- OBJECTIVE:

To lay down the procedure for Calibration of muffle furnace.

- SCOPE:

This SOP is applicable to the procedure for Calibration of muffle furnace at {Company Name} {Location}.

- RESPONSIBILITY:

- Executive/Designee Quality Control is responsible to calibrate the instrument as per SOP.

- Head QC: Ensure the compliance of SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

- Muffle furnaces are incredibly versatile pieces of equipment used to generate high temperatures in a controlled environment.

- Operate the instrument as per SOP.Set the temperature to 600°C, 800°C & 1000°C by pressing `▲` or `▼`, wait until the temperature is stable and measure the temperature with calibrated thermocouple.

- Note down the observed readings in calibration record as per Format-I.

- The tolerance limit is ± 25°C from the set temperature.

- If the calibration is not proper report the results to the department head for taking an appropriate action.

- Frequency of Calibration: Half yearly.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/calibration-of-muffle-furnace/

- REFERENCES:

Not Applicable

- ANNEXURES:

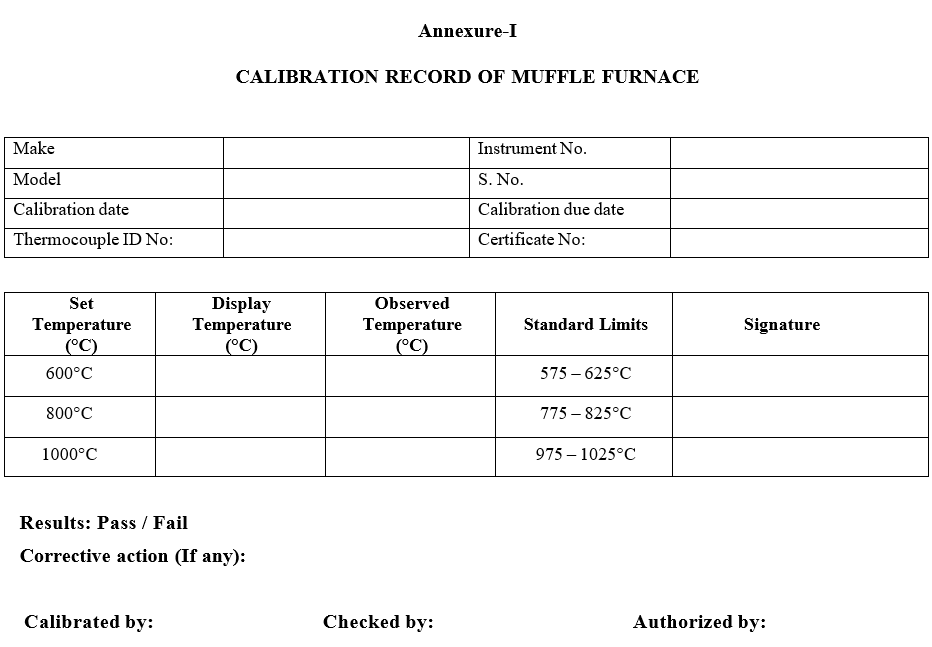

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Calibration record of Muffle furnace |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Quality Control

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

CALIBRATION RECORD OF MUFFLE FURNACE

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/calibration-of-muffle-furnace/