- OBJECTIVE:

- To lay down the procedure for Calibration of UV- cabinet.

- SCOPE:

This SOP is applicable to the procedure for Calibration of UV- cabinet at {Company Name} {Location}.

- RESPONSIBILITY:

- Executive/Designee Quality Control is responsible to calibrate the instrument as per SOP.

- Head QC: Ensure the compliance of SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

- Calibration Procedure:

- Preparation of Alcohol (Ethanol 96%): Dilute 48 ml of Ethanol absolute (Not less than 99.5%) to 50 ml with purified water.

- Weigh accurately about 10mg of Sodium salicylate into a 25 ml volumetric flask, add 10 ml Ethanol (96 %) to dissolve and dilute the volume with the same (0.04%).

- Apply 5 ml of the above solution to Silica gel G coated plate.

- Place plate in cabinet and switch on the short wavelength (254 nm) and examine the spot in a position normal to the radiation.

- At the maximum intensity at about 254 nm, the standard spot of Sodium salicylate with a diameter of about 5 mm on chromatographic plate shall be revealed.

- Weigh accurately about 20 mg of Sodium salicylate in 10 ml volumetric flask, add 5 ml of ethanol (96%) to dissolve and dilute the volume with the same (0.2%).

- Apply 5 ml of the above solution to Silica gel G coated plate.

- Place plate in cabinet and switch on the long wavelength (365 nm) and examine the spot in a position normal to the radiation.

- At the maximum intensity at about 365 nm, the standard spot of Sodium salicylate with a diameter of about 5mm on chromatographic plate shall be revealed.

- Enter the results in calibration record as per Format-I.

- Frequency: Quarterly.

- Calibration Procedure:

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/calibration-of-uv-cabinet/

- REFERENCES:

British Pharmacopeia

European Pharmacopeia

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Calibration record for UV Cabinet |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Quality Control

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| UV | : | Ultraviolet |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

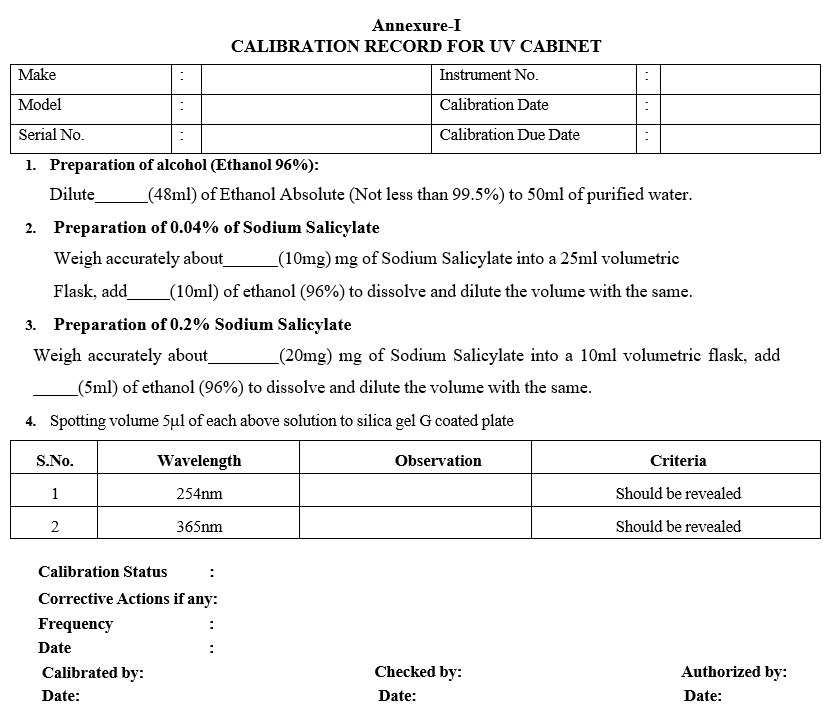

Annexure-I

CALIBRATION RECORD FOR UV CABINET

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/calibration-of-uv-cabinet/