OBJECTIVE:

To lay down a Procedure for the operation of 2000 Liter Bin Blender (Make- SAAN).

SCOPE:

The scope of this SOP is procedure for operation of 2000 Liter Bin Blender (Make- SAAN).

RESPONSIBILITY:

Initiator Officer/Designee: Production shall perform the operation activity of 2000 Litre Bin Blender (Make- Saan).

Initiator Executive/Designee: Production shall ensure the compliance of the SOP

ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

ABOUT BIN BLENDER:

Bin blenders, also known as IBC blenders, are widely used in the pharmaceutical industry for their efficiency and flexibility in blending dry powders and granules. They operate by rotating a container or “bin” holding the materials, creating a tumbling action that ensures uniform mixing.

Key features and benefits of bin blenders in pharma:

- Versatility: Accommodate various container sizes and batch volumes, making them adaptable for different production scales.

- Efficient mixing: Achieve homogeneous blends, even with materials of varying particle sizes and densities.

- Easy handling and transfer: Sealed bins can be easily transported between processing stations, reducing manual handling and contamination risks.

- Enhanced cleaning and maintenance: Detachable bins allow for easy cleaning and maintenance, minimizing downtime.

- Flexibility: Can be used for blending a wide range of materials, including powders, granules, and some liquids.

Bin blenders play a crucial role in ensuring the quality and consistency of pharmaceutical products, particularly in tablet and capsule manufacturing. Sources and related content

PROCEDURE:

Check for the cleanliness of the area and machine.

Line clearance shall be taken from IPQA before starting the operation.

Remove the “CLEANED” label and paste it into the BPRR and affix “UNDER PROCESS” label.

Transfer all the materials to be lubricated as per the BPRR to the blending area.

Set- Up

Fixing of the Sieve

Switch ON the mains.

Release the Emergency push mushroom button.

Inch the Blender to check the working of blender and bring the blender to the position to insert the IBC bin.

Open the lock it by means of the hand wheel (on the rear side) for rotation Check the sieve size for correctness as mentioned in the BMR.

OPERATION:

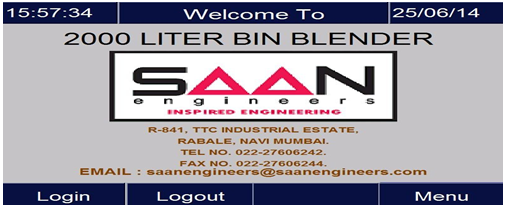

Switch on the main power supply, the following screen will display.

Login: – Touch Login key to log in to the system, enter the correct password with the help of numeric keys.

Logout: – Touch logout key to logout from the current user level.

Menu: – Touch menu key to go to the menu screen. Logout: – Touch this key to logout from the current user level.

Mode: – Touch mode key to select the mode (blending & lifting).

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-2000-liter-bin-blender-make-saan/

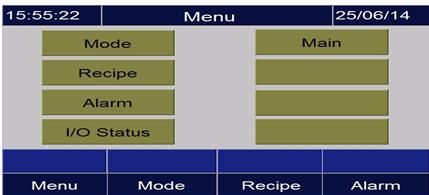

Recipe: – Touch recipe key to go to recipe screen.

Alarm: – Touch alarm key to see all alarm (problems) history in this screen.

I/O Status: – Touch I/O Status key to see current status of inputs & outputs.

Main: – Touch main key to go to main screen.

Menu: – Touch menu key to go to the menu screen.

Mode: – Touch mode key to select mode (blending & Lifting).

Recipe: – Touch recipe key to go to recipe screen.

Alarm: – Touch alarm key to see all alarm (problems) history in this screen.

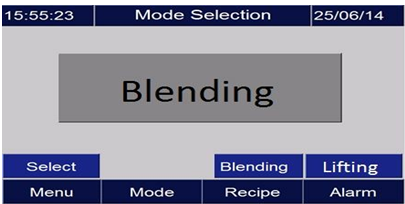

Mode: – Touch mode key to select mode (blending & Lifting).

Recipe: – Touch recipe key to go to recipe screen.

Alarm: – Touch alarm key to see all alarm (problems) history in this screen.

Select: – For selection of any command “blending” and “Lifting” touch the respective key followed by “select” key.

Lifting: – Press Lifting key for lifting of the bin up/down.

Blending: – Press Blending key to start the blending cycle.

Menu: Press the Menu key to go to the menu screen.

Mode: – User can select mode by pressing Mode key (blending & Lifting).

Recipe: – User can go to recipe screen by pressing Recipe key.

Alarm: – User can see all alarm (problems) history in this screen by touching Alarm key.

BIN MOVING UP: –

Bin Up: – Touch Bin Up key to operate the bin for lifting up position and when the Bin is lifted fully it stops generating the alarm Bin Fully Up.

Bin Down: – Touch Bin down key to operate the bin lifting down position when the Bin is fully down it stops generating the alarm Bin Fully Down.

Mode: -Press mode key to go to mode menu.

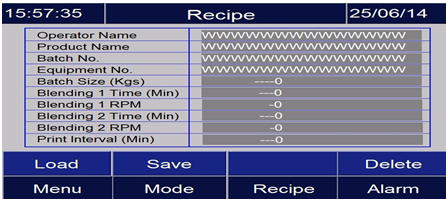

RECIPE: –

Load: – User can load the recipe by pressing load key from the saved recipe

Save: – After pressing Save button system will ask option for “save recipe as”. Enter appropriate alphanumeric value to save. If the user saves recipe with same recipe already entered, then system will ask for overwrite. Press “Ok” Button to overwrite. Press “cancel” to exit.

Delete: – User can delete the recipe by pressing delete key

Menu: – press menu key to go to menu screen.

Mode: – User can select mode by press mode key (e.g. blending, discharge mode).

Recipe: -User can go to recipe screen by using recipe key.

Alarm: – User can see all alarm (problems) history in this screen.

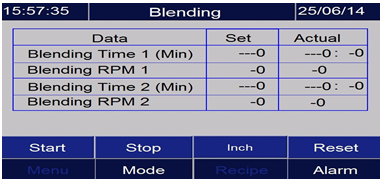

BLENDING: –

Start: -Press the start key to start the blending process.

Stop: – Press stop key to stop the auto cycle if necessary, during running cycle.

Reset: -Press reset key to reset the process.

Inch: – Press inch key for slight movement of the blender.

Mode: – Press mode key to go mode screen. This key is inactive during blending cycle running.

Alarm: – User can see all alarm (problems) history in this screen.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-2000-liter-bin-blender-make-saan/

LOADING AND BLENDING OF THE IBC BIN:

Check that the bin arm is opened.

Insert the bin to be blended in the blender arm by manual push.

Check that the bin arm is closed and locked by the help of hand wheel.

The Lubricants material will be picked up and transferred manually through the top lid of bin into the blender.

After all the Lubricants material transferred to the blender close the top lid with help of eye bolt.

Ensure that no Lubricants material to be added is left in the cage.

Press the bin up button and take the bin up.

Remove the bin trolley and all obstruction from the blender sweep area and close the safety guards surrounding the blender.

Switch on the mode to blending mode from the control panel.

Set the desired blending time (as per the BPRR) in the HMI in Auto mode F Precaution: Check that no person is inside the safety railing and that there is no obstruction to the rotating blender F Check that all the materials to be mixed are loaded in the blender as per BPRR before starting the mixing operation.

Press the blender start button in HMI and the blender will start rotating. Record the timings in the BPRR of the product.

After completion of the blending time, the blender will stop automatically in auto mode.

Rotate the blender manually by inching the machine so that discharge butterfly valve of IBC is at the bottom.

UNLOADING OF THE IBC BIN

Open the safety guards surrounding the blender.

Place the trolley of IBC below the IBC bin in the guiding track of trolley.

Go to the bin up/down mode and press the bin down key.

Check that the supporting arm of IBC bin lands on the holding arms of trolley.

Record the details in the BPRR.

Check that the mains are switched off after completion of operation of the blender.

Record the operation of the machine in the respective Equipment Logbook.

Remove the “UNDER PROCESS” label and affix the “TO BE CLEANED” label over the “UNDER PROCESS” label.

REFERENCES:

Not Applicable

ANNEXURES:

Not Applicable

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

Master Copy : Quality Assurance Department

Controlled Copy No. 01 : Head Quality Assurance

Controlled Copy No. 02 : Head Production

ABBREVIATIONS:

| IPC | : | In process containers. |

| IPQA | : | In process quality Assurance. |

| BMR | : | Batch Manufacturing Record |

| BPR | : | Batch Packing Record |

| SOP | : | Standard operating procedure |

| QA | : | Quality Assurance |

| HMI | : | Human Machine Interface. |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-2000-liter-bin-blender-make-saan/