Batch yield is a crucial metric in pharmaceutical manufacturing that measures the efficiency of a production process. It represents the ratio of the actual output to the theoretical maximum output. This calculation helps manufacturers assess the effectiveness of their production methods, identify areas for improvement, and optimize resource utilization.

Calculation Formula:

Batch Yield = (Actual Output / Theoretical Output) * 100%

Theoretical Output: The maximum possible quantity of product that could be produced based on the input materials and process efficiency.

Actual Output: The quantity of product produced in a specific batch.

Production yield is a value in % that results from dividing the number of good units (output) by the total number of units (input).

Production Yield Calculation Formula

Yield Percentage (%) = (No. of actual unit ÷ No. of theoretical unit) X 100

or

Yield Percentage (%) = (Actual quantity of goods produced/Theoretical quantity of goods expected) X 100

Batch Yield Calculation Formula

%Yield = (Actual Quantity of Good Products ÷ Theoretical Quantity of Batch size) X 100

For example,

If a product batch size is 100,000 pcs and number of good product is 95,000 pcs, the % yield will be –

%Yield = (95,000 ÷ 100,000) × 100 = 95%

In pharmaceutical industry, the yield percentage (%) is determined at the conclusion of each appropriate phase of manufacturing, processing, packaging, or holding of the drug product.

For yield calculation at compression stage,

Yield as percentage (%) = (A ÷ B) X 100 %

Here,

B = Weight of granules for compression

A = Weight of accepted tablets

For example,

If the weight of granules for compression is 550 kg and weight of accepted tablets is 540 kg; thus actual yield will be –

(540 ÷ 550) X 100 % = 98.18 %

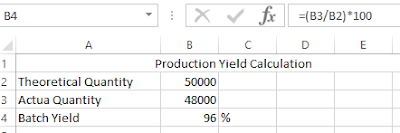

Production Yield Calculation in Excel

As per 21 CFR 211.103,

Actual yields and percentages of theoretical yield shall be determined at the conclusion of each appropriate phase of manufacturing, processing, packaging, or holding of the drug product. Such calculations shall either be performed by one person and independently verified by a second person, or, if the yield is calculated by automated equipment under § 211.68, be independently verified by one person.

Factors Affecting Batch Yield:

Regulatory Compliance: Adherence to regulatory standards and guidelines can influence yield. For example, strict quality control measures might lead to higher rejection rates, affecting overall yield.

Process Losses: These can include material losses during handling, storage, and processing, as well as product waste due to errors or inefficiencies.

Equipment Efficiency: The performance of manufacturing equipment can significantly impact yield. Factors such as wear and tear, maintenance, and operator skill can influence equipment efficiency.

Raw Material Quality: The quality of the raw materials used in the production process can affect the final yield. Impurities or variations in raw materials can lead to lower yields or product defects.

Process Optimization: The effectiveness of the production process itself, including factors like temperature control, mixing efficiency, and reaction times, can impact yield.