OBJECTIVE:

To lay down the procedure for cleaning and disinfection of drains.

SCOPE:

This SOP is applicable to the procedure for cleaning and disinfection of drains at {Company Name} {Location}.

RESPONSIBILITY:

- HR Executive/Designee – is responsible to follow the procedure as per SOP.

- Housekeeping: is responsible for cleaning.

- Head HR – is responsible for compliance of the SOP.

ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

Importance of drain cleaning and disinfectant:

Process area drains in pharmaceutical manufacturing are critical in maintaining aseptic conditions. To prevent contamination, these drains must be meticulously cleaned and disinfected. This involves removing debris and organic matter using detergents and sanitizers. Subsequently, drains are disinfected with chemical agents to kill microorganisms. Drain traps are also cleaned and filled with disinfectant solutions to prevent bacterial growth. Regular inspection and maintenance are crucial to ensure the effectiveness of these procedures and uphold the high standards of pharmaceutical production.

PROCEDURE:

Open the Drain cover scoop out any adhering solid material using a long handled scoop. Dispose the solid waste in a Polybags and clean it with 2% Teepol soap solution in purified water.

Flush the drain with purified water initially followed by 5.0 liters of 2% daily use disinfectant solution used on daily basis.

Allow it to stand for 15 minutes.

Flush out the drain point with sufficient amount of water.

Flush off the daily use disinfectant solution

Drains cleaning details shall be recorded in the given Format-I.

Cover the drain points with drain cover provided.

Records will be checked by supervisor Housekeeping and verified by Executive / area In charge.

All the drain points shall be covered after cleaning.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-and-disinfection-of-process-area-drains/

Frequency of Cleaning and Disinfection: once in a day/whenever required.

DISINFECTANT SOLUTIONS PREPARE REQUIRED DILUTIONS:

| S No. | Dates | Name of the Disinfectant | Concentr ation | Dilution (Disinfectant Solution Qty.) | Purified water Qty. | Prepared disinfectant solution Qty. | Remarks |

| 1 | 1st Week | Bacillocid special -2% v/v | 2% | 200 Ml | 9.800 Ltr. | 10 Ltr. | Process areas |

| 2 | 2nd Week | Sokrena -2% v/v | 2% | 200 Ml | 9.800 Ltr. | 10 Ltr. | Process areas |

| 3 | 3rd Week | Korsolex rapid-2% | 2% | 200 Ml | 9.800 Ltr. | 10 Ltr. | Process areas |

| 4 | 4th Week | Bacillocid special -2% v/v | 2% | 200 Ml | 9.800 Ltr. | 10 Ltr. | Process areas |

| 5 | 5th Week | Sokrena -2% v/v | 2% | 200 Ml | 9.800 Ltr. | 10 Ltr. | Process areas |

| 6 | All weeks | Teepol – 2%v/v | 2% | 200 Ml | 9.800 Ltr. | 10 Ltr. | Process areas |

Location of Drain points:

| DRAIN POINT LOCATIONS | |||

| S.No | Room No | Room Name | Drain Point Number |

| 1 | COATING | ||

| 2 | WASH AREA | ||

| 3 | GRANUALATION | ||

| 4 | BLENDING | ||

| 5 | DISPENSING | ||

REFERENCES:

Not Applicable

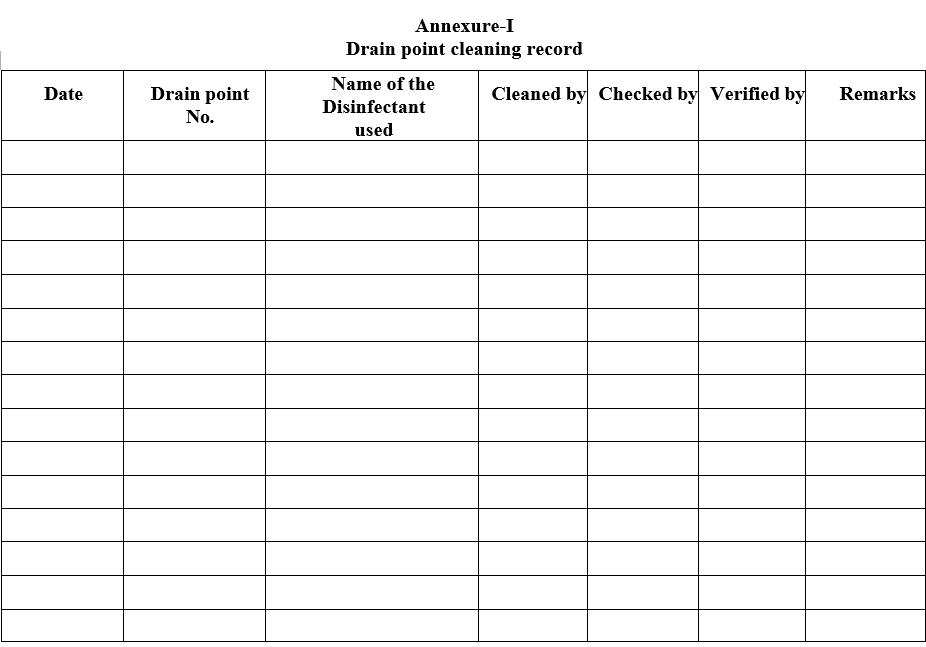

ANNEXURES:

| Annexure No. | Title of annexure |

| Annexure-I | Drain point cleaning record |

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Human resources

- Master Copy : Quality Assurance Department

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-and-disinfection-of-process-area-drains/

ABBREVIATIONS:

| HR | : | Human resources |

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| IPA | : | Iso Propyl Alcohol. |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

Drain point cleaning record

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-and-disinfection-of-process-area-drains/