- OBJECTIVE:

- To lay down the procedure for Calibration of Vacuum Oven, Make: Newtronic.

- SCOPE:

This SOP is applicable to the procedure for Calibration of Vacuum Oven at {Company Name} {Location}.

- RESPONSIBILITY:

- Executive/Designee Quality Control is responsible to calibrate the instrument as per SOP.

- Head QC: Ensure the compliance of SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

A vacuum oven is a specialized oven that removes moisture and other gases from a substance by creating a low-pressure environment inside the chamber. This is different from a standard oven, which uses heat and air circulation to dry materials.

- Operate the instrument as per SOP.

- Set the temperature controller knob to 60°C.

- After the set temperature is attained, measure it with a calibrated thermometer.

- The observed temperature should be within ± 2.0°C.

- Similarly perform the test at 100°C and 150°C and measure the temperature with a calibrated thermometer.

- The observed temperature should be within ± 2.0°C.

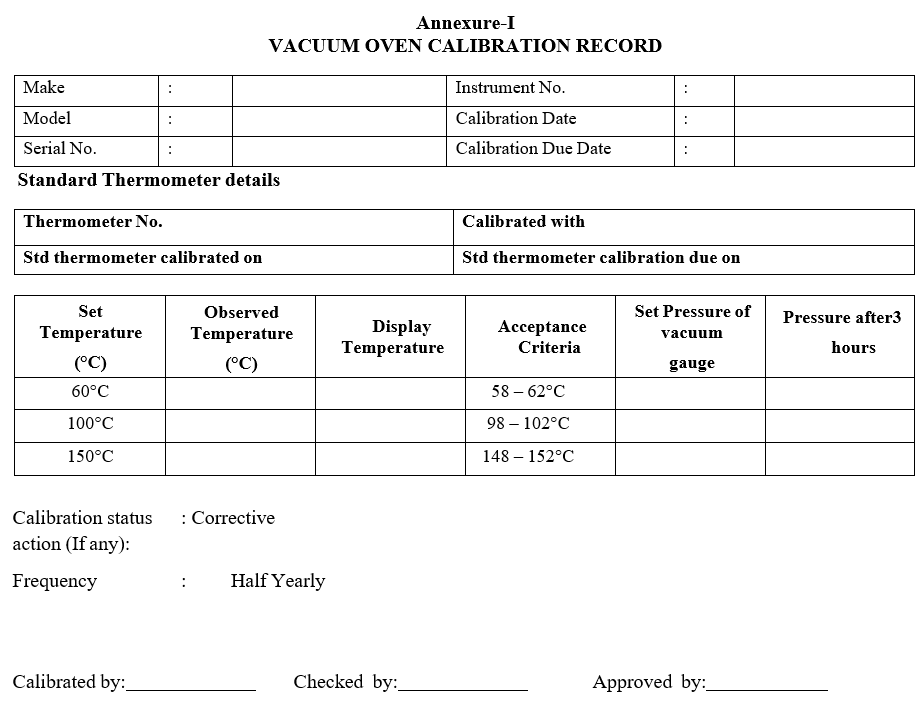

- Record the readings in vacuum oven calibration record as per Format-I.

- Create a vacuum of 400 mm and close the valve and observe the Vacuum drop for 3 hours. The Vacuum drop should be not more than 1.0% of the initial Pressure after 3 hours.

- The frequency for calibration of vacuum oven is Six months.

- If the calibration is not proper, report the results to the departmental head for taking an appropriate action.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/calibration-of-vacuum-oven-make-newtronic/

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Vacuum Oven Calibration record |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Quality Control

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

VACUUM OVEN CALIBRATION RECORD

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/calibration-of-vacuum-oven-make-newtronic/