OBJECTIVE:

To lay down a Procedure for Status Labeling.

SCOPE:

This SOP is applicable for Status Labeling during various Operations of Production, QC, QA, Warehouse & Engineering at {Company Name} {Company Location}.

RESPONSIBILITY:

Production, Warehouse, QA, Engineering and QC Officer / Executive.

ACCOUNTABILITY:

Head of all departments.

PROCEDURE:

Status Labeling is a stage where different types of Labels are affixed at various stages of Operations on In Process Containers, Samples, Areas, and Equipments / Instruments. Different Color code is given to various Labels for proper identification.

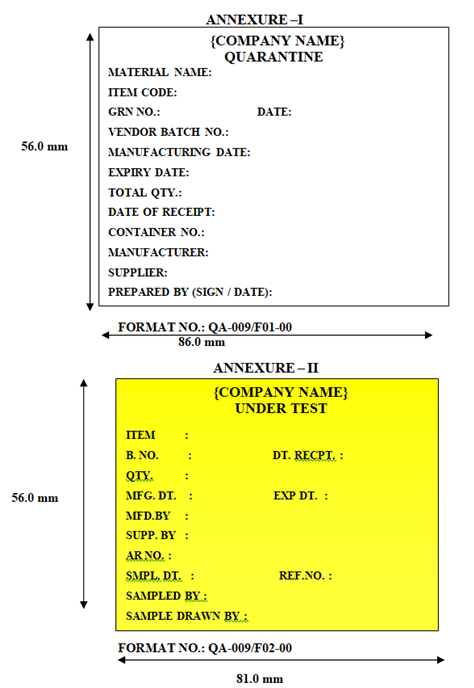

- “QUARANTINE” LABEL:

- ‘QUARANTINE’ Label shall be affixed on the received Raw and Packaging Material in Warehouse by Warehouse person.

- Specification of Label shall be 86.0 mm (L) X 56.0 mm (H).

- Quarantine Label shall contain White Color background with text in Black.

- Specimen of ‘QUARANTINE’ Label is as shown in Annexure-I.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| QUARANTINE | 11 Font Capital & Bold |

| MATERIAL NAME | 9 Font Capital & Bold |

| ITEM CODE | 9 Font Capital & Bold |

| GRN NO. | 9 Font Capital & Bold |

| DATE | 9 Font Capital & Bold |

| VENDOR BATCH NO. | 9 Font Capital & Bold |

| MANUFACTURING DATE | 9 Font Capital & Bold |

| EXPIRY DATE | 9 Font Capital & Bold |

| TOTAL QTY. | 9 Font Capital & Bold |

| DATE OF RECEIPT | 9 Font Capital & Bold |

| CONTAINER NO. | 9 Font Capital & Bold |

| MANUFACTURER | 9 Font Capital & Bold |

| SUPPLIER | 9 Font Capital & Bold |

| PREPARED BY (SIGN. / DATE) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- “UNDER TEST” LABEL:

- After sampling from the consignment QC Officer shall sample and affix ‘UNDER TEST’ Labelon the ‘QUARANTINE LABEL’, by overlapping the part where ‘QUARANTINE’ word is written.

- Specification of the Label shall be 81.0 mm (L) X 56.0 mm (H).

- Under Test Label shall contain Yellow Color background with text in Black.

Click the link to download the complete procedure:

https://pharmaguidehub.com/product/status-labeling/

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| UNDER TEST | 11 Font Capital & Bold |

| ITEM | 9 Font Capital & Bold |

| B. NO. | 9 Font Capital & Bold |

| DT. RECPT. | 9 Font Capital & Bold |

| QTY. | 9 Font Capital & Bold |

| MFG. DT. | 9 Font Capital & Bold |

| EXP. DT. | 9 Font Capital & Bold |

| MFD. BY. | 9 Font Capital & Bold |

| SUPP. BY | 9 Font Capital & Bold |

| AR NO. | 9 Font Capital & Bold |

| SMPL. DT. | 9 Font Capital & Bold |

| REF.NO. | 9 Font Capital & Bold |

| SAMPLED BY | 9 Font Capital & Bold |

| SAMPLE DRAWN BY | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- Specimen of ‘UNDER TEST’ Label is as shown in Annexure-II.

- “Q.C.APPROVED” LABEL:

- ‘Q.C. APPROVED’ Label shall be affixed on theRaw and Packaging Material approved by QC, by overlapping the Under Test Label.

- Specification of the Label shall be 86.0 mm (L) X 56.0 mm (H).

- Approved Label shall contain Green Color Background with text in Black Color.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| Q.C. APPROVED | 11 Font Capital & Bold |

| ITEM NAME | 9 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| MFG.DT. | 9 Font Capital & Bold |

| EXP. DT. | 9 Font Capital & Bold |

| QTY. RECVD. | 9 Font Capital & Bold |

| A.R.NO. | 9 Font Capital & Bold |

| LOD | 9 Font Capital & Bold |

| ASSAY | 9 Font Capital & Bold |

| RELEASE DATE | 9 Font Capital & Bold |

| RE TESTING DATE | 9 Font Capital & Bold |

| RELEASED BY | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- Specimen of ‘Q.C.APPROVED’ Label is as shown in Annexure-III.

- “REJECTED” LABEL:

- ‘REJECTED’ Label shall be affixed on theRaw and Packaging Material Rejected by QC.

- Specification of the Label shall be 89.0 mm (L) X 56.0 mm (H).

- Rejected Label shall contain Red Color background with text in Black Color.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| REJECTED | 11 Font Capital & Bold |

| ITEM | 9 Font Capital & Bold |

| B. NO. | 9 Font Capital & Bold |

| MFG. DT. | 9 Font Capital & Bold |

| EXP. DT. | 9 Font Capital & Bold |

| QTY. | 9 Font Capital & Bold |

| NO. OF PKG. | 9 Font Capital & Bold |

| MFD. BY | 9 Font Capital & Bold |

| SUPP. BY | 9 Font Capital & Bold |

| A.R. NO. | 9 Font Capital & Bold |

| DATE | 9 Font Capital & Bold |

| STORE I/C | 9 Font Capital & Bold |

| Q.A. OFFICER | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- Specimen of ‘REJECTED’ Label is as shown in Annexure-IV.

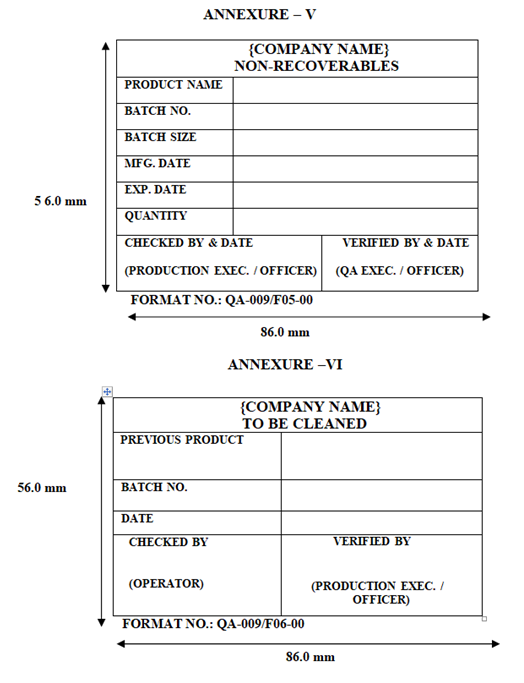

- “NON-RECOVERABLES” LABEL:

- NON-RECOVERABLES’ Status Label shall be affixed on the container which contain materials generated during Manufacturing and Packing activities and cannot be reuse. For Example: Broken & Sealing Rejected Container/Jar after filling & sealing operation, Broken Jar/Container (After Filled Jar/Container Inspection), Rejection generated during Semi-finished / Packing stage etc.

- Non-Recoverables Label shall contain White Color background and text in Black Color.

- Non-Recoverables Status Label shall be filled by Production Executive / Officer and cross verified by QA Executive / Officer and shall be signed along with Date.

- Specification of the Label shall be 86.0 mm (L) × 56.0 mm (H).

Click the link to download the complete procedure:

https://pharmaguidehub.com/product/status-labeling/

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| NON-RECOVERABLES | 11 Font Capital & Bold |

| PRODUCT NAME | 9 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| BATCH SIZE | 9 Font Capital & Bold |

| MFG. DATE | 9 Font Capital & Bold |

| EXP. DATE | 9 Font Capital & Bold |

| QUANTITY | 9 Font Capital & Bold |

| CHECKED BY & DATE (PRODUCTION EXEC./ OFFICER) | 9 Font Capital & Bold |

| VERIFIED BY & DATE (QA EXEC. / OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Normal & Capital |

- Specimen of ‘NON-RECOVERABLES’ Label is as shown in Annexure-V.

- “TO BE CLEANED” LABEL:

- ‘TO BE CLEANED’ Label shall be affixed on the IP Containers, Equipments, Utensils, Machines and areas which are to be cleaned.

To be Cleaned Label shall contain White Color background with text in Black Color.

- To Be Cleaned Status Label shall be filled by Operator and verified by Production Executive / Officer, and shall be signed along with Date.

- Specification of the Label to Be Cleanedshall be 86.0 mm (L) × 56.0 mm (H).

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| TO BE CLEANED | 11 Font Capital & Bold |

| PREVIOUS PRODUCT | 9 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| DATE | 9 Font Capital & Bold |

| CHECKED BY (OPERATOR) | 9 Font Capital & Bold |

| VERIFIED BY (PRODUCTION EXEC. / OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- Specimen of ‘TO BE CLEANED’ Label is as shown in Annexure-VI.

- “INPROCESS STATUS” LABEL:

- ‘INPROCESS STATUS’ Label shall be affixed on the Containers / Equipment which contains Semi- Finished or Finished Materials during operations.

- In process Status Label shall contain White Color backgroundwith textin Black Color.

- In process Status Label shall be filled by Production Executive / Officer and cross verified by QA Executive / Officer and shall be signed along with Date.

- Specification of the in process Status Label shall be 86.0 mm (L) × 56.0 mm (H).

- Specimen of ‘INPROCESS STATUS’ Label is as shown in Annexure-VII.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| INPROCESS STATUS | 11 Font Capita & Bold |

| PRODUCT NAME | 9 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| BATCH SIZE | 9 Font Capital & Bold |

| MFG. DATE | 9 Font Capital & Bold |

| EXP. DATE | 9 Font Capital & Bold |

| STAGE | 9 Font Capital & Bold |

| CHECKED BY & DATE (PRODUCTION EXEC. / OFFICER) | 9 Font Capital & Bold |

| VERIFIED BY & DATE (QA EXEC./ OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- STATUS LABEL:

- ‘STATUS LABEL’ shall be affixed for showing the status of Equipments, IPCs, Machines, Materials Status and Rooms / Areas status etc.

- Status Label shall contain White Color background with text in Black Color.

- Specification of Status Label shall be 86.0 mm (L) × 56.0 mm (H).

- Specimen of ‘STATUS LABEL’ is as shown in Annexure-VIII.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| STATUS LABEL | 11 Font Capital & Bold |

| PRODUCT NAME | 9 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| BATCH SIZE | 9 Font Capital & Bold |

| MFG. DATE | 9 Font Capital & Bold |

| EXP. DATE | 9 Font Capital & Bold |

| STAGE | 9 Font Capital & Bold |

| CHECKED BY & DATE (PRODUCTION EXEC./ OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

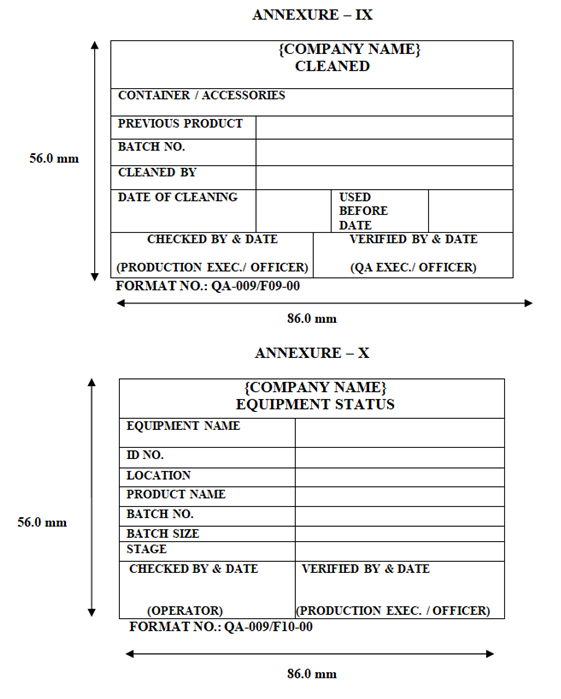

- “CLEANED” LABEL:

- CLEANED’ Status Label shall be affixed on the Containers, Equipments, Utensils, Machines, IPCs and Areas to indicate status of cleaning.

- Status Label shall contain White Color background with text in Black Color.

- Cleaned Label shall be checked by production Executive / Officer and verified by QA Executive / Officer and shall be signed along with Date.

- Specification of CleanedStatus Label shall be 86.0 mm (L) X 56.0 mm (H).

- Specimen of ‘CLEANED’ Label is as shown in Annexure-IX.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| CLEANED | 11 Font Capital & Bold |

| CONTAINER / ACCESSORIES | 9 Font Capital & Bold |

| PREVIOUS PRODUCT | 9 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| CLEANED BY | 9 Font Capital & Bold |

| DATE OF CLEANING | 9 Font Capital & Bold |

| USED BEFORE DATE | 9 Font Capital & Bold |

| CHECKED BY & DATE (PRODUCTION EXEC./ OFFICER) | 9 Font Capital & Bold |

| VERIFIED BY & DATE (QA EXEC./ OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- “EQUIPMENT STATUS” LABEL:

- EQUIPMENT STATUS’ Label shall be affixed on the machine during operation time of the machine to indicate the stage of product.

- Status Label shall contain White Color background with text in Black Color.

- Equipment Status Label shall be filled by operator and verified by Production Executive / Officer and shall be signed along with Date.

- Specification of Equipment Status Label shall be 86.0 mm (L) × 56.0 mm (H).

- Specimen of ‘EQUIPMENT STATUS’ Label is as shown in Annexure-X.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| EQUIPMENT STATUS | 11 Font Capital & Bold |

| EQUIPMENT NAME | 9 Font Capital & Bold |

| ID NO. | 9 Font Capital & Bold |

| LOCATION | 9 Font Capital & Bold |

| PRODUCT NAME | 9 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| BATCH SIZE | 9 Font Capital & Bold |

| STAGE | 9 Font Capital & Bold |

| CHECKED BY & DATE (OPERATOR) | 9 Font Capital & Bold |

| VERIFIED BY & DATE (PRODUCTION EXEC./ OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- “LOOSE BOX” LABEL:

- ‘LOOSE BOX’ Status Label shall be affixed on the box which contains loose Semi Finished or Finished Materials.

- Loose Box Label shall contain White Color background with text in Black Color.

- Specification of Loose Box Label shall be 7.0 mm (L) X 2.5 mm (H).

- Specimen of ‘LOOSE BOX’ Label is as shown in Annexure-XI.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| LOOSE BOX | 20 Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- “UNDER MAINTENANCE” LABEL:

- ‘UNDER MAINTENANCE’ Status Label shall be affixed on Machines / Equipments / Instruments which are under maintenance.

- Under Maintenance Label shall contain White Color background with text in Black Color.

- Under MaintenanceStatus Label shall be filled by Concerned Department Executive / Officer and affixed on that Machine / Equipment / Instrument which is under maintenance and shall be signed along with Date.

- Specification of Under Maintenance Label shall be 86.0 mm (L) × 56.0 mm (H).

- Specimen of ‘UNDER MAINTENANCE’ Label is as shown in Annexure-XII

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| UNDER MAINTENANCE | 11 Font Capital & Bold |

| EQUIPMENT / INSTRUMENT/ MACHINE NAME | 9 Font Capital & Bold |

| DEPARTMENT | 9 Font Capital & Bold |

| DATE | 9 Font Capital & Bold |

| OBSERVED BY (EXEC./ OFFICER) | 9 Font Capital & Bold |

| REMARKS | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

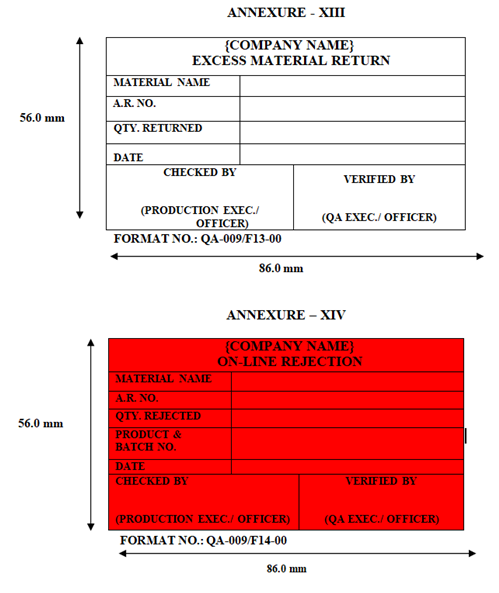

- “EXCESS MATERIAL RETURN” LABEL:

- ‘EXCESS MATERIAL RETURN’ Status Label shall be affixed on the unused material which is excess after completion of the process (In case of Packaging Material only).

- Coded material cannot be returned.

- Excess Material Return Label shall contain White Color background with text in Black Color.

- Excess Material Return Status Label shall be checked by Production Executive / Officer and verified by QA Executive / Officer and affixed on the excess material to be return to store on Material Return Note Slip /Material Return Note.

- Specification of Excess Material Return Label shall be 86.0 mm (L) × 56.0 mm (H).

- Specimen of ‘EXCESS MATERIAL RETURN’ Label is as shown in Annexure-XIII.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| EXCESS MATERIAL RETURN | 11 Font Capital & Bold |

| MATERIAL NAME | 9 Font Capital & Bold |

| A.R. NO. | 9 Font Capital & Bold |

| QTY. RETURNED | 9 Font Capital & Bold |

| DATE | 9 Font Capital & Bold |

| CHECKED BY (PRODUCTION EXEC. / OFFICER) | 9 Font Capital & Bold |

| VERIFIED BY (QA EXEC. / OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- “ON-LINE REJECTION” LABEL:

- ‘ON-LINE REJECTION’ Status Label shall be affixed on the material which is rejected during the Process / Packing Activity.

For Example: labels were rejected during packing process due to improper pasting, any raw material during Process / Shifting.

- On-Line Rejection Label shall contain Red background with text in Black Color.

- On-Line Rejection Label shall be checked by Production Executive / Officer and verified by QA Executive / Officer and affixed on On-Line Rejected Material to be return to warehouse on On-Line Rejection Note.

- Specification of On-Line Rejection Label shall be 86.0 mm (L)×56.0 mm (H).

- Specimen of ‘ON–LINE REJECTION’ Label is as shown in Annexure-XIV.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| ON-LINE REJECTION | 11 Font Capital & Bold |

| MATERIAL NAME | 9 Font Capital & Bold |

| A.R. NO. | 9 Font Capital & Bold |

| QTY. REJECTED | 9 Regular & Bold |

| PRODUCT & BATCH NO. | 9 Regular & Bold |

| DATE | 9 Regular & Bold |

| CHECKED BY (PRODUCTION EXEC. / OFFICER) | 9 Regular & Bold |

| VERIFIED BY (QA EXEC. / OFFICER) | 9 Regular & Bold |

| FORMAT NO. | 10 Normal & Capital |

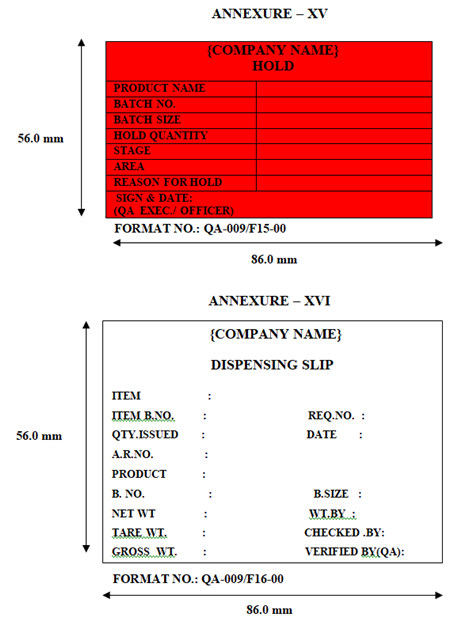

- “HOLD” LABEL:

- ‘HOLD’ Status Label shall be affixed on the Material (Raw material / Chemical / Reagent / Packaging Material), Semi-Finished / Finished Product which is hold due to some reason for further investigation.

- Hold Status Label shall contain Red Color background with text in Black Color.

- Hold Label shall be filled by QA Executive / Officer and shall be signed along with Date with reason for Hold.

- Specification of the Label shall be 86.0 mm (L) ×56.0 mm (H).

- Specimen of ‘HOLD’ Label is as shown in Annexure-XV.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| HOLD | 11 Font Capital & Bold |

| PRODUCT NAME | 9 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| BATCH SIZE | 9 Font Capital & Bold |

| HOLD QUANTITY | 9 Font Capital & Bold |

| STAGE | 9 Font Capital & Bold |

| AREA | 9 Font Capital & Bold |

| REASON FOR HOLD | 9 Font Capital & Bold |

| SIGN & DATE (QA EXEC./ OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Normal & Capital |

- “DISPENSING SLIP” LABEL:

- ‘DISPENSING SLIP’ Label shall be affixed on the Dispensed Raw & Packaging Material Containers / Poly Bags in Warehouse by Warehouse Person.

- Specification of Label shall be 86.0 mm (L) X 56.0 mm (H).

- ‘DISPENSING SLIP’ shall contain white background with text in Black

- Specimen of ‘DISPENSING SLIP’ Label is as shown in Annexure-XVI.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| DISPENSING SLIP | 11 Font Capital & Bold |

| ITEM | 9 Font Capital & Bold |

| ITEM B. NO. | 9 Font Capital & Bold |

| REQ. NO. | 9 Font Capital & Bold |

| QTY. ISSUED | 9 Font Capital & Bold |

| DATE | 9 Font Capital & Bold |

| A.R. NO. | 9 Font Capital & Bold |

| PRODUCT | 9 Font Capital & Bold |

| B. NO. | 9 Font Capital & Bold |

| B. SIZE | 9 Font Capital & Bold |

| NET WT. | 9 Font Capital & Bold |

| TARE WT. | 9 Font Capital & Bold |

| GRS WT. | 9 Font Capital & Bold |

| WT.BY | 9 Font Capital & Bold |

| CHECKED BY | 9 Font Capital & Bold |

| VERIFIED BY (QA) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

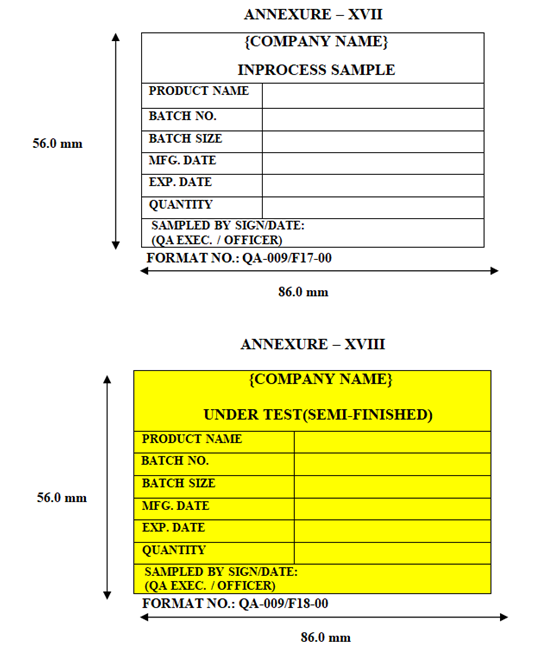

- “INPROCESS SAMPLE” LABEL (FOR QA USE ):

- ‘INPROCESS SAMPLE’ Label shall be affixed on Semi-Finished Sampled material which is for QC testing.

- In process sample Label shall contain White Color background with text in Black Color.

- In process sample Label shall be filled by QA Executive / Officer and shall be signed along with Date.

- Specification of the Label shall be 86.0 mm (L) X 56.0 mm (H).

- Specimen of ‘INPROCESS SAMPLE’ Label is as shown in Annexure-XVII.

- Label shall contain following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| IN PROCESS SAMPLE | 11 Font Capital & Bold |

| PRODUCT NAME | 11 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| BATCH SIZE | 9 Font Capital & Bold |

| MFG. DATE | 9 Font Capital & Bold |

| EXP. DATE | 9 Font Capital & Bold |

| QUANTITY | 9 Font Capital & Bold |

| SAMPLED BY SIGN/DATE (QA EXEC./OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- “UNDER TEST(SEMI-FINISHED)” LABEL (FOR QA USE ):

- ‘UNDER TEST’ Status Label shall be affixed on In-process testing material which is under testing.

- Under Test Label shall contain Yellow Color background with text in Black Color.

- Under Test Label shall be filled by QA Executive / Officer and shall be signed along with Date.

- Specification of the Label shall be 86.0 mm (L) X 56.0 mm (H).

- Specimen of ‘UNDER TEST (SEMI-FINISHED)’ Label is as shown in Annexure-XVIII.

Note: If for semi-finished stage waiting for release is not required then product status label shall be affixed at container.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| UNDER TEST(SEMI-FINISHED) | 11 Font Capital & Bold |

| PRODUCT NAME | 9 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| BATCH SIZE | 9 Font Capital & Bold |

| MFG. DATE | 9 Font Capital & Bold |

| EXP. DATE | 9 Font Capital & Bold |

| QUANTITY | 9 Font Capital & Bold |

| SAMPLED BY SIGN/DATE (QA EXEC. / OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

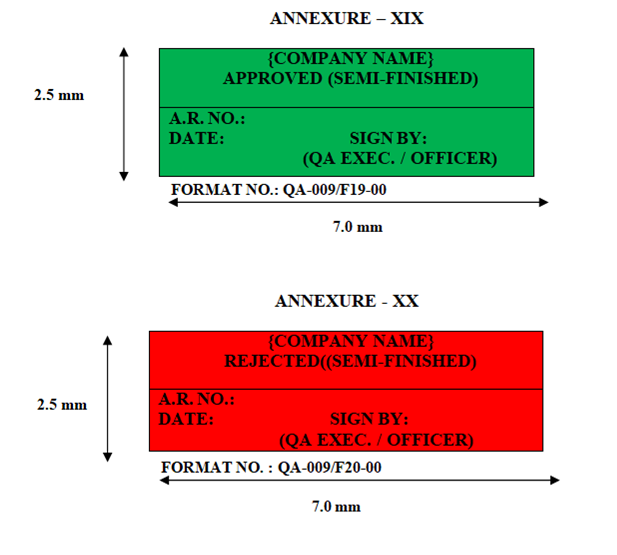

- “APPROVED(SEMI-FINISHED)” LABEL (FOR QA USE):

- ‘APPROVED (SEMI-FINISHED)’ Status Label shall be affixed on the In-process Semi Finished material which is approved by QC.

- Approved Label shall contain Green Color background with text in Black Color.

- Approved Label shall be filled by QA Executive / Officer and shall be signed along with Date.

- Specification of the Label shall be 7.0 mm (L) X 2.5 mm (H).

- Specimen of ‘APPROVED (SEMI-FINISHED)’ Label is as shown in Annexure-XIX.

Note: If for semi finished stage waiting for release is not required then product status label shall be affixed at container.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| APPROVED (SEMI-FINISHED) | 11 Font Capital & Bold |

| A.R. NO. | 9 Font Capital & Bold |

| DATE | 9 Font Capital & Bold |

| SIGN BY (Q.A. EXEC./ OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

“REJECTED(SEMI-FINISHED)” LABEL (FOR QA USE):

‘REJECTED (SEMI-FINISHED)’ Status Label shall be affixed on the in process Semi Finished material which is rejected by QA. For Example: Bulk sample fail by QC due to assay problem.

- Rejected Label shall contain Red Color withtext in Black Color.

- Rejected Label shall be filled by QA Executive / Officer and shall be signed along with Date.

- Specification of the Label shall be 7.0 mm (L) X 2.5 mm (H).

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| REJECTED (SEMI-FINISHED) | 11 Font Capital & Bold |

| A.R. NO. | 9 Font Capital & Bold |

| DATE | 9 Font Capital & Bold |

| SIGN BY (Q.A. EXEC./ OFFICER) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- Specimen of ‘REJECTED’ Label is as shown in Annexure-XX.

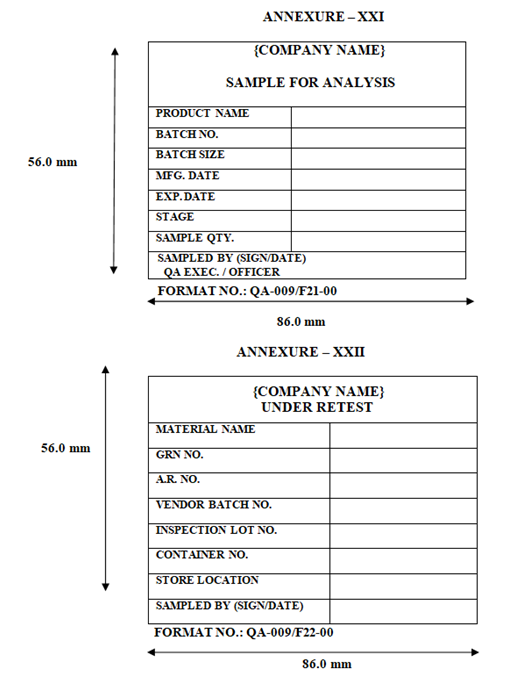

- “SAMPLE FOR ANALYSIS:

- At the time of In Process and Semi-finished & Packing stage QA officer affix the label of SAMPLE FOR ANALYSIS on the Sample bag in which sample is taking for testing.

- Specification of the Label shall be 86.0 mm (L) X 56.0 mm (H).

- Sample for Analysis Label shall be containing White Color background with textin Black Color.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| SAMPLE FOR ANALYSIS | 11 Font Capital & Bold |

| PRODUCT NAME | 9 Font Capital & Bold |

| BATCH NO. | 9 Font Capital & Bold |

| BATCH SIZE | 9 Font Capital & Bold |

| MFG. DATE | 9 Font Capital & Bold |

| EXP. DATE | 9 Font Capital & Bold |

| STAGE | 9 Font Capital & Bold |

| SAMPLE QTY. | 9 Font Capital & Bold |

| SAMPLED BY (SIGN/DATE) QA EXEC./OFFICER | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- Specimen of ‘SAMPLE FOR ANALYSIS’ Label is as shown in Annexure-XXI.

- “UNDER RETEST” LABEL:

- After sampling from the Quarantine Retest Material QC Officer shall sample and affix ‘UNDER RETEST’ Labelon the ‘QUARANTINE RETEST LABEL’, by overlapping the part where ‘QUARANTINE RETEST’ word is written.

- Specification of the Label shall be 86.0 mm (L) X 56.0 mm (H).

- Under Retest Label shall be contain White Color background with textin Black Color.

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| UNDER RETEST | 11 Font Capital & Bold |

| MATERIAL NAME | 9 Font Capital & Bold |

| GRN NO. | 9 Font Capital & Bold |

| A.R. NO. | 9 Font Capital & Bold |

| VENDOR BATCH NO. | 9 Font Capital & Bold |

| INSPECTION LOT. NO. | 9 Font Capital & Bold |

| CONTAINER NO. | 9 Font Capital & Bold |

| STORE LOCATION | 9 Font Capital & Bold |

| SAMPLED BY (SIGN/DATE) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- Specimen of ‘UNDER RETEST’ Label is as shown in Annexure-XXII.

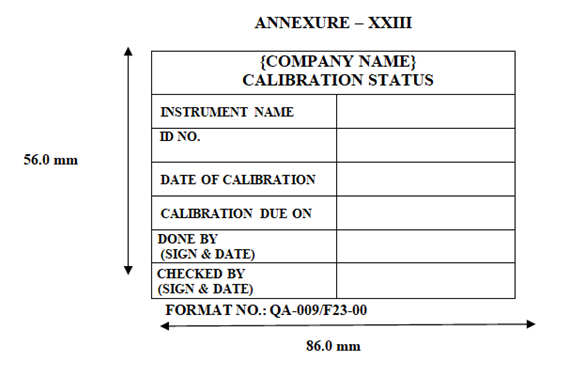

- “CALIBRATION STATUS” LABEL:

- ‘CALIBRATION STATUS’ Status Label shall be affixed on the instruments which are calibrated.

- Calibrated Label shall contain White Color background with text in Black Color.

- Calibrated Label shall be filled by Officer / Executive of the respective Department.

- Specification of the Label shall be 86.0 mm (L) X 56.0 mm (H).

Click the link to download the complete procedure:

https://pharmaguidehub.com/product/status-labeling/

- Label shall contain the following details:

| CONTENT OF LABEL | FONT SIZE & LETTER STYLE |

| {COMPANY NAME} | 11 Font Capital & Bold |

| CALIBRATION STATUS | 11 Font Capital & Bold |

| INSTRUMENT NAME | 9 Font Capital & Bold |

| ID NO. | 9 Font Capital & Bold |

| DATE OF CALIBRATION | 9 Font Capital & Bold |

| CALIBRATION DUE ON | 9 Font Capital & Bold |

| DONE BY (SIGN & DATE) | 9 Font Capital & Bold |

| CHECKED BY (SIGN & DATE) | 9 Font Capital & Bold |

| FORMAT NO. | 10 Font Capital & Bold |

- Specimen of ‘CALIBRATED’ Label is as shown in Annexure-XXIII.

REFERENCES:

Not Applicable

ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE | FORMAT No. |

| Annexure-I | Quarantine | QA-009/F01-00 |

| Annexure-II | Under Test | QA-009/F02-00 |

| Annexure-III | Q.C. Approved | QA-009/F03-00 |

| Annexure-IV | Rejected | QA-009/F04-00 |

| Annexure-V | Non-Recoverables | QA-009/F05-00 |

| Annexure-VI | To be Cleaned | QA-009/F06-00 |

| Annexure-VII | In process Status | QA-009/F07-00 |

| Annexure-VIII | Status Label | QA-009/F08-00 |

| Annexure-IX | Cleaned | QA-009/F09-00 |

| Annexure-X | Equipment Status | QA-009/F10-00 |

| Annexure-XI | Loose Box | QA-009/F11-00 |

| Annexure-XII | Under Maintenance | QA-009/F12-00 |

| Annexure-XIII | Excess Material Return | QA-009/F13-00 |

| Annexure-XIV | On-Line Rejection | QA-009/F14-00 |

| Annexure-XV | Hold | QA-009/F15-00 |

| Annexure- XVI | Dispensing Slip | QA-009/F16-00 |

| Annexure-XVII | Inprocess Sample | QA-009/F17-00 |

| Annexure-XVIII | Under Test (SEMI-FINISHED) | QA-009/F18-00 |

| Annexure-XIX | Approved (SEMI-FINISHED) | QA-009/F19-00 |

| Annexure-XX | Rejected (SEMI-FINISHED) | QA-009/F20-00 |

| Annexure-XXI | Sample For Analysis | QA-009/F21-00 |

| Annexure-XXII | Under Retest | QA-009/F22-00 |

| Annexure-XXIII | Calibration Status | QA-009/F23-00 |

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

| Controlled Copy No. 01 | : | Head Quality Assurance |

| Controlled Copy No. 02 | : | Head Warehouse |

| Controlled Copy No. 03 | : | Head Quality Control |

| Controlled Copy No. 04 | : | Head Production |

| Controlled Copy No. 05 | : | Head Engineering |

| Master Copy | : | Quality Assurance Department |

ABBREVIATIONS:

| SOP | : | Standard Operating Procedure |

| No. | : | Number |

| Ltd. | : | Limited |

| QA | : | Quality Assurance |

| IPCs | : | In–Process Containers |

| Exec. | : | Executive |

| L | : | Length |

| H | : | Height |

| Mfg. | : | Manufacturing |

| Exp. | : | Expiry |

| GRN No. | : | Goods Receipt Note Number |

| A.R. No. | : | Analytical Report Number |

| QC | : | Quality Control |

| G. Wt. | : | Gross Weight |

| ID No. | : | Identification Number |

| Regular | : | Running |

| Normal | : | Unbold |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

Click the link to download the complete procedure:

https://pharmaguidehub.com/product/status-labeling/