OBJECTIVE:

To lay down the procedure for calibration and temperature mapping of deep freezer.

SCOPE:

This SOP is applicable for the procedure for calibration and temperature mapping of deep freezer at {Company Name} {Location}.

RESPONSIBILITY:

Microbiologist: is responsible to perform the activity as per SOP.

In charge- Microbiology- is responsible to ensure compliance as per SOP.

Head/Designee Quality Control – Shall be responsible for ensuring compliance as per SOP.

ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

About Deep Freezer Calibration and Thermal Mapping:

Calibration and temperature mapping of deep freezers are crucial for maintaining the integrity of stored samples. Calibration ensures the accuracy of the freezer’s temperature display, while temperature mapping assesses the temperature uniformity throughout the storage space. This process involves placing calibrated temperature sensors at various locations within the freezer and recording data over a specified period. By analyzing the collected data, any temperature deviations or hotspots can be identified and addressed, ensuring optimal storage conditions for sensitive materials. Regular calibration and mapping are essential for compliance with regulatory standards and maintaining the quality of stored samples.

PROCEDURE:

Place the calibrated Thermometer inside the Deep freezer and wait for 5 minutes.

Observe the temperature for period of 8 hours and the temperature shall be recorded at an interval of 30 minutes.

Note down the temperature of Thermometer and compare it with that of Deep freezer display temperature.

The frequency of calibration shall be performed once in a month.

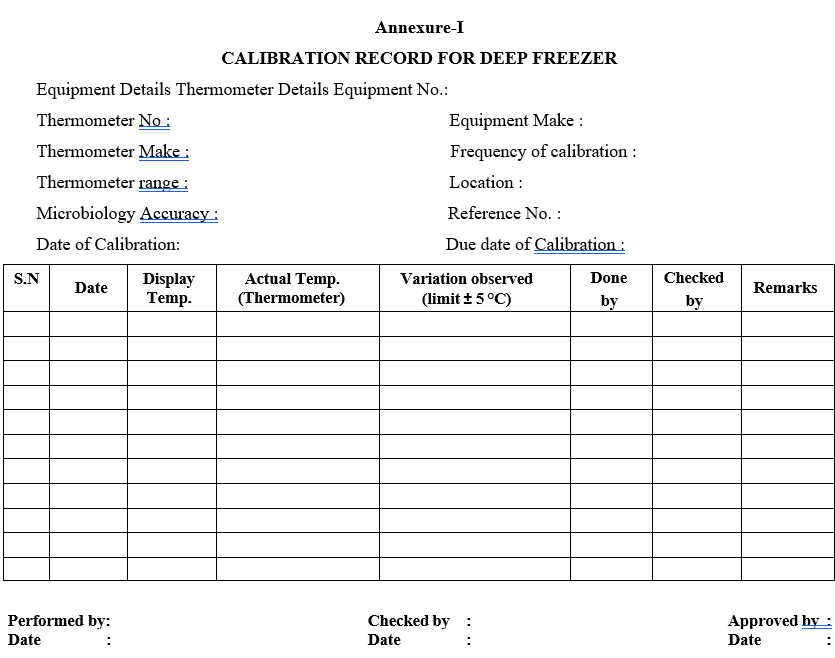

Maintain a Calibration Record for Deep freezer to note down the calibration result as per Format-I.

Temperature mapping procedure for Deep freezer:

Ensure that the preventive maintenance activity prior to temperature mapping of the freezer. (Performance qualification).

Temperature mapping shall be carried out for a period of 24 hours and the temperature shall be recorded at an interval of 15 minutes.

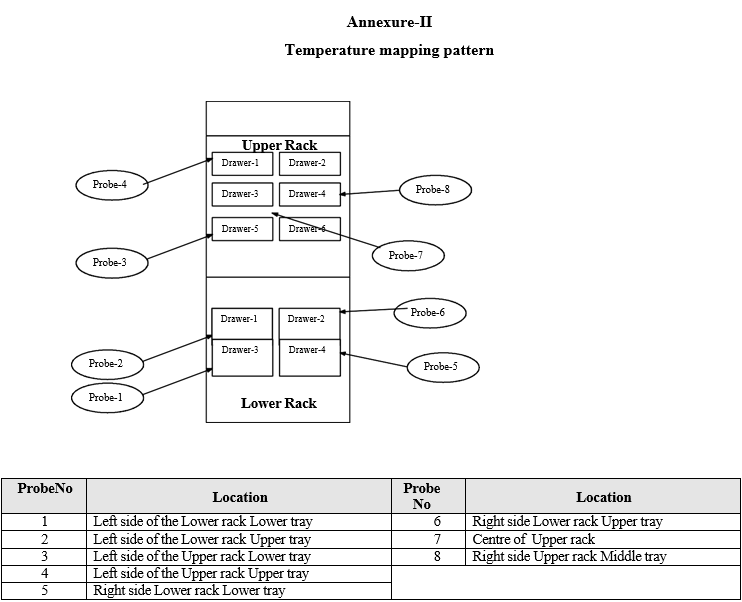

Temperature mapping shall be carried out with eight probes and the pattern shall be followed as per the format-2.

Select upper, and lower racks in the freezer.Ensure that the calibration status of each probe before starting the calibration.

Insert the probes (08 no’s) carefully in upper, and lower racks without disturbing the cultures/ samples.

Temperature mapping shall be carried once in year by placing the probes in the upper and lower racks, when in operation as a part of instrument performance check.

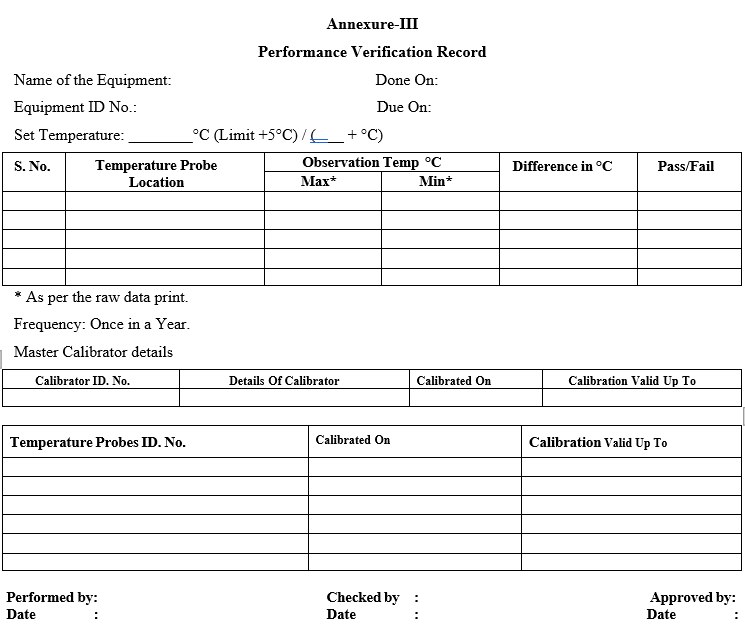

The maximum and minimum reading shall be recorded from the raw data (Data logging print out) in the Format-II.

Channels shall be labelled to each probe. Note: For temperature mapping pattern, refer format-II.

A variation of ± 5 °C is accepted between calibrated thermometer / probe and freezer display temperature.

If any discrepancy is observed during calibration, inform to the In-charge Quality Control and Maintenance Department for further corrective action.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/calibration-and-temperature-mapping-of-deep-freezer/

REFERENCES:

Not Applicable

ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Calibration Record for Deep Freezer |

| Annexure-II | Temperature mapping pattern |

| Annexure-III | Performance Verification Record |

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

Master Copy : Quality Assurance Department

Controlled Copy No. 01 : Head Quality Assurance

Controlled Copy No. 02 : Head Quality Control (Micro.)

ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

CALIBRATION RECORD FOR DEEP FREEZER

Annexure-II

Temperature mapping pattern

Annexure-III

Performance Verification Record

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/calibration-and-temperature-mapping-of-deep-freezer/