OBJECTIVE:

To lay down a procedure for Calibration of Differential Pressure Switch.

SCOPE:

This SOP is applicable to the procedure for Calibration of Differential Pressure Switch at {Company Name} {Location}.

RESPONSIBILITY:

Officer/Executive/Designee: shall be responsible for following the procedure as per SOP.

Engineering Head/designee is responsible for compliance of SOP.

ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

PROCEDURE:

Ensure that the Standard Digital Multifunction Calibrator (MC5) is in cleaned condition.

Ensure that the Standard Digital Multifunction Calibrator (MC5) is within the validity period.

Ensure that the Standard Digital Multi function Calibrator (MC5) is in charged condition.

Ensure that the switch, which is to be calibrated, is externally clean.

Follow the procedure of SOP Calibration of Equipments/Instruments before and after completion of the Calibration activity.

Calibration frequency shall be followed for Differential Pressure Switch as per the master calibration schedule.

Calibration of Differential Pressure Switch:

Switch ON the Multifunction calibrator by pressing On/Off key.

Under calibrating Differential pressure switch Negative terminal port is always open.

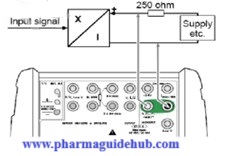

Connect the pressure pump to both the Multifunction calibrator port INT20c and positive terminal port of the under calibrating Differential pressure switch.

If using External pressure measurement module EXT400mC and the EXT communication cable that Connects to MC5 external pressure module port.

Other end of the External pressure module EXT400mC to be connects “T” hosepipe connector.

Use low pressure measurement tube by using proper adopter and connect it to the pump.

Be sure that all the output connectors are properly plugged and connected to an instrument to avoid leakage.

Connect the MC5 to Differential Pressure Switch terminals Using MC5 as a HART Communicator.

Set the cut off point for Differential pressure switch.

Ensure that the pressure release valve is closed (turn fully clock wise, but keep in mind that excessive force may damage the seals).

Operate the main piston Handle several times to raise the pressure and close to the required valve.

Observe the differential pressure switch NO/NC contact points through MC5 HART function Communication.

If required pressure increase or decrease by using fine control adjustment with the variable volume.

Check the differential pressure switch cut-off points 1 or 2 observe the reading and note down the readings in Calibration certificate Format-I.

The acceptance criteria for Differential Pressure Switches are +/-2% of span, if the least count of the switches is more than the above said acceptance criteria then its least count shall be taken as acceptance criteria.

Sign off the calibration certificate by the respective person.

File the approved Calibration Certificate with Calibration Lab.

Based on the Calibration results prepare the Calibration status label.

Affix/tag the Calibration status label as per the SOP.

REFERENCES:

Not Applicable

ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Calibration Certificate for Differential Pressure Switch |

DISTRIBUTION:

Controlled Copy No. 01 : Head Quality Assurance

Controlled Copy No. 02 : Head Engineering

Master Copy : Quality Assurance Department

ABBREVIATIONS:

| No. | : | Number |

| HART | : | Highway addressable remote transducer |

| MC5 | : | Multifunction calibrator |

| DP | : | Differential pressure |

| SOP | : | Standard Operating Procedure |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable |

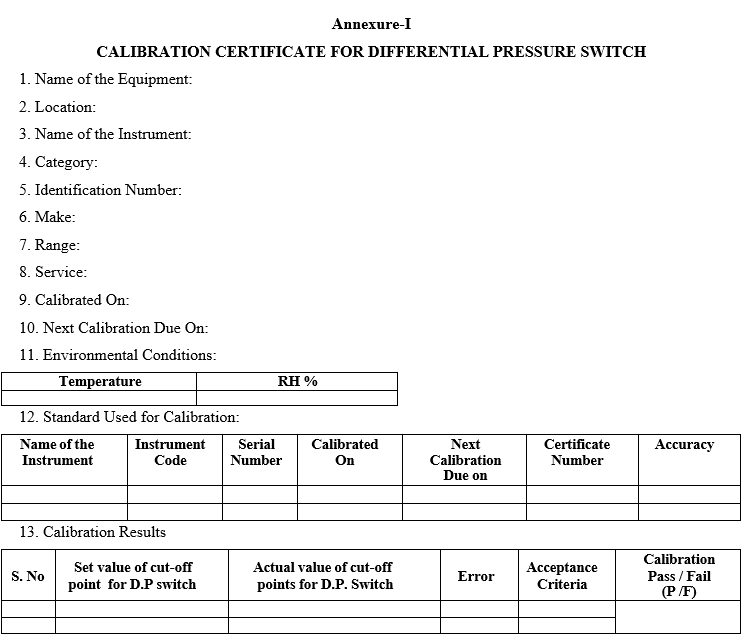

Annexure-I

CALIBRATION CERTIFICATE FOR DIFFERENTIAL PRESSURE SWITCH