- PROCEDURE:

- Flame Sensitivity and Precision Calibration

- Operate the instrument as per the SOP.

- Install copper HCl lamp in position (1-4) of the instrument.

- Click on the File then open method, in the open method window click on “FL Sen & Prec” Method or Browse for the method.

- Select the Lamp setup from the tools and switch on the Cu Lamp and allow the lamp to warm up for 30minutes then close the lamp setup window.

- From the Tools pull down menu open the windows Continuous graphics and flame control.

- Align the burner head parallel to the beam as described in the operational SOP and make sure the burner head is level.

- Make sure the burner head is not blocking the beam, and auto zero in the continues Graphics window.

- Click on align burner in the flame control window.

- Select automatically align the burner, then click on the forward button and follow the Instructions in the wizard boxes.

- At the end of the procedure store the found positions.

- Keep the flame onAspirate the copper standard and slowly turn the nebulizer adjustment nut counter clockwise Until you see bubbles in the Cu solution or until ABS goes to zero.

- Then turn the nebulizer adjustment nut clockwise until the absorbance goes to maximum and begins to decrease.

- The minimum acceptable value is ≥0.250Abs.Close the continues graphics window.

- The flame control window will remain open.

- In the tools pull down menu click on manual Analysis control and then on Results to open the windows.

- Aspirate the deionized water and in the manual analysis window click on Analyze Blank.

- 10 Replicates will be measured and an auto zero will be performed.

- Aspirate the 5mg/L Cu standard and in the manual Analysis window click on Analyze Standard.

- 10 replicates will be measured and a calibration curve will be generated.

- Click on Results press print command for report.

- In the results window check the values for the mean absorbance ≥0.250 and RSD≤0.3% and record the results in of calibration record.Aspirate DI water for at least 5 minutes.

- In the flame control window click on the Flame on/Off icon to turn off the flame and then close all windows.

- Chromium Characteristic Mass and Precision (THGA):

- Operate the instrument as per the SOP.

- Install the Chromium lamp in the lamps compartment (position 1 to 4).

- Click on the File then open method, in the open method window click on “THGA Cr” Method or Browse for the method.

- Select the Lamp set up from the tools pull down menu.

- Switch on the Cr lamp and allow warming up for 30 minutes.

- Close the Lamp setup window. From the tools pull down menu open the following Windows; Results, Transient peaks Display and automated analysis control.

- Before starting the test, run at least one dry firing without any sample to make sure that there is no residual signal (less than 0.005 integrated absorbance) from any previous injections or tube contamination.

- Load the Furnace Auto sampler with Cr (10ug/L or 10ppb) standard in appropriate location.

- Change all Defined to locations and type the sample location in the set up page of the automated analysis window.

- Click on the analyze tab and then on the analyze samples button to measure five 20ul Injections of the Cr standard.

- Calculate the characteristic mass using the characteristic mass tool from the Analysis pull down menu.

- The Characteristic mass (m0) results in pg and calculated from the mean integrated Absorbance (peak area) values should lie within 5.5pg±1.5pg.

- The RSD of the mean sample solution reading calculated from the integrated absorbance (Peak area) values for Cr must not exceed the maximum value of 2.0%.

- Click on Results and press print command for Report.

- Record the results in Format of calibration record.

- Auto sampler Linearity:

- Operate the instrument as per the SOP.

- Install the Cr Lamp in the in the lamps compartment (position 1 to 4).

- Click on the File then open method, in the open method window click on “THGA AS-800 Lin” or Browse for the method and edit the furnace program as below remaining defaults parameters shall be used.

- Furnace program

| Step | Temp (°C) | Ramp time | Hold time | Internal flow | Gas type |

| 1 | 110 | 1 | 30 | 250 | Normal |

| 2 | 130 | 15 | 30 | 250 | Normal |

| 3 | 1500 | 10 | 20 | 250 | Normal |

| 4 | 2300 | 0 | 5 | 0 | Normal |

| 5 | 2450 | 1 | 3 | 250 | Normal |

- Select the lamp set up from the tools pull down menu.

- Load the Furnace Auto sampler with Cr (10ug/L or 10PPB) standard in appropriate location.

- Change the Lamp set up window, from the tools pull down menu open the Windows, Results, Transiant peaks display, Calibration display and Automated Analysis.

- Change all Defined to locations and type the sample location in the set up page of the automated analysis window.

- Click on the Analyze tab of the Automated Analysis window and then on the Calibrate Button to start the calibration.

- Auto sampler injects the Cr standard volumes at 5ul, 10ul, 15ul and 20ul with 3 replicates.

- The Average value of each volume will be considered for the calibration.

- When the calibration is finished check the Correlation Coefficient in the Calibration Display window.

- Click on Results and press print command for report.

- The correlation Coefficient Result for Cr must be equal or not to exceed the minimum Value of 0.996.

- Record the results in Format of calibration record.

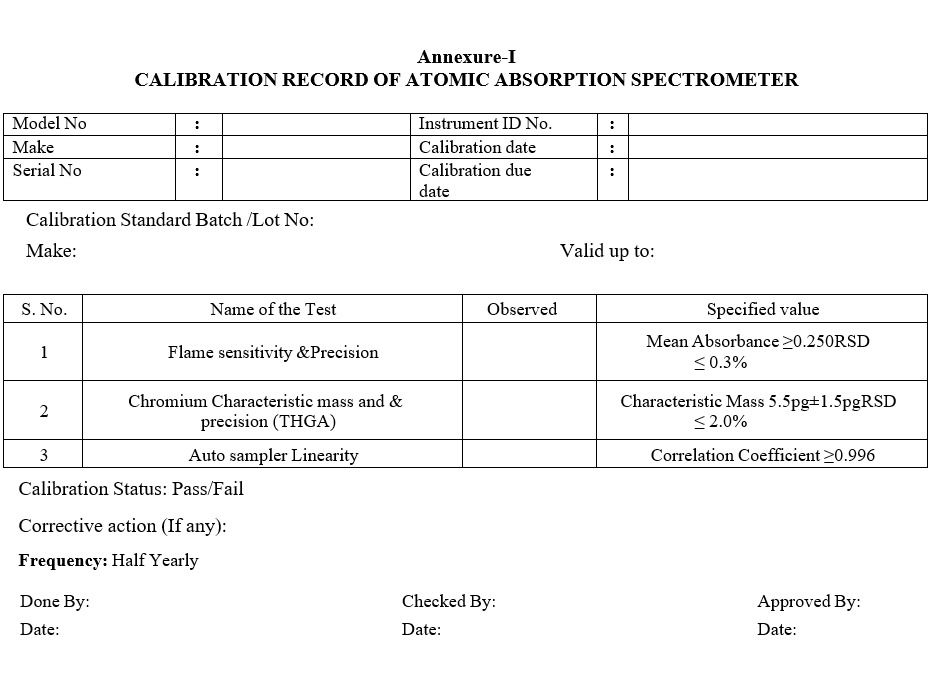

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Calibration Record of Atomic Absorption Spectrometer |

Annexure-I

CALIBRATION RECORD OF ATOMIC ABSORPTION SPECTROMETER