OBJECTIVE:

To lay down a procedure for Calibration of Calibration of Master clock and Master Hand Held Calibrator.

SCOPE:

This SOP is applicable to the procedure for Calibration of Calibration of Master clock and Master Hand Held Calibrator at {Company Name} {Location}.

RESPONSIBILITY:

Officer/Executive/Designee: shall be responsible for following the procedure as per SOP.

Engineering Head/designee is responsible for compliance of SOP.

ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

Master Clock and Importance:

In the pharmaceutical industry, a Master Clock is a highly accurate timekeeping device that serves as the primary reference for time synchronization across the entire facility. It ensures that all clocks and time-dependent equipment within the plant are operating on the same, precise time. This is crucial for various reasons:

Importance of Master Clock in Pharma:

Regulatory Compliance:

Pharmaceutical manufacturing is heavily regulated by agencies like the FDA and EMA. These regulations often have strict requirements for accurate timekeeping to ensure product quality, safety, and traceability.

Time-stamped records, such as batch records, equipment logs, and environmental monitoring data, must be accurate to meet regulatory standards.

Quality Assurance:

Precise timekeeping is essential for maintaining product quality and consistency. It helps in tracking critical parameters like temperature, humidity, and pressure, which can impact product stability and efficacy.

Time-sensitive processes, such as sterilization and incubation, rely on accurate timing to ensure desired outcomes.

Data Integrity:

Accurate timekeeping is crucial for data integrity. It helps in identifying trends, anomalies, and potential issues in real-time.

Time-stamped data can be used for troubleshooting, root cause analysis, and continuous improvement.

Security and Access Control:

Time-based access control systems rely on accurate timekeeping to ensure authorized personnel can access specific areas at designated times.

PROCEDURE:

Ensure that the Master Clock and Master Hand Held Calibrator is in cleaned condition.

All the slave clocks are allotted and maintained identification number as per the Format-I.

Master clock and Master Hand Held Calibrator Calibration shall be performed once in a year and as and when required.

Master clock and Master Hand Held Calibrator Shall be coded as per the SOP.

Ensure that the Master clock is calibrating by using www.time.nist.gov web site.

Calibration of Master clock:

Take the PC/Laptop to the master clock area to perform the online calibration.

Switch ON the PC/Laptop and provide the appropriate user name and password.

Wait till stabilization of the system after completion of the Virus test.

Select “START” and go to “CONTROL PANEL”.

Select “DATE AND TIME OPTION” in the “CONTROL PANEL”.

Select Internet time option and find the

- time.windows.com

- time.nist.gov.

In server option select time.nist.gov and click apply and then OK.

Cross check the master clock time with the internet time for the duration of 16 Hrs. and record the timings for every 2 hrs. as per Format-II.

After completion of master clock calibration cross check the slave clocks at random places for confirming the same time by using mobile communication.

After completion of random verification of slave clocks, affix the label to slave clocks as per format-IV.

As being slave clock receives the synchronized calibrated signal from the master clock continuously, there is no need for individual calibration for slave clocks.

Update and affix the Calibration status label for master clock as per the SOP.

If any problem with the digital wall clock is observed by the respective user department, they shall raise breakdown request as per the SOP.

If needs any replacement of the slave digital wall clock, new one shall be calibrated with master clock and record the readings as per Format-III.

Calibration of Master Hand held calibrator (GPS Transmitter):

Take the Hand held Master clock (GPS Transmitter) to open environmental area.

Press the calibrator push button, then switch ON the ON/OFF switch, releases the calibrator push button immediately.

Wait for few minutes till the master calibrator shows the calibrated time. To calibrated faulty time showing slave clock, then press the transmitter button of hand held master clock.

Faulty slave clock is automatically calibrated and shows the hand held master clock time.

Numbering of Digital Wall clocks (SLAVE)

Digital Wall clock code consists of 11 characters.

Example: DWCA0001-01 denotes 1st Digital wall clock in Production / warehouse block.

The first three characters are abbreviated for the instrument as DWC is Digital wall clock.

Fourth character indicates the Area/block/location of the Wall clock.

Fifth to eighth characters are unique serial number.

9th character is represents its “-“(hyphen).

10th and 11th characters denote serial number of replacement instrument.

Example: DWCA0001-02 represents second replacement of digital wall clock in production/warehouse block.

Format-I will be updated when the new digital wall clock assigned in list.

If any replacement of clock will be occurred at any time, that particular clock numbering will be given here under.

REFERENCES:

Not Applicable

ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | List of Digital Wall clocks (Slaves) |

| Annexure-II | Calibration/Verification Record for Master Clock |

| Annexure-III | Calibration/Verification Record for Slave Clock |

| Annexure-IV | Digital wall clock (slave) verification- Label |

DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Engineering

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| GPS | : | Global Positioning System |

| PC | : | Personal Computer. |

| SOP | : | Standard Operating Procedure |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

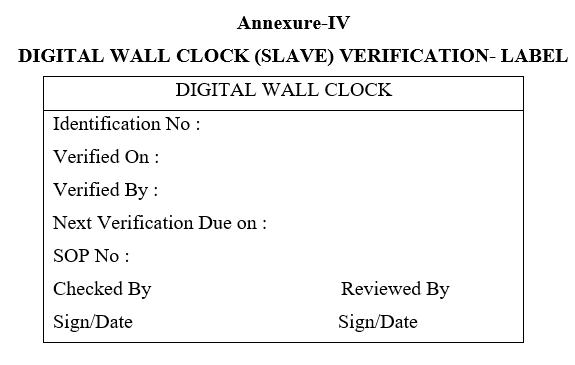

Annexure-I

LIST OF DIGITAL WALL CLOCKS (SLAVES)

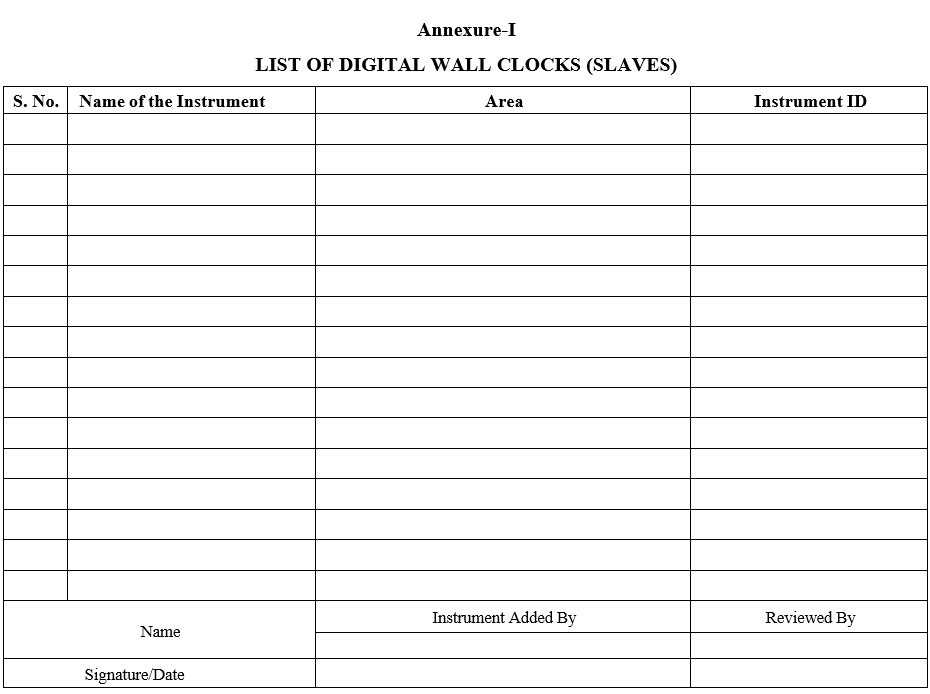

Annexure-II

CALIBRATION / VERIFICATION RECORD FOR MASTER CLOCK

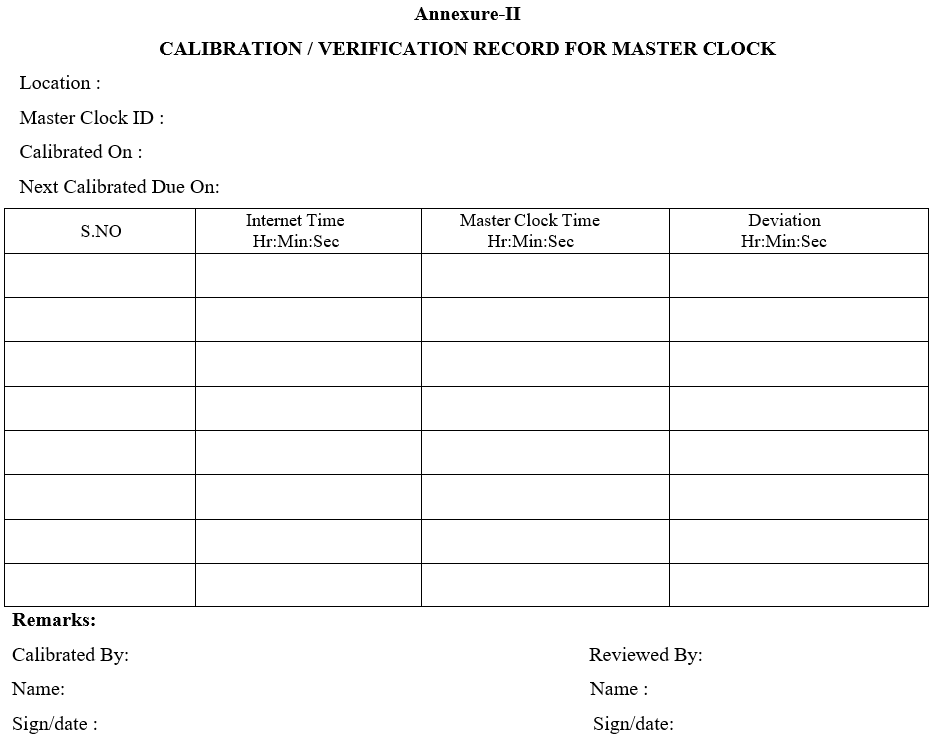

Annexure-III

CALIBRATION / VERIFICATION RECORD FOR SLAVE CLOCK

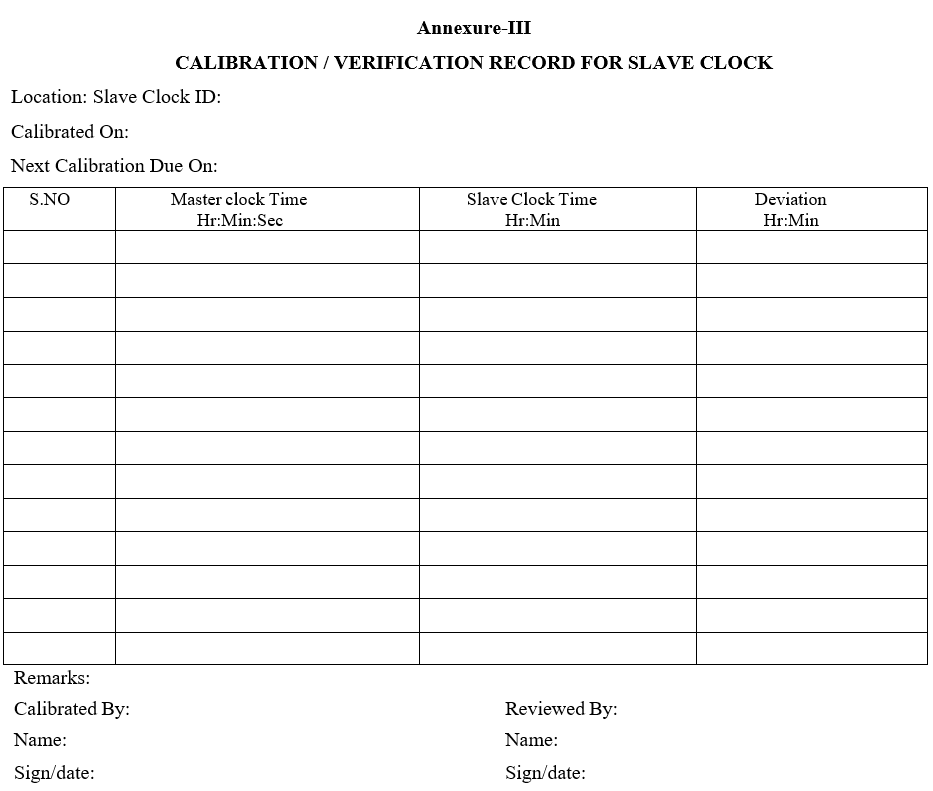

Annexure-IV

DIGITAL WALL CLOCK (SLAVE) VERIFICATION- LABEL