- OBJECTIVE:

To describe a standard operating procedure for controlling of chemical material spillages at the workplace to minimize effects to the Environment, Health, and Safety due to chemical spills.

- SCOPE:

his Procedure is applicable to controlling of chemical material spillages at the workplace to minimize effects to Environment, Health, and Safety due to chemical spills at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Self-Inspection coordinator In charge – user department.

- In charge – EHS

- ACCOUNTABILITY:

QA Manager shall be accountable for Approval & Implementation of SOP.

- PROCEDURE:

Minor spill: A minor spill is one that usually presents little or no hazard to person or property and is safely cleaned up using the emergency spill kit.

Major spill: A major spill is one that poses immediate risk to health or involves fire or explosion.

- Handling Spills/ leaks:

- Initially stop the source of leakage/ Spillage.

- Identify the kind of material involved to control spill as per the MSDS instructions.

- If the spill does not involve any immediate risk to health, then below steps shall be followed:

- Immediately dike the spill to prevent spreading.

- Contain the spill with the help of sorbent pads, chemical resistant spill collection pan by using scoop/ mug or cleaning wiper based on the kind of spill as per the items available in spill control kit and if required cover the spill with sand. Also prevent the material from entering into drains.

- While controlling of spill, use suitable Personal Protective Equipment of Respiratory protection, Gloves, Face, and eye protection. Also based on the severity of spill, wear chemical resistant suit.

- The other necessary items available in spill kit are as mentioned below in spill kit items and shall be used based on the kind of spill.

- If the spill is meant for neutralizing, then get it neutralized by soda acid powder by using scoop and clean the surface by wiper and collect the spilled material into zipper bags. If the spilled material is able to collect in liquid form, then collect the same with the help of syphoning and shovel the mixture into the container and sent to Environment dept., for further disposal. Also, the other necessary items mentioned in spill kit shall be used based on the quality of material spilled (Refer MSDS).

- The used Personal Protective Equipment shall be discarded and handed over to Environment dept.

- If the Spill poses an immediate danger to health and involves fire/explosion, then follow below steps:

- Raise the fire alarm.

- Evacuate the area and restrict access.

- In the event of fire follows the fire plan and shut off all ignition sources.

- Try to control the spread of spills if safe to do so and seek external assistance.

- Consider accident investigation and consider measures to prevent reoccurrence.

- Chemical exposure to operating personnel:

- If any chemical exposure to operating personnel, then immediately flush with water under the shower in the area of contact based on the chemical involved or as per the instructions given in MSDS for a particular chemical.

- First-aid shall be given to victims as per instructions in MSDS. Remove the contaminated clothing if spilled on skin, wear clean clothes, and seek medical attention immediately.

- If the person inhales the chemical, then immediately remove victim to fresh air and seek medical attention immediately.

- Handling of Spill Control Kit:

- Spill control kit location must be easy accessible at respective work areas.

- Spill control kit shall be periodically checked once a month by the safety department and replenished after each use.

- There must be at least one spill control kit in spare other than the kits provided at different areas which is for emergency use.

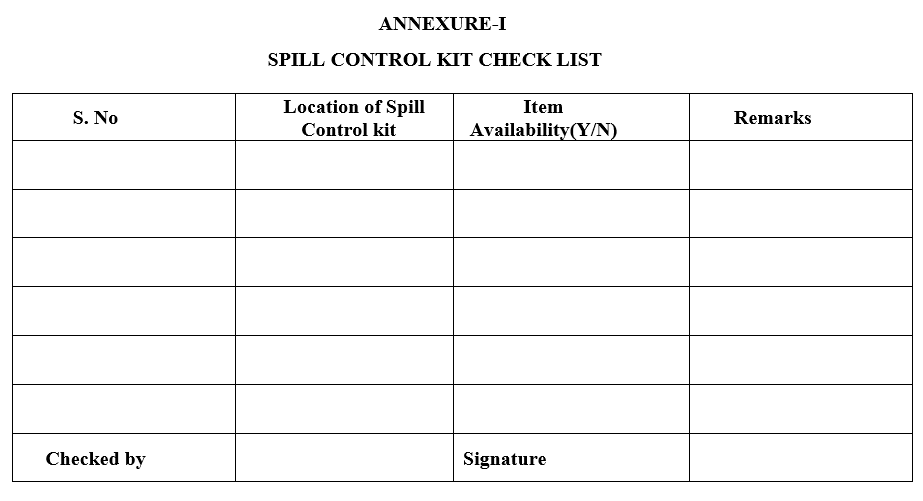

- Spill Control kit must be checked once in a month and record the status in the Template Annexure-I.This is updating through QA and no need to change control updating for location only DMS upload required.

- The following items in the table as given below must contain in Spill control kit:

| S. No. | Items Name | No. of Items |

| Chemical Sorbent 3M ,(PAD / SHEET TYPE) | ||

| Chemical Sorbent 3M ,(ROLL TYPE) | ||

| Chemical Resistant Booms | ||

| Oil Resistant Powder sorbent pads big size | ||

| Universal sorbent pads small size | ||

| Thick polythene bag for collection of Spills | ||

| Zipper bags for Collection of Spills | ||

| Scoop White & Blue | ||

| Chemical Resistant Spill Collecting Pan | ||

| Siphons | ||

| Mug White & Blue | ||

| Water absorption foam | ||

| Soda acid powder | ||

| Cleaning wiper | ||

| Chemical Resistant suit |

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Spill Control kit Check list |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

| Controlled Copy No. 01 | : | Safety Health & Environment |

| Master Copy | : | Quality Assurance Department |

- ABBREVIATIONS:

| EHS | : | Environment Health and Safety. |

| SOP MSDS ETP | : : : | Standard Operating Procedure Material Safety Data Sheet Effluent Treatment Plant |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

SPILL CONTROL KIT CHECK LIST

Frequently Asked Question?

- Q: What defines a minor spill?

- A: Little to no hazard, cleaned with the emergency spill kit.

- Q: What defines a major spill?

- A: Immediate health risk, fire/explosion hazard.

- Q: What’s the first step in handling a spill?

- A: Stop the source of the leak/spill.

- Q: How do you identify the appropriate response based on the material?

- A: Refer to the Material Safety Data Sheet (MSDS) for instructions.

- Q: What steps are taken for non-hazardous spills?

- A: Dike, contain with sorbent pads/pans, use PPE, and dispose of collected material per MSDS.

- Q: What steps are taken for hazardous spills?

- A: Raise the alarm, evacuate and restrict access, follow fire plan if needed, seek external help, and consider prevention measures.

- Q: What’s the immediate action for chemical contact?

- A: Flush with water based on the chemical or MSDS instructions.

- Q: What first-aid steps follow chemical exposure?

- A: Follow MSDS instructions, remove contaminated clothing, and seek medical attention.

- Q: What if someone inhales a chemical?

- A: Move them to fresh air and seek medical attention immediately.

- Q: Where should spill kits be located?

- A: Easily accessible in respective work areas.

- Q: How often are spill kits checked and restocked?

- A: Monthly by the safety department, and replenished after each use.

- Q: How many spare spill kits are required?

- A: At least one, separate from area-specific kits.

- Q: How is spill kit status monitored?

- A: Monthly checks recorded in a template (no further control updates needed, only location updates needed for DMS upload).

- Q: What items should be included in a spill kit?

- A: See provided list of sorbents, booms, pans, bags, scoops, wipes, and other essentials.