- PROCEDURE FOR THE CLEANING OF OCTAGONAL BLENDER:

- Size of Blender: 150/300 ltrs & 600 Liters

- An octagonal blender is a type of industrial mixer specifically designed for the gentle and efficient mixing of dry, free-flowing materials, particularly in the form of granules or powders .

- TYPE “A” CLEANING:

- Ensure that the status label shall be updated as “TO BE CLEANED”.

- Ensure that the mains to the machine area switched off before cleaning.

- Remove labels, materials and containers of previous batch from the blending area.

- Remove all the adhered material from the outer surface of the octagonal blender and unit using vacuum cleaner, wipe with dry lint free cloth.

- Open the rectangular lid and wipe the inner surface of the blender shell with dry lint free cloth.

- Ensure that no adhering material will be seen on the surface of the blender shell and body of the blender.

- After completion of cleaning update, the status label as CLEANED.

- Record the cleaning details in the equipment logbook as per SOP.

- FREQUENCY: After every batch of the same product.

- TYPE “B” CLEANING:

- Ensure that status label shall be updated as “TO BE CLEANED”.

- Switch off the mains of octagonal blender and cover all the electrical points with polythene cover.

- Remove any material, labels and containers of previous product from the octagonal blender area.

- Dismantle the rectangular window lid with baffle by unclamping ring nuts using spanner.

CAUTION: While unbolting the lid make sure that, it is supported.

- Remove the gasket from the rectangular window and wipe with dry lint free cloth.

- Dismantle pneumatic butterfly valve from the blender by unclamp the TC clamp.

- Keep all dismantle parts on SS pallet, cover with polybag.

- Affixed the “TO BE CLEANED” label.Transfer the cleaned parts to the washing area for cleaning.

- CLEANING OF BLENDER SHELL AND AREA:

- Remove any adhering material from the octagonal blender using vacuum cleaner.

- Clean the blender shell of 600Ltrs with 100L of potable water by using nylon scrubber until no adherent material is seen.

- Clean the blender shell of 150 liters with 50Ltrs of potable water by using nylon scrubber to remove the adhering material.

- Clean the blender shell of 300Ltrs with 80Ltrs of potable water using nylon scrubber.

- Rinse the blender shell of 600 ltrs with 80L of potable water.

- Rinse the blender shell of 150/300ltrs with 30L of potable water.

- Finally rinse the octagonal blender shell of 600 ltrs with 50L of purified water.

- Finally rinse the octagonal blender shell of 150/300 ltrs with 30L of purified water.

- Wipe the blender shell with dry lint free cloth and allow to dry.

- Wipe the pillar and railing with wet lint free cloth dipped in potable water followed by wipe with lint free cloth dipped in purified water.

- Remove the polythene bag fixed to the electrical points and wipe them with dry lint free cloth.

- Wipe the control panel, blender frame with lint free cloth dipped in purified water followed by wipe with dry lint free cloth.

- Mop the area with disinfectant solution.

- CLEANING OF BUTTERFLY VALVE AND BAFFLE:

- Wash the dismantled parts with 80L of potable water by using nylon scrubber until no adherent material is seen.

- Rinse with the above parts with 50L of potable water.Finally rinse the parts with 50L of Purified water.

- Finally wipe the parts with dry lint free cloth and allow to dry.

- Rinse the gaskets with purified water and wipe with dry lint free cloth.

- Transfer the cleaned parts to blending area and assemble the dismantled parts in the reverse order of dismantling.

- Close all the open parts using stretch film.The status label shall be updated as “CLEANED”.

- NOTE: Care is to be taken so that no water enters in to the control panel and gearbox assembly.

- CLEANING OF SS BINS/CANISTERS:

- Wash the SS bins/Canisters with 50ltrs of potable water by using nylon scrubber. Again, rinse with sufficient quantity of potable water to the SS bins.

- Finally rinse the parts with 30Ltrs of purified water.

- Dry the SS bins by wipe with dry lint free cloth.

- The status label shall be updated as “CLEANED”.

- Record the cleaning details in the equipment logbook as per SOP.

- Finally wipe the blender shell with lint free cloth dipped in 70 % IPA.

- Remove the polythene bag fixed to the electrical points and wipe them with dry lint free cloth.

- Wipe the walls, Ceilings, doors, pendants and glass with lint free cloth. Mop the area with disinfectant solution.

- The status label shall be updated as “CLEANED”.

- Frequency: After every batch (For different strength), or after every 6 days (if continuous production of same product.

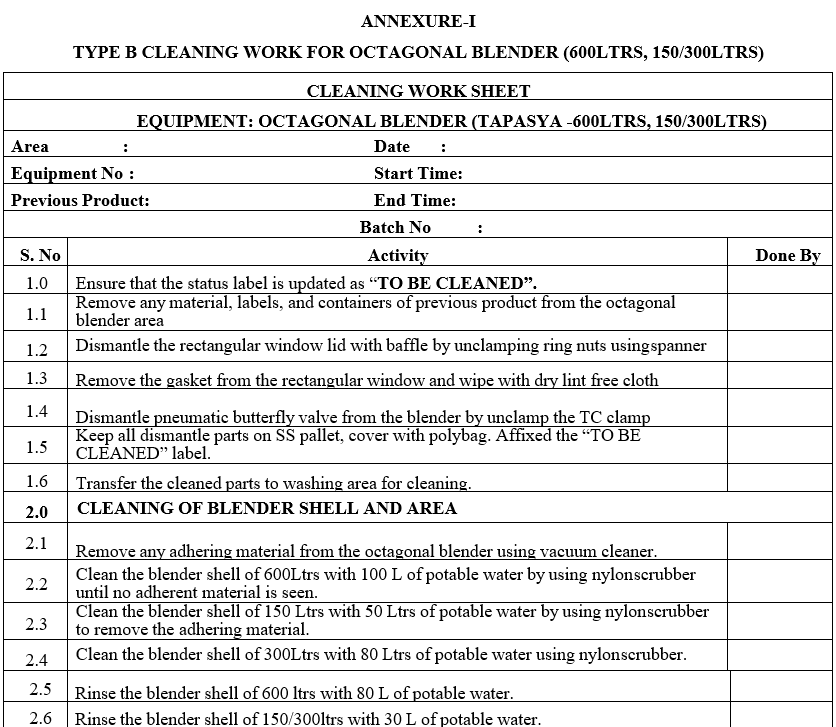

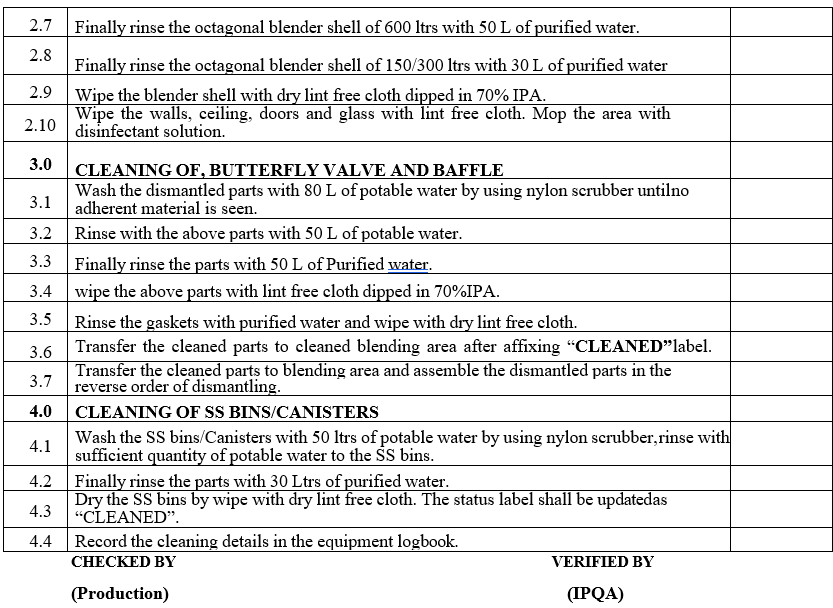

- ANNEXURES:

| ANNEXURE NO | TITLE OF ANNEXURE |

| Annexure-I | Type B cleaning Work for Octagonal Blender (Tapasya -600ltrs, 150/300ltrs) |

- ABBREVIATIONS:

| QA | : | Quality Assurance |

| SS | : | Stainless Steel |

| IPA | : | Isopropyl Alcohol |

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

ANNEXURE-I

TYPE B CLEANING WORK FOR OCTAGONAL BLENDER (600LTRS, 150/300LTRS)