- OBJECTIVE:

To lay down a procedure for cleaning and replacement of CFL and tube lights in the Production, Packing, Warehouse, Quality assurance, Quality control laboratory and Engineering areas.

- SCOPE:

This SOP is applicable for cleaning and replacement of CFL and tube lights in the Production, Packing, Warehouse, Quality assurance, Quality control laboratory and Engineering areas at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering is responsible to perform the activity as per the SOP.

- Head / In charge – Engineering is responsible to ensure the compliance as per the SOP.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- Switch OFF the power supply of respective light fixture.

- Remove the bottom cover of Light fixture.

- Remove the old lamps from the lamp holder and clean the lamps with dry cloth.

- Clean the light fixture frame with vacuum cleaner.

- Clean the acrylic sheet with dry cloth.

- Refix the cleaned lamps and bottom cover.

- Check and ensure the working condition of the light fixture, if required replace with new lamps and record the same in the Annexure-I.

- The frequency for cleaning and replacement of lamps is half yearly or whenever is necessary.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-and-replacement-of-cfl-and-tube-lights/

- REFERENCES:

Not Applicable

- ANNEXURES:

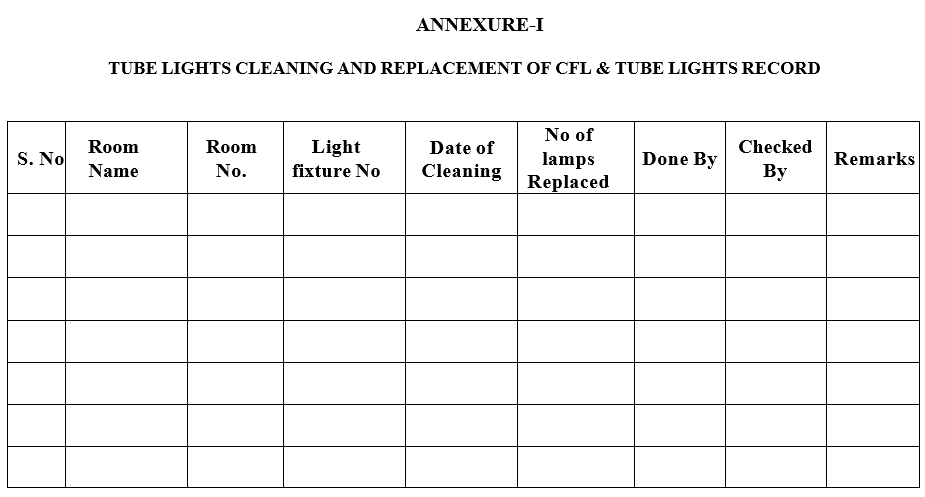

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Tube Lights Cleaning and Replacement of CFL & Tube Lights Record |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

SOP : Standard Operating Procedure.

CFL : Compact Fluorescent Light.

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

TUBELIGHTSCLEANINGANDREPLACEMENTOFCFL&TUBELIGHTSRECORD

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-and-replacement-of-cfl-and-tube-lights/