performed with 5 samples from each consignment in store and only one sample shall be carried out in QC for other tests.

- Take the sample of primary packing material under LAF.

- Check the pressure differential of LAF (if applicable).

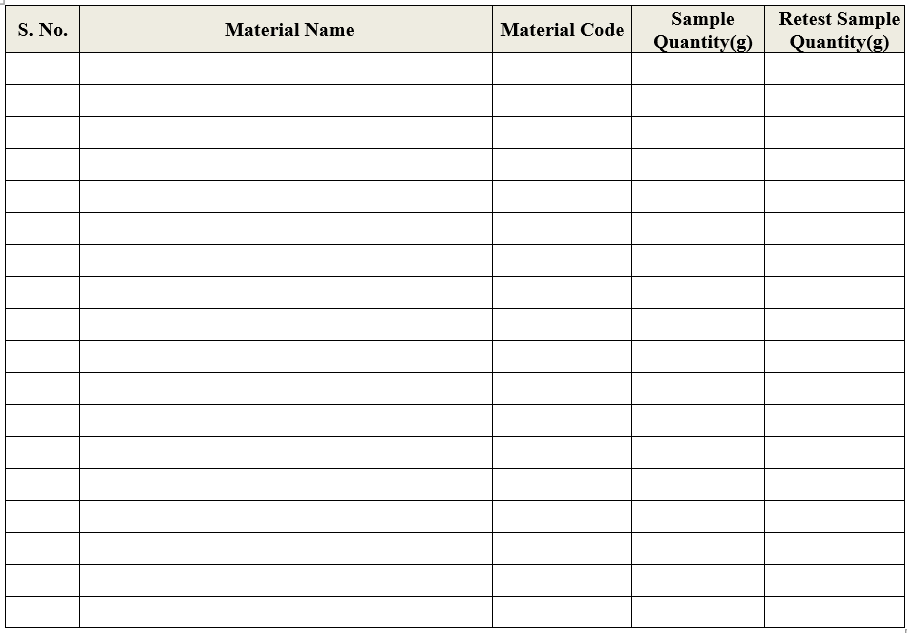

- Affix a label ‘SAMPLED’ to identify the container/packs from which the sample is drawnas per Annexure-I

- Affix the label ‘UNDER TEST’ to the container/pack.

- After collecting the sample from store, QC Officer shall sign with date in sampled by/date column in packing material inward register.

REFERENCES:

Not Applicable

ANNEXURES:

| ANNEXURE | NAME OF ANNEXURE |

| Annexure-I | List of pack materials sample quantity for analysis |

| Annexure-II | Sampled Label |

| Annexure-III | Packing Material Inspection Report |

| Annexure-IV | Packing Material Inward Register |

DISTRIBUTION:

| Controlled Copy No. 01 | : | Manager Quality Assurance |

| Controlled Copy No. 02 | : | Manager Quality Control |

| Master Copy | : | Quality Assurance Department |

ABBREVIATIONS:

| SOP | : | Standard Operating Procedure |

| No. | : | Number |

| QC | : | Quality Control |

| GRN | : | Good Receipt Note |

| LAF | : | Laminar Air Flow |

| CFR | : | Code of Federal Regulation |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable |

ANNEXURE-I

LIST OF PACK MATERIALS SAMPLE QUANTITY FOR ANALYSIS

ANNEXURE-II

SAMPLED LABEL

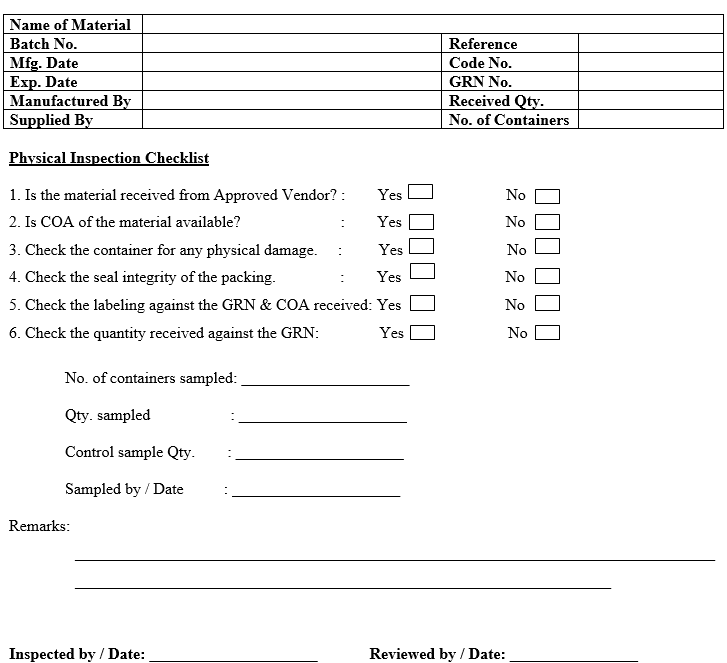

ANNEXURE-III

PACKING MATERIAL INSPECTION REPORT

ANNEXURE- IV

PACKING MATERIAL INWARD REGISTER