INSTALLATION QUALIFICATION PROTOCOL CUM REPORT FOR FLUID BED PROCESSOR

The Installation Qualification (IQ) protocol and report for a Fluid Bed Processor meticulously documents the equipment’s proper installation. This ensures adherence to design specifications and regulatory requirements. The protocol outlines verification procedures for critical components, including utilities (electrical, compressed air), mechanical integrity, and software installation. Checks are performed to confirm placement, connections, and calibration of sensors and instrumentation. The report compiles the executed protocol, documenting observed results and any deviations. It provides traceable evidence that the processor is installed correctly and ready for operational qualification, establishing a foundation for consistent and reliable processing.

ABOUT FBP:

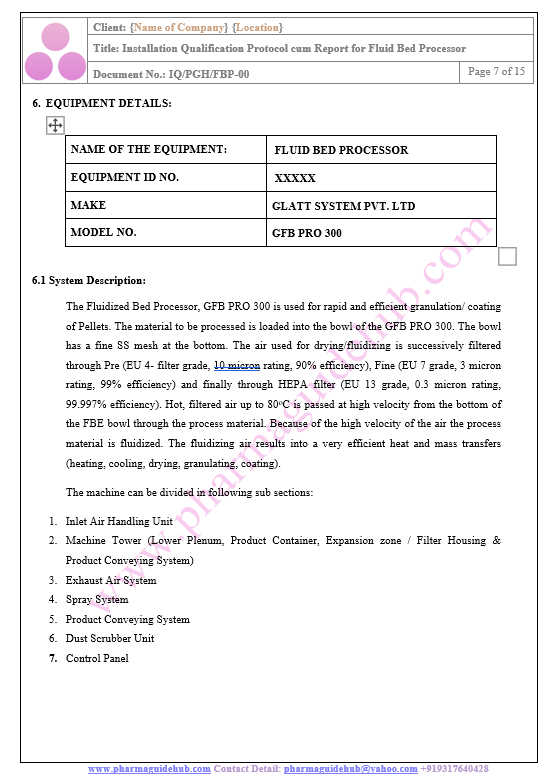

MAKE: GLATT SYSTEM PVT. LTD

MODEL NO.: GFB PRO 300

The Fluidized Bed Processor, GFB PRO 300 is used for rapid and efficient granulation/ coating of Pellets. The material to be processed is loaded into the bowl of the GFB PRO 300. The bowl has a fine SS mesh at the bottom. The air used for drying/fluidizing is successively filtered through Pre (EU 4- filter grade, 10 micron rating, 90% efficiency), Fine (EU 7 grade, 3 micron rating, 99% efficiency) and finally through HEPA filter (EU 13 grade, 0.3 micron rating, 99.997% efficiency). Hot, filtered air up to 80oC is passed at high velocity from the bottom of the FBE bowl through the process material. Because of the high velocity of the air the process material is fluidized. The fluidizing air results into a very efficient heat and mass transfers (heating, cooling, drying, granulating, coating).

Key Parameter of Below Page:

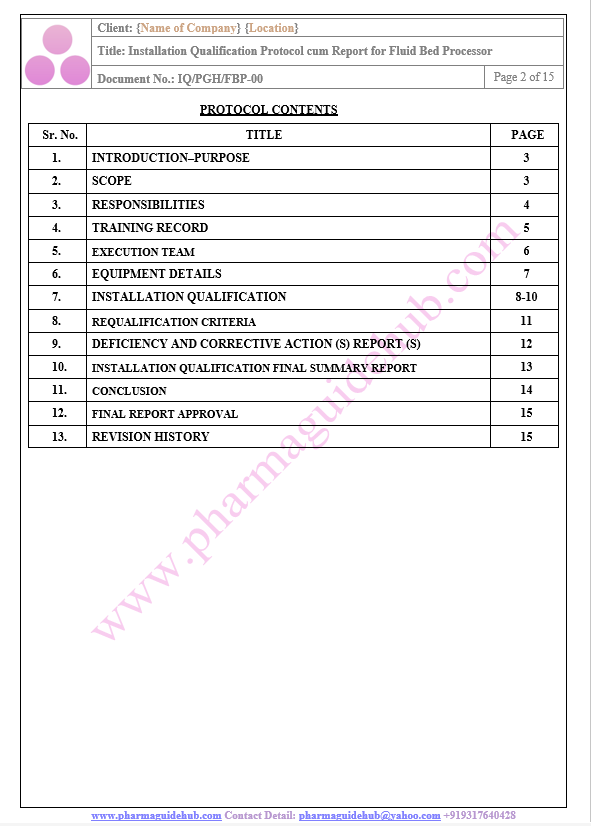

PROTOCOL CONTENTS

Find below pages for complete protocol:

Key Parameter of Below Page:

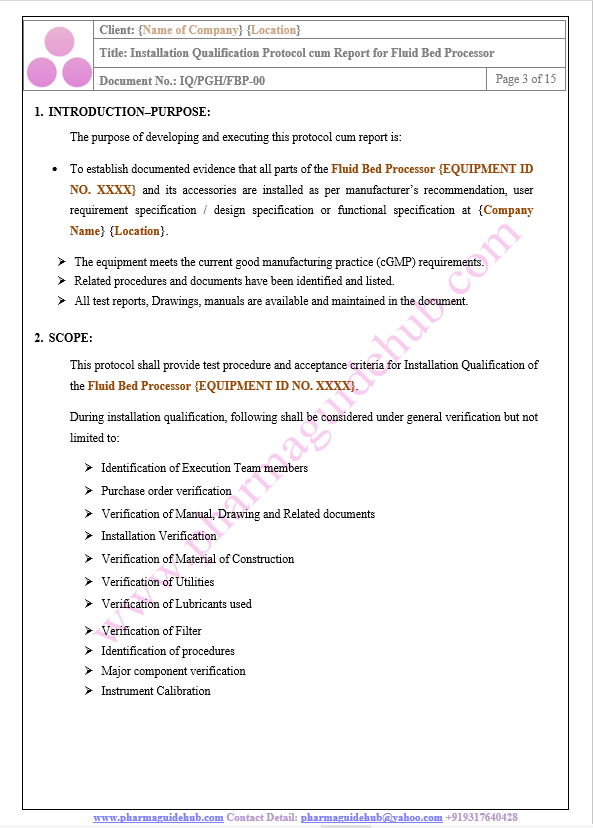

INTRODUCTION–PURPOSE

SCOPE

Find below pages for complete protocol:

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/installation-qualification-protocol-cum-report-for-fluid-bed-processor/

Key Parameter of Below Page:

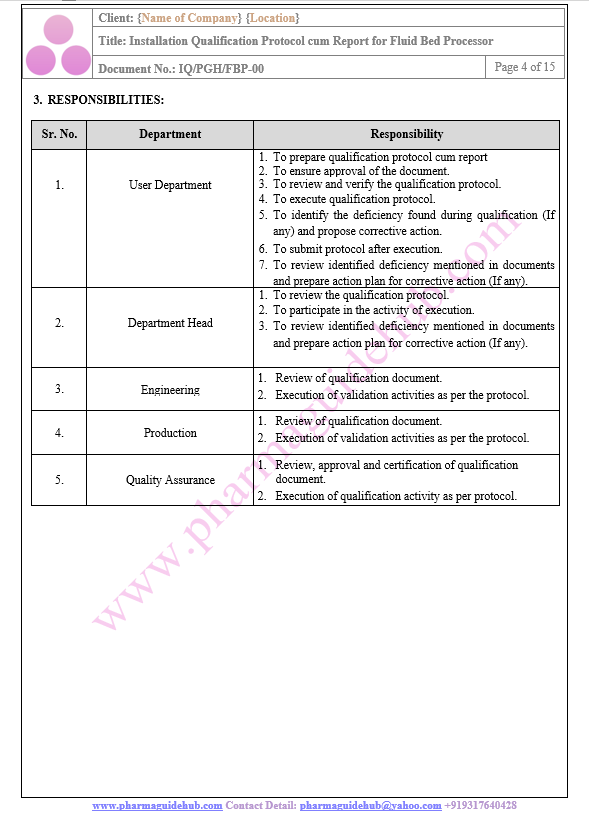

RESPONSIBILITIES

Find below pages for complete protocol:

For the Execution of Qualification activity at site, Please write us at pharmaguidehub@yahoo.com

Key Parameter of Below Page:

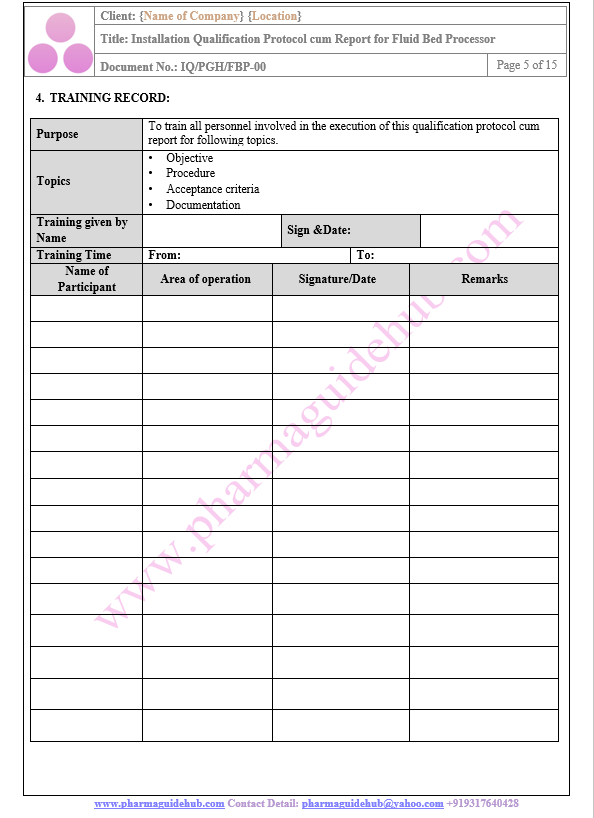

TRAINING RECORD

Find below pages for complete protocol:

Key Parameter of Below Page:

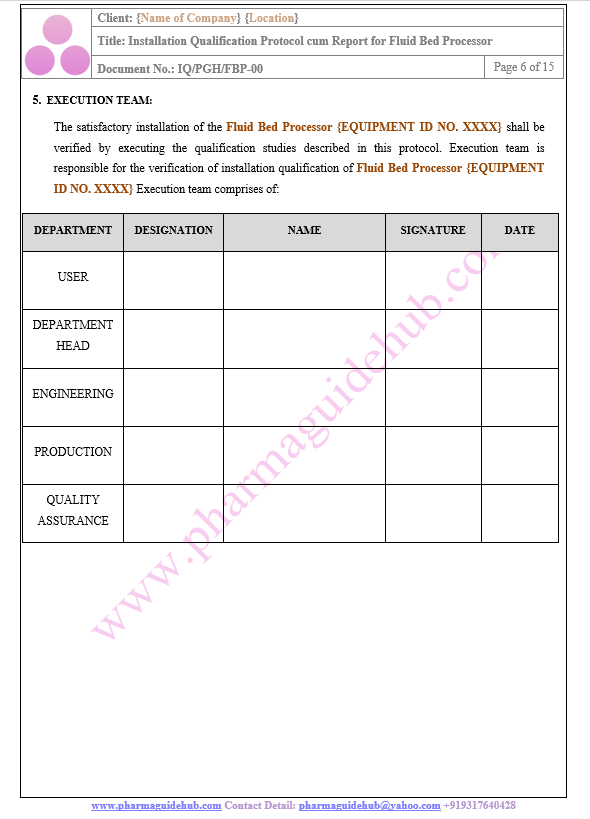

EXECUTION TEAM

Find below pages for complete protocol:

Key Parameter of Below Page:

EQUIPMENT DETAILS

Find below pages for complete protocol:

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/installation-qualification-protocol-cum-report-for-fluid-bed-processor/

Key Parameter of Below Page:

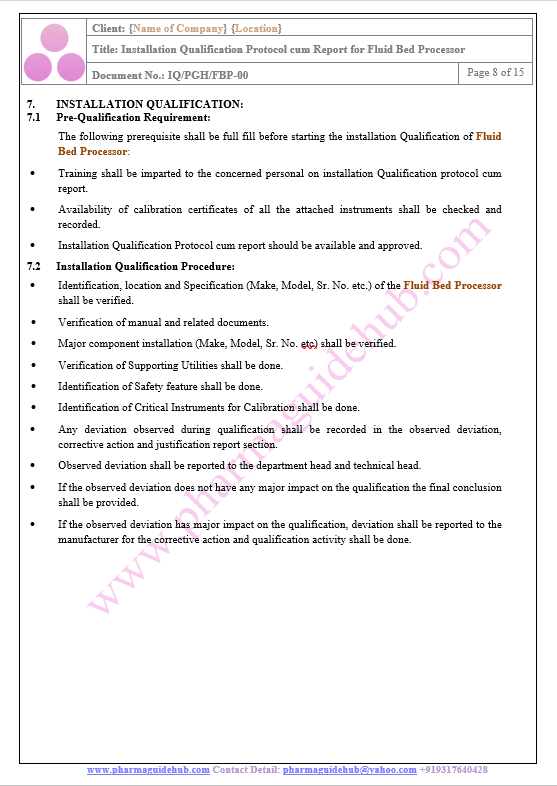

INSTALLATION QUALIFICATION

Find below pages for complete protocol:

Key Parameter of Below Page:

INSTALLATION QUALIFICATION

Find below pages for complete protocol:

Key Parameter of Below Page:

INSTALLATION QUALIFICATION

Find below pages for complete protocol:

For the Execution of Qualification activity at site, Please write us at pharmaguidehub@yahoo.com

Key Parameter of Below Page:

REQUALIFICATION CRITERIA

Find below pages for complete protocol:

Key Parameter of Below Page:

DEFICIENCY AND CORRECTIVE ACTION (S) REPORT (S)

Find below pages for complete protocol:

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/installation-qualification-protocol-cum-report-for-fluid-bed-processor/

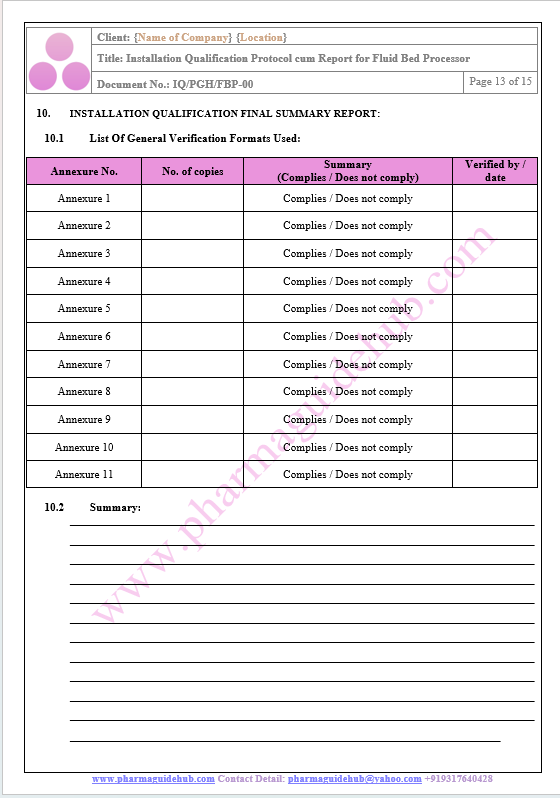

Key Parameter of Below Page:

INSTALLATION QUALIFICATION FINAL SUMMARY REPORT

Find below pages for complete protocol:

Key Parameter of Below Page:

CONCLUSION

Find below pages for complete protocol:

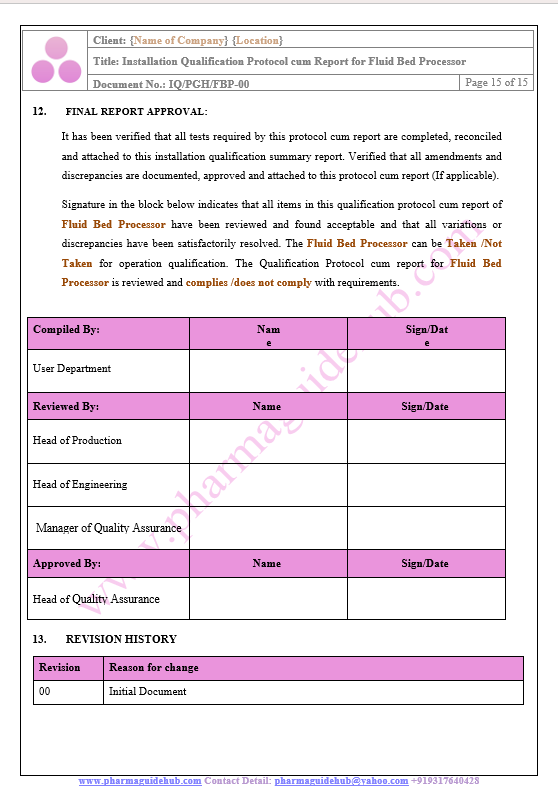

Key Parameter of Below Page:

FINAL REPORT APPROVAL

REVISION HISTORY

Find below pages for complete protocol:

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/installation-qualification-protocol-cum-report-for-fluid-bed-processor/

Link for Part 2 of 2:

https://pharmaguidehub.com/installation-qualification-protocol-cum-report-for-fluid-bed-processor-part-2-of-2/