- OBJECTIVE:

- To lay down the procedure for Calibration of Tap density apparatus.

- SCOPE:

- This SOP is applicable to the procedure for Calibration of Tap density apparatus at {Company Name} {Location}.

- RESPONSIBILITY:

- Executive/Designee Quality Control is responsible to calibrate the instrument as per SOP.

- Head QC: Ensure the compliance of SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

- Before switching on the instrument, check the area and instrument cleanliness.

- Connect the plug to the power supply and switch on the power.

- Operate the instrument as per SOP.

- The following parameters to be calibrated for Tap density apparatus:

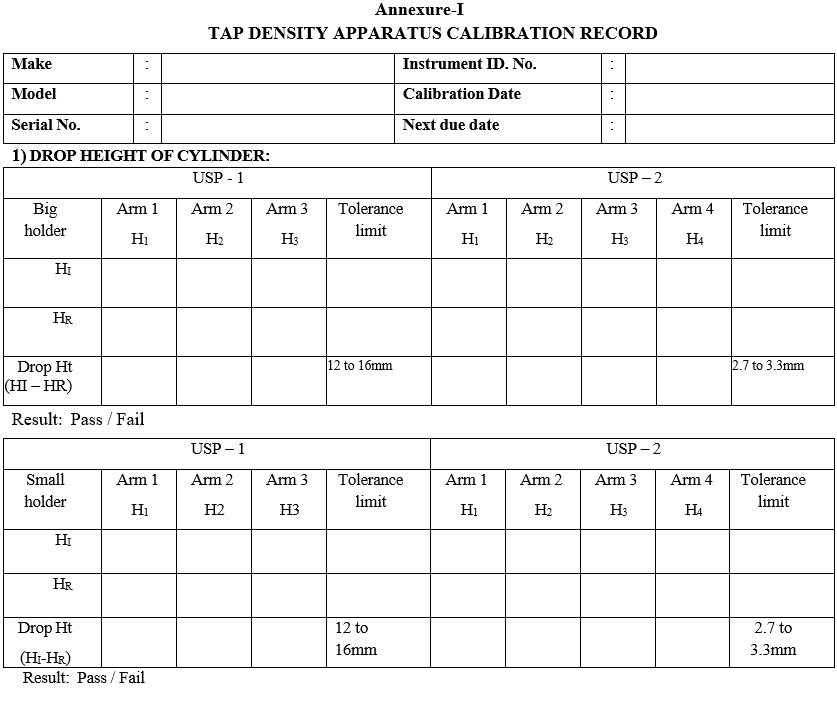

- Drop height of cylinder holder by using digital vernier caliper

- Number of drops per minute by using stopwatch

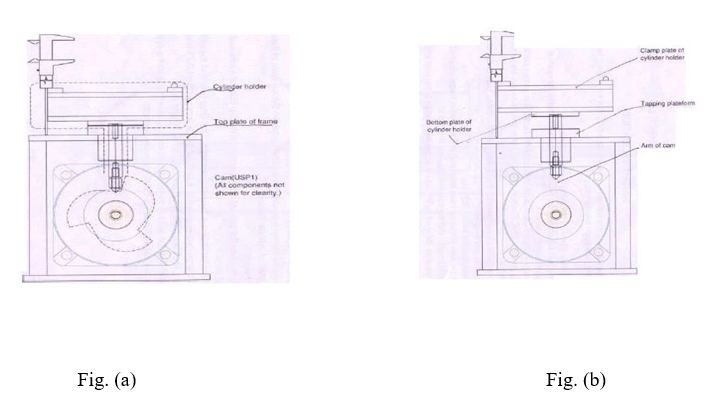

- Calibration of Drop height of cylinder holder for USP method 1:

- Open the top cover by removing bottom screws.

- Turn the cam attached to the motor shaft clock wise, so that the cylinder holder shaft is at the minimum position.

- Make sure that the bottom plate of the cylinder holder is in perfect contact with the tapping platform.

- Measure the distance between the top plate of frame and the clamp plate of cylinder holder by using digital vernier caliper; this reading is the base height (HR) as shown in figure (a).

- Rotate the cam further by hand, clockwise till the cylinder holder shaft reaches maximum height.

- At this position the shaft tip should be on the falling edge of the cam arm. Mark this arm No; 1 as shown in figure (b).

- Measure the distance between the top plate of frame and clamp plate of cylinder holder by using digital vernier caliper. This is height HI.

- Calibration of Drop height of cylinder holder for USP method 1:

- Make a mark on the point of measurement on the top plate of frame and on the cylinder plate.

- The difference between these two readings is drop height of the cylinder.

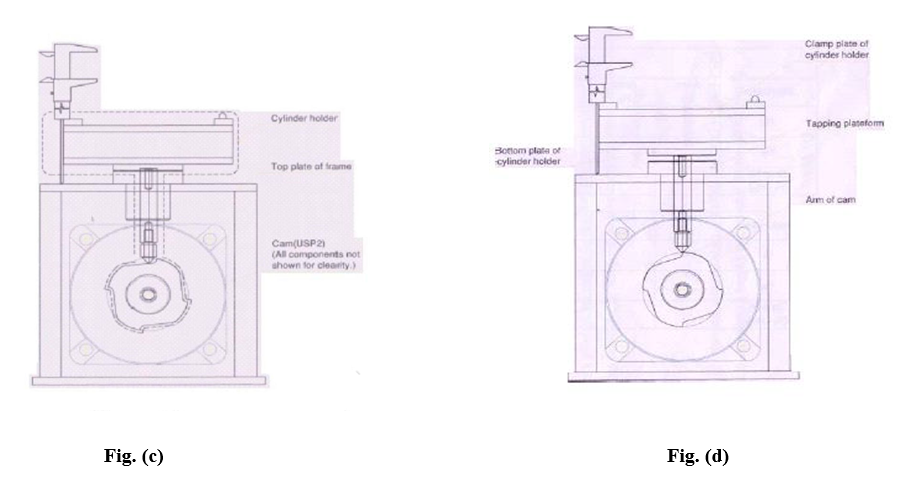

- Mark arms 1, 2 and 3 and heights H1, H2, H3 and so on. Repeat the above procedure for all arms with both cylinder holders.

- Make sure that the point of measurement on the top plate of frame and on the cylinder holder plate is maintained the same for all measurements.

- Record the results in the calibration format as per Format-I.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/calibration-of-tap-density-apparatus/

- Repeat the same procedure for all arms with both cylinder holder (figure c) and record the results in the calibration format.

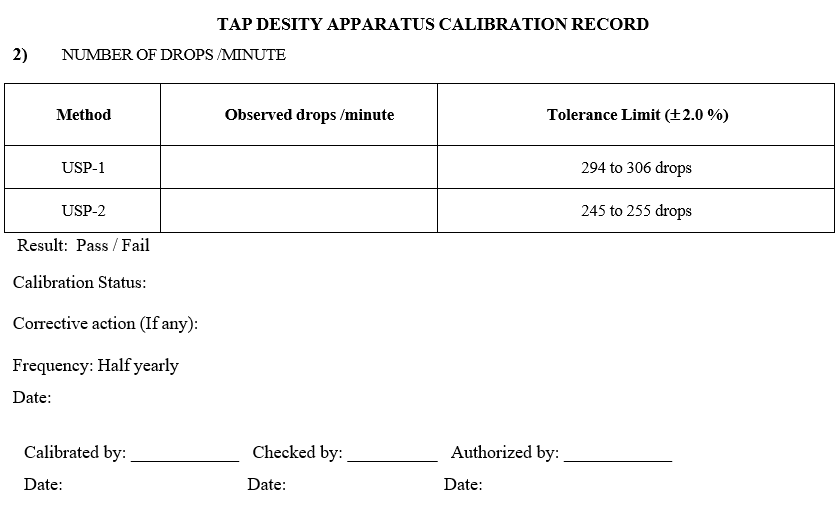

- Calibration for Number of drops of cylinder holder per minute:

- Choose the mode menu to ‘USP1’ by using digital scroll key.

- Press set key, set taps count to 300.

- Press start key to start the tapping and start the stop watch.

- Stop the stop watch after 1 Minute and note down the number of drops.

- The number of taps should be 300 ± 6.

- Similarly choose the mode menu to ‘USP11’ by using digital scroll key.

- Press set key, set taps count to 250.

- Press start key to start the tapping and start the stop watch.

- Stop the stop watch after 1 Minute and note down the number of drops.

- The number of drops should be 250 ± 5.

- Calibration for Number of drops of cylinder holder per minute:

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Tap density apparatus Calibration Record |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Quality Control

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

TAP DENSITY APPARATUS CALIBRATION RECORD

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/calibration-of-tap-density-apparatus/