OBJECTIVE:

To lay down a procedure for Calibration of Moisture Analyzer (Make: Sartorius).

SCOPE:

This SOP is applicable to the procedure for Calibration of Moisture Analyzer (Make: Sartorius) at {Company Name} {Location}.

RESPONSIBILITY:

Officer/Executive/Designee: shall be responsible for following the procedure as per SOP.

Engineering Head/designee is responsible for compliance of SOP.

ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

PROCEDURE:

About Moisture Analyzer:

A moisture analyzer, also known as a moisture balance, is a laboratory instrument designed to accurately measure the moisture content of various substances.

It typically works on the principle of loss on drying (LOD).

The instrument combines a weighing scale with a heating element.

Working Procedure:

Sample Placement: A small sample of the material is placed on the weighing pan.

Initial Weight Measurement: The initial weight of the sample is recorded.

Heating: The sample is heated using a halogen lamp or infrared lamp. This heat evaporates the moisture present in the sample.

Continuous Weighing: As the moisture evaporates, the analyzer continuously measures the decreasing weight.

Drying Completion: When the weight stabilizes, it indicates that all the moisture has been removed.

Final Weight Measurement: The final weight of the dried sample is recorded.

Moisture Content Calculation: The difference between the initial and final weights represents the moisture content of the sample. This is usually expressed as a percentage.

Calibration Procedure:

Ensure that the Standard weights and Standard temperature adjustment set are in cleaned condition.

Ensure that the Standard weight box and Standard temperature adjustment set calibration is within the validity period.

Ensure that the Moisture Analyzer, which is to be calibrated, is externally clean.

Follow the procedure of SOP before and after completion of the Calibration activity.

Calibration frequency shall be followed for Moisture Analyzer as per the Master calibration schedule.

Calibration of Moisture Analyzer Weighing system:

- Ensure that the Moisture Analyzer spirit level is adjusted properly.

- Switch on the instrument power supply, the display shows “OFF”.

- Turn on the Moisture analyzer by pressing I/O key.

- Sartorius logo is displayed and self test Runs.

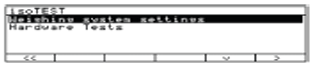

- Press the soft key ‘Test’ button step iso TEST function below screen is displayed.

Select the “weighing system setting” press the >soft key follow the screen displayed.

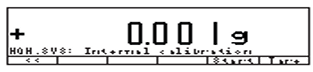

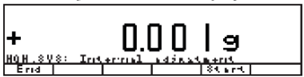

Select the “Internal calibration/adjustment “follow the screen will be displayed.

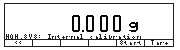

Select the “Start” soft key internal calibration adjustment value displayed.

If need adjustment press the “Start” soft key, automatically adjusted correct value.

Select the >>soft key return to main menu.

Select the “external calibration/adjustment with factory defined weight”

Follow the screen will be displayed.

Select the “Start” soft key follow the screen will be displayed.

Place the standard weight (e.g…50g) on the weighing system, (-) minus sign weight too low, plus sign weight too high follow the screen displayed.

If needs any error adjustment of the weighing system press “start” soft key error will be adjusted automatically.

After complete the adjustment press the “End” soft key the following screen will be displayed and automatically print out will come and take the 4 to 5 intermediate readings (minimum to maximum), readings shall be enter in to the Format-I.

Unload the weight from the weighing system.

Calibration of Moisture Analyzer Temperature:

Before start the temperature calibration open the sample chamber by pressing the (↓↑) key.

Ensure that the sample chamber is to be clean condition.

Remove the disposable pan and retainer, follow the procedure as shown in figure.

Moisture analyzer display shows ERR 54 or “L”.

Ensure that the standard temperature adjustment set carrying case by using disk holder remove and place the standard temperature adjustment set follow the procedure as shown in figure.

Ensure that the sample chamber shall be closed by pressing (↓↑) key.

Press the “Test” key, display shows in setup iso TEST functions “Heater adjustment”.

Select the “Heater adjustment” by pressing the >soft key.

Setup Display shows in “2-point temperature adjustment” and “1-point temperature adjustment”.

Select the “2-point temperature adjustment” by pressing the >soft key display as shown in figure.

Press the [Start] soft key to activate the temperature adjustment routine.

Moisture analyzer heating time and the previous drying time are displayed continuously.

After finished the measurement for calibration of the temperature an acoustic signal (3 beep tones) will get on the display.

Press [Info] soft key to display measured values.

If any values out of tolerance limits are displayed in “info” (calibration), press the (CF) soft key to exit.

Press the ‘Adjustment’ soft key the temperature adjustment automatically corrects value.

After completion of temperature adjustment press (CF) soft key return to the main menu and automatically print out will come, observed print out values shall be enter in to the Format-1.

Select the “1-point temperature adjustment” by pressing the >soft key.

By follow the procedure mentioned above observed print out value shall be enter in to the Format-I.

Acceptance criteria for the Moisture Analyzer weighing system are ±0.1% of standard weight and Temperature ±2°C of standard reading.

Sign off the calibration certificate by the respective person’s responsibility.

File the approved Calibration Certificate with Calibration Lab.

Based on the Calibration results prepare the Calibration status label.

Affixed/tag the Calibration status label as per SOP.

REFERENCES:

Not Applicable

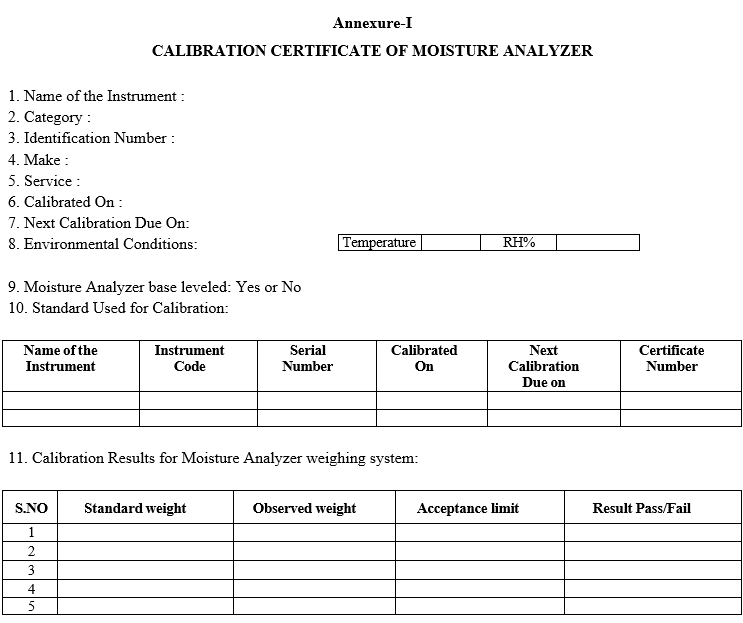

ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Calibration certificate of Moisture Analyzer |

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

Controlled Copy No. 01 : Head Quality Assurance

Controlled Copy No. 02 : Head Engineering

Master Copy : Quality Assurance Department

ABBREVIATIONS:

| No. | : | Number |

| CF | : | Clear function |

| SOP | : | Standard Operating Procedure |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

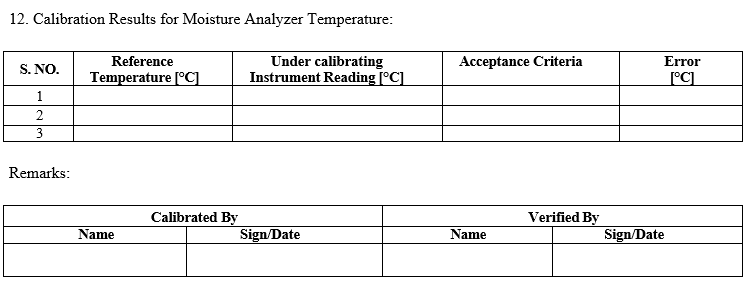

Annexure-I

CALIBRATION CERTIFICATE OF MOISTURE ANALYZER