OBJECTIVE:

To lay down the procedure for operation of deep freezer. Make –Haier.

SCOPE:

This SOP is applicable for the procedure for operation of deep freezer. Make –Haier at {Company Name} {Location}.

RESPONSIBILITY:

In charge- Microbiology- is responsible to ensure compliance as per SOP.

Head/Designee Quality Control – Shall be responsible for ensuring compliance as per SOP.

ACCOUNTABILITY:

QA Head shall be accountable for implementation of SOP.

About Deep Freezer:

Deep freezers are essential in the pharmaceutical industry for preserving temperature-sensitive materials like vaccines, enzymes, and biological samples. These specialized freezers maintain ultra-low temperatures, often reaching -20°C or lower, ensuring the stability and potency of these substances. They are equipped with advanced features like temperature monitoring, alarms, and backup power systems to guarantee uninterrupted cold storage. Proper maintenance and calibration of deep freezers are crucial to maintaining their performance and compliance with regulatory standards.

PROCEDURE:

Operation of Freezer:

Connect the power supply and switch ON the main.

The freezer will be ON and display screen will show the freezer’s internal temperature.

The freezer’s temperature is set and adjusted.

Unlocking:

When the lock indicator lights up, all keys except the “Digit Tran” key are locked. Press and hold the “Digit Tran” key for 5 seconds, the display area for internal temperature will show F0 and 0 will flash.

Then press the “Temp adjst” key, the display area for internal temperature will show F1.Finally press the Set key. The key board will unlock and the display panel will show internal temperature. If any key is pressed in 10 seconds, the key board will automatically be locked.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-deep-freezer-make-haier/

Temperature setting:

In initial power ON state , press “ Set” key , the display screen will show L0 and . “0 “will flash .Press this key again, the display screen will show the default temperature setting and the second digit will flash.(If the freezer is not used for the first time , the display screen will show the temperature set last time).

Adjust the freezer to the desired temperature by pressing the “ Digit tran” key to switch the flashing digit , and then press the “ set” key to confirm and memorize the temperature setting range (-20°C to -40°C).

High temperature alarm setting:

Alarm unlocking, press the set key the display screen will show L0 and 0 will flash, press the temp adjust key, the display screen will show L1.

Press the set key again the display screen will show the default temperature setting for high temperature alarm with the second digit flashing (the default temperature setting for high temperature alarm is internal temperature setting +10 ) and then adjust the temperature setting by pressing the “Digit tran key” to switch the flashing digit and pressing the “temp adjst” key to change the value and sign of current flashing digit after finishing setting press the set key to memorize the setting.

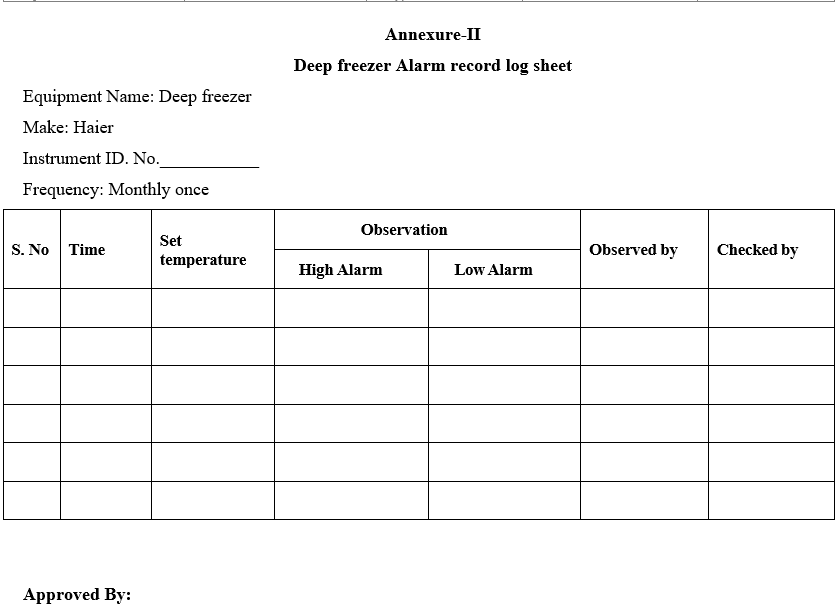

Temperature setting range for high temperature alarm. Maximum displayed temperature ≥ set temperature for high temperature alarm –set temperature ≥ 5 °C. Other wise use the default setting. 4.1.6.4 Note down the High temperature alarm result as per Format-II.

Low temperature alarm setting:

After unlocking the display screen will show L0 and 0 will flash. Press the temp “adjust key” twice, the display screen will show flashing L2.

Press the set key, the display screen will show the default temperature setting for low temperature alarm with the second digit flashing (the default temperature setting for low temperature alarm is internal temperature setting – 10).and then adjust the temperature setting by pressing the digit “tran key” to switch the flashing digit and pressing the temp “adjst key” to change the valute of current flashing digit.

After finishing setting , press the set key to memorise the setting. Temperature setting range for low temperature alarm. Minimum displayed temperature ≥ set temperature for low temperature alarm –set temperature ≥ 5 °C. Other wise use the default setting.

Note down the Low temperature alarm result as per Format-II.

Lock indicator:

If the indicator lights up, it means that all keys are locked to avoid misoperation.

Alarm indicator:

If the indicator lights up or flashes it means that a fault occurs.

Alarm test:

It is used to test normal working state of the alarm system and low battery charge level.

In the unlocked state press this key all the indicators will light up, the buzzer will give an alarm and all digital tubes display “8”.In the locked state ,press this key at the time of alarm, corresponding fault alarm code will display.

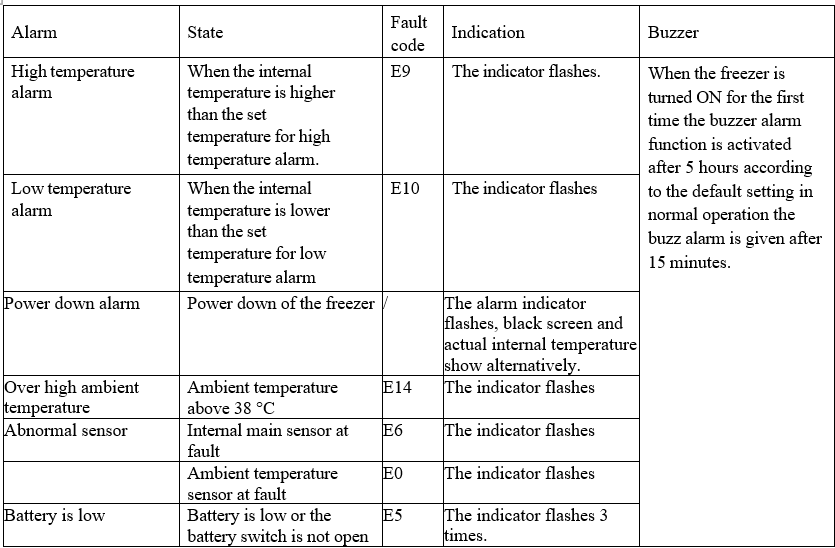

Identify the fault causes according to the table below.

Always turn ON the battery switch before starting the freezer.

The freezer will enter normal working state and charge the battery upon connecting to an AC power supply meeting its requirements. In case of AC power failure, the battery will energize the display screen for normal display.

When the voltage of battery reduces to less than a specified value due to discharge, it will stop energizing the display screen and thus the display screen will not display any longer.

When the battery is able to supply electricity normally to completely cut off the freezers power supply just pull out its AC power cord and turn off its battery switch.

Then the display screen will not display any longer.

Time setting for automatic alarm recovery;

At the time of alarm press the Cancel Buzz key on the display panel, buzz alarm will be cancelled.

If an alarm condition remains the buzz alarm will automatically recover after a pause of 30 minutes.

Unlock the chamber door of the heir to load/unload the articles inside the chamber.During the sample placement, make sure it has to stay in the confined area of tray.

Temperature shall be recorded manually in the morning (9:00 to 10:00) and in the evening (16:00 to 17:00) as per SOP

Temperature shall be maintained at -30°C± 5 °C.

If any deviation observed immediately, inform to Incharge Quality control to take the corrective action.

Call /Work order request to maintenance engineer in case of any break down.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-deep-freezer-make-haier/

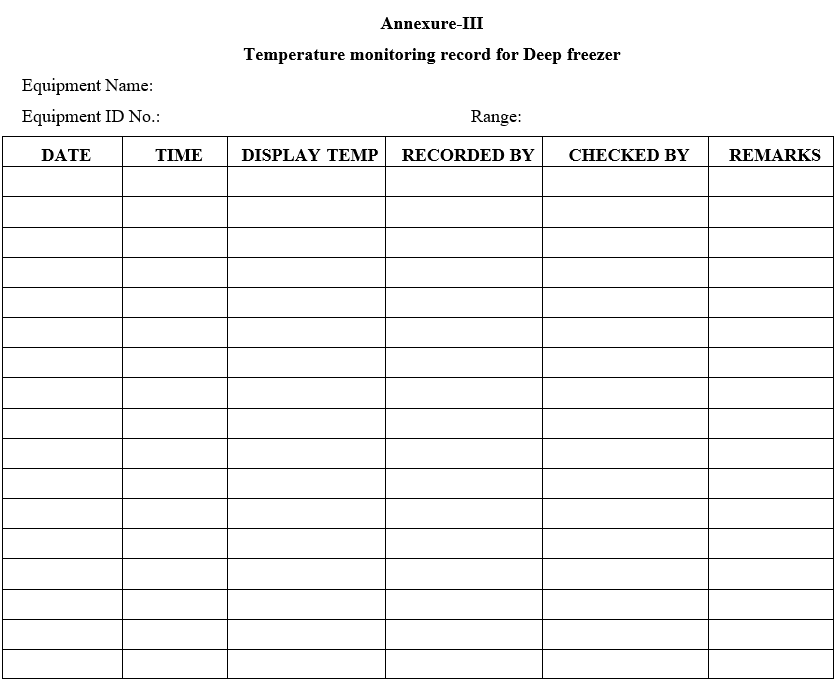

Daily temperature monitoring:

Every 30 minutes the software monitors the temperature and it is recorded & stored.

Take daily printouts from the software, review and retain the reports. In case of holiday take the printout on next working day.

Whenever there is a problem in software and if the temperature is not tracked in the scheduled intervals, Format 3 (Temperature monitoring record for Deep freezer) shall be recorded.

Safety precautions:

Ensure that the electrical switches are grounded.

Ensure that the chamber door is properly locked to avoid temperature leak.

Free space on the side of the trays shall be available.

Ensure that the sensor shall not blocked by the cultures.

Ensure that the air circulation shall not blocked by the cultures.

Door shall not be opened for more time to avoid the temperature excursion.

Whenever required, switch “OFF” the mains switch to shut down the deep freezer.

Temperature mapping procedure shall be followed as per SOP at a frequency of once in a year or after any major break down.

Note: Do not switched off the Deepfreeze power supply.

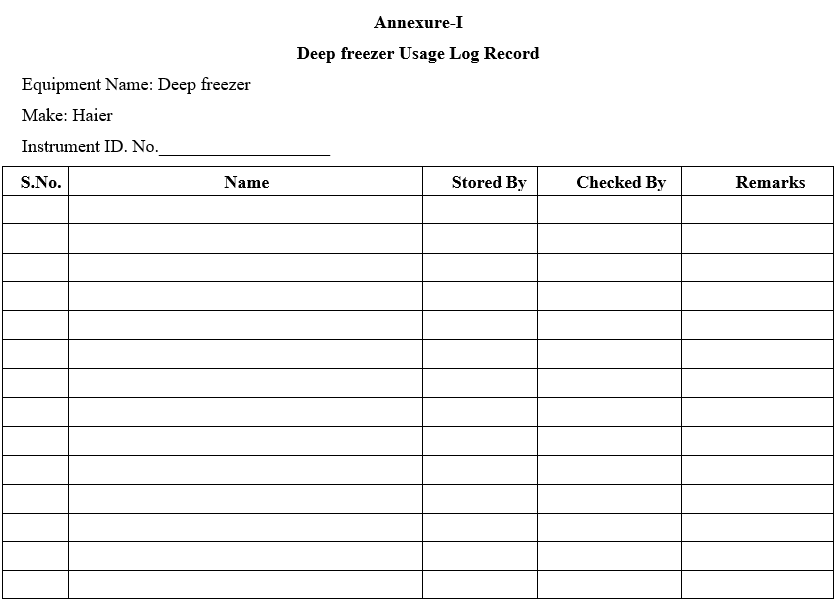

ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Deep freezer Usage Log Record |

| Annexure-II | Deep freezer Alarm record log sheet |

| Annexure-III | Temperature monitoring record for Deep freezer |

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Quality Control (Micro.)

- Master Copy : Quality Assurance Department

ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

Deep freezer Usage Log Record

Annexure-II

Deep freezer Alarm record log sheet

Annexure-III

Temperature monitoring record for Deep freezer

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-deep-freezer-make-haier/