OBJECTIVE:

The objective of this document is to define an approach for the Cleaning Validation Program and to harmonize the same by which {Company Name} will ensure compliance with National and International GMP requirements.

SCOPE:

This Policy is applicable to validation of cleaning processes employed at {Company Name} {Location} that may impact on the manufacture of cGMP categorized products.

DEFINITIONS:

The definitions listed here apply in the context of this Policy Document as well as for other documents used for the Cleaning Validation Program and may or may not be applicable in all other usage.

- Acceptance Criteria – The criteria a system/product/process must meet to successfully complete a test phase or to achieve delivery requirements.

- Acceptable Daily Exposure (ADE) – A dose that is unlikely to cause an adverse effect if an individual is exposed, by any route, at or below this dose every day for a lifetime.

- Action Limit – A limit that when reached requires an action to bring the process back under control.

- Alert Limit – A limit that when reached, alerts the staff that the process may be trending out of control.

- Automated Cleaning – Cleaning process that may or may not require equipment disassembly and uses preset values for cleaning solution (solvent and detergent), temperature and cycle time that are initiated by an operator for the system to automatically run. Any failures to meet the preset values will cause an alarm and report of the failure.

- Campaign Length – The predetermined maximum number of consecutive batches allowed in manufacturing or packaging within a single campaign and the maximum allowable time the equipment is used during manufacturing or packaging in a single campaign.

- CIP/WIP system – Cleaning in Place or Wash in Place system is normally an automated system with integrated equipment/ instruments, which shall enable to clean/ wash the equipment in place without dissembling

- Cleaning Process – A process of removal of contaminants/previous product remnants from the surface of the equipment/ system/ facility post usage by mechanical or automated means. This process may involve the use and removal of detergents.

- Cleaning Type A – Cleaning procedures that are followed between batches of the same product.

- Cleaning Type B– Cleaning procedures that are followed between batches of the same product for the equipments in which wet processing is carried out.

- Cleaning Type C – Cleaning procedures that are followed when changing over to a different product or after the campaign length.

- Cleaning Validation (CV) – A documented evidence that provides a high degree of assurance that the cleaning procedure shall consistently remove the residue of the products at or below acceptable levels.

To Establish the Cleaning Validation at your site please write us at pharmaguidehub@yahoo.com

- Cleaning Verification – The process of sampling and testing to confirm that a piece of equipment is clean.

- Dirty Hold Time – The time from the end of product manufacturing until it is cleaned.

- Grouping/ Bracketing – A strategy where products or equipment similar in design and function can be grouped when performing validation for the same cleaning procedures. The representative from the group/ bracket is usually considered the worst case.

- Health-Based Limit – A limit based on the health risks to patients as determined by a toxicological and pharmacological assessment. Also known as limited determined from the acceptable daily exposure (ADE) or permitted daily exposure (PDE).

- Manual Clean – A cleaning process that requires disassembly of equipment to perform direct cleaning using hand tool(s).

- Margin of Safety – The distance between the highest data point and the acceptance criteria.

- Maximum Allowable Carry Over (MACO) – Maximum amount of the residue of the previous product which is considered safe if passed into the next product batch. This is also termed as the Maximum Allowable Residue (MAR).

- Permitted Daily Exposure (PDE) – A substance-specific dose that is unlikely to cause an adverse effect if an individual is exposed at or below this dose every day for a lifetime.

- Product – A finished dosage form (tablet, capsule, vial, etc.) that contains one or more active pharmaceutical ingredients and possibly inactive ingredients. Products can either be made in commercial batches, or development batches for scale up or exhibition (submission).

- Product Dedicated Modules – A suite or portion of a facility that is segregated and dedicated to a product or group of products.

- Quality Risk Assessment – A systematic process for the assessment (identification, analysis and evaluation) of risks to the quality of the drug product across the product life cycle. Quality

- Risk Management – A proactive means to identify and control potential quality issues during research, development, manufacturing, and distribution of a product or service. The systematic application of management policies, procedures and practices to the tasks of analyzing, evaluating and controlling risk. Specifically, a systematic process for the assessment, control, communication and review of risks to the quality of the drug (medicinal) product across the product lifecycle.

- Recovery Factor – An established reproducible level of residue recovery from equipment surfaces.

- Residue – The traces or leftover material of the previous product or detergent.

- Revalidation – Validation of a previously validated system that has been changed or modified. Revalidation can be performed as the result of the change to the system, or a time based assessment.

- Routine Monitoring – The process of confirming equipment is clean to the limit after each cleaning process.

- Segregated Facility – A segregated or self-contained facility is either a separate building or an area within a building that is completely physically separated (floor to floor walls) with one or more rooms with its own air-locked personnel/material access, HVAC systems, processes, equipment and cleaning procedures.

- Therapeutic Dose – An amount of drug that will produce a pharmacological response.

- Validation – Documented evidence that the process, equipment, facilities or systems operating within established parameters, can perform effectively and reproducibly giving results meeting predetermined specifications.

- Validation Protocol – The written and approved document of an experimental sequence of tests that, when executed as prescribed, are intended to produce documented evidence that the equipment or system does what it is designed or claims to do reproducibly.

- Validation Report – A document summarizing the results derived from the execution of a protocol. The final report shall include a conclusion, which indicates validation success or failure and designates proven acceptable ranges for all critical process parameters as determined by the execution of the validation protocol.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-validation-policy/

- Visually Clean Criterion – Verification of absence of any visible residues such as drug product, dusts, liquids, oils or cleaners after cleaning under normal workspace lighting conditions when inspected with the eyes.

- Periodic Verification – The periodic process of confirming the cleaning process effectiveness through swabbing /rinsing and analytical testing as specified in a protocol study. This process shall be documented in a report.

DOCUMENTATION REQUIREMENTS:

- Procedure on Cleaning Validation Program

- Procedure on types of Cleaning

- Cleanability study procedure/protocol

- Determination of visual detection limits study procedure/protocol

- Procedure and training for visual inspection

- Procedure for validation of Analytical Methods/Protocol

- Hold Time study procedure/Protocol

POLICY:

General Considerations:

- Equipment/System/Facility is required to be cleaned post usage of product manufacturing and packaging and cleaning verified through routine monitoring to ensure that remnants of the previous product does not pass into the next product proposed to be manufactured above predetermined levels.

- Every Equipment/System/Facility shall have properly written cleaning procedure. This shall describe the method of cleaning, aids to be used while cleaning, details regarding timings, cleaning solvents quantity/amounts and detergents to be used (as required) during cleaning process.

- Every Equipment/System/Facility cleaning shall be documented. The cleaning document shall have a record of sequential steps involved in the cleaning process, the results of routine monitoring along with the activity done by and reviewed by details.

- Impact assessment for cleaning validation shall be done during introduction of new product in the facility to determine the requirement of formal cleanability study and to identify the need of cleaning validation.

- Routine monitoring consists of visually clean verification and if the limits are below the visual detection range a chemical analysis shall also be performed and documented.

- Toxicological assessments are to be completed and documented for each API and detergent/neutralizer.

- Hold time studies shall serve as a basis for defining time limits for holding and usage of the equipment/systems.

- Clean equipment and dirty equipment hold time study plans shall have rationale for selection of the equipment, material and timelines.

To Establish the Cleaning Validation at your site please write us at pharmaguidehub@yahoo.com

Cleaning Validation Program:

- Cleaning validation demonstrates that a specific cleaning procedure shall consistently remove the residues (of Active Pharma Ingredients, microbial, endotoxin and cleaning agents wherever applicable) to a Predetermined Level.

- Cleaning validation program requires various inputs including product list, ADE/ PDE, of APIs and detergents/ neutralizers, cleanability of products, solubility profile of the API, therapeutic doses (minimum and maximum daily doses), equipment train, product contact surface area of equipment/system, batch sizes, swab surface area or volume of the rinse to be collected. These details shall be updated, reviewed and approved as changes occur.

- Note: While calculating the equipment surface area, +5% of the obtained values may be taken to prevent error due to manual measurements.

- A Worst Case Product Approach shall be adopted for cleaning validations. Criteria for determining the worst case shall be based on a combination of solubility, hardest-to-clean and ADE/PDE/Potency within the same cleaning procedure.

- If the drug product contains multi active ingredients the cleaning shall be challenged on the ingredient which is worst case.

- Acceptable Residue Levels for shared facility shall be calculated using the Health-based limits formulae.

- For the dedicated facilities of multiple products of Penicillin and Cephalosporin acceptance residue levels shall be calculated by using Fourmen Mullen approach i.e. 10 PPM criterion / Dose criterion. The Minimum value obtained from both dose criterion and 10 PPM criterion shall be selected as the acceptance value for the cleaning validation.

- Where campaign manufacturing is carried out, the impact on the ease of cleaning at the end of campaign shall be considered and the maximum length of the campaign (in time and / or no. of batches) shall be determined.

- Hold time studies between the manufacturing and cleaning (dirty hold time) and time between cleaning and use (clean hold time) shall be determined.

Grouping/ Bracketing:

Cleaning procedures for similar equipment used for different drug products need not be validated individually.

A single validations study can be carried out which takes into account the “Worst case”. This practice is termed “Bracketing” or “Grouping”.

Examples of grouping / bracketing include:

- Grouping into product families (product family means similar physical-chemical properties, e.g. solubility)

- Grouping into equipment families (e.g. similar tablet presses, filling machines, vessels, storage containers)

Sampling Techniques:

Sampling shall be performed from clean equipment/systems using non- fiber shredding, noncontaminant clean room sampling aids. Sterile swabs shall be used for microbiological swab sampling.

Prior collection of samples from the equipment/system personnel shall ensure that equipment/ system are visually clean.

Sampling techniques are of various types and appropriate techniques shall be followed to collect the sample post cleaning.

- Direct sampling: This is swabbing method that allows collection of the samples directly from the cleaned equipment/system surfaces.

- These locations shall be finalized based on proper evaluation and are assumed to be generally difficult to clean surfaces, however shall be easily accessible.

- Indirect sampling: This is a rinsing method that generally involves collection of representative quantity of the solvent used in either the final stage of the cleaning/rinse or a separate final rinse after completion of cleaning.

- The solvent and quantity to be used shall be established during analytical method development.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-validation-policy/

Personnel shall wear appropriate clean room gowning and adequate care shall be taken not to contaminate the clean equipment while sampling.

Samples shall be analyzed for estimating the API, detergent by validated analytical methods.

Samples shall be analyzed for estimating the microbial and endotoxin contamination by validated analytical methods.Post sampling, the clean equipment/system shall be handled in a manner as written down in the equipment cleaning procedures.

A recovery Factor shall be established on various product contact surfaces (e.g. Stainless Steel, PVC, Glass, Silicone etc.) during analytical method validations.

Note: Recovery factor shall be determined on product contact surfaces those surface area is greater than 5% of the total product contact surface area.

The Recovery study shall always be targeted to achieve not less than 75%; Recoveries below this range shall be supported with sound scientific rationale and justification. Recovery factor shall be considered while estimating the residue.

The analytical studies shall also consider the sample hold time studies by simulating the storage condition of cleaning validation samples.

Limits Determination:

The limit/acceptance criteria shall be defined/determined as an actual numerical value and listed in the cleaning validation protocol The limits (Maximum Allowable Carry Over) can be calculated using Microsoft (MS) Excel Spread Sheets., these shall be adequately qualified/ validated before use.

Statistical tools can be employed to determine alert and action limits for the cleaning processes.

Visual residue limit (VRL) shall be established on various product contact surfaces (e.g. Stainless Steel, PVC, Glass, Silicone etc.) during analytical method validations.

Studies shall be performed and documented to determine the visual residue limit.

Note: VRL shall be determined on product contact surfaces those surface area is greater than 5% of the total product contact surface area.

Whenever the cleaning limits are not achievable any one or a group of below given options may be used with proper justification documented in the cleaning validation protocols:

- Improve the cleaning method

- Increase in swab surface areas,

- Update the analytical method to lower Limit of Quantification (LOQ)/ Limit of Detection (LOD).

- Decrease the amount of shared surface area by dedicating product contact parts or using disposable product contact parts.

- Control production order so that the product combinations, which produce limits that are not achievable, do not occur.

- Increase batch size of the product

For detergents (if applicable) the limits shall be based on toxicity levels and if the data is not available, preferred limits would be NMT 5 PPM.

Documentation:

Cleanability study, Analytical method validation, Visual residue detection study and Cleaning validation shall be performed using approved validation protocols. Results shall be recorded in the respective reports.

The results will state the actual residue amount measured and in the case of below the level of detection results the results will be recorded as < “insert the limit of detection”. The results of the cleaning validation shall consistently demonstrate that the worst-case product is cleaned to acceptable residue levels for a minimum of three consecutive batches.

In case the cleaning validations for three consecutive batches are incomplete to prepare the final summary, an Interim Report shall be made with available data and whenever the remaining batches data is available a Final Summary Report shall be prepared.

Training Aspects:

Personnel involved in cleaning shall be adequately trained on the cleaning procedures.

Personnel involved in the cleaning validation study shall be adequately trained on the study plan in techniques relating to sampling, sample handling and analysis.

The personnel involved in the analytical method development shall be qualified for recovery testing; spiking studies may be adopted to qualify personnel for recovery testing.

Personnel involved in visual cleanliness verification shall be subjected for eye examination on periodic frequencies.

Cleaning Validation Failure Considerations:

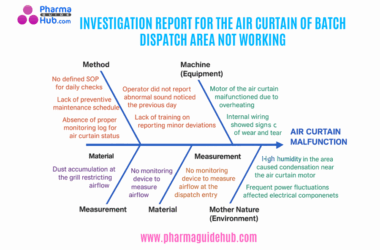

Whenever a failure is observed during cleaning validation, an investigation shall be conducted. Root cause or probable cause shall be determined and an adequate control measure shall be put in place.

Once the control measure is in place, cleaning validation shall be repeated.

Cleaning Validations – Other Aspects:

Validation activity shall be extended to cleaning process including area cleaning, garments washing cycles, filters cleaning cycles, in-process containers cleaning cycles, dispensing/ sampling tools cleaning.

Cleaning validation study for the above activities shall be conducted using approved validation protocols and results shall be recorded in reports.

The acceptance limit for area and filters shall be 100 PPM per swab area/visually clean.

Review and Revision/Re -validation criteria:

The cleaning procedures effectiveness shall be verified on at least on an annual basis.

The worst case product in the areas shall be selected.

This periodic cleaning verification shall be done through approved protocols; results shall be compiled in reports.

If the worst case product does not cover all equipment/systems in area then next worst case product using the equipment/systems not covered shall also be selected for the study.

Statistical tools can be employed to analyze the residue data and ensure an adequate margin of safety is maintained.

Whenever following changes are necessitated, a comprehensive Impact Assessment for evaluating the requirement of re-validations of cleaning procedures shall be done-

- Addition of new product

- Change in product contact surface area/equipment chain

- Change in batch sizes

- MACO Values decreased

- Different process formula etc.

In addition cleaning validation shall be repeated in case on risk basis –

- Change in cleaning agent or its concentration.

- Change in the cleaning procedure.

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New policy introduced | Not Applicable | To Be Written Manual |

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-validation-policy/