- A Rapid Mixer Granulator (RMG), also known as a high shear mixer granulator, is a piece of equipment widely used in the pharmaceutical industry . It is used to mix pharmaceutical ingredients and create granules from them before they are compressed into tablets or capsules.

- CLEANING PROCEDURE FOR RAPID MIXER GRANULATOR :

- Make: Tapasya

- TYPE “A” CLEANING:

- Status label shall be updated as “TO BE CLEANED”. RMG mains shall be switched off before cleaning.

- Labels, materials and containers of previous batch shall be removed from the granulation area.

- Material adhered to the inner surface of the RMG shall be scraped by using Teflon Scrapper.

- Powder adhered to the outer surface of the RMG shall be removed by using vacuum cleaner.

- The outer surface of the RMG shall be wiped using dry lint free cloth. Update the status label as Cleaned and record the cleaning details in equipment logbook.

- Frequency: After every batch of the same product.

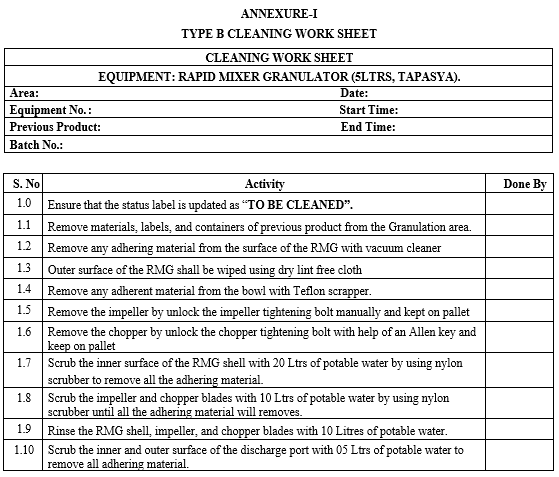

- TYPE “B” CLEANING:

- Status label shall be updated as “TO BE CLEANED”. Ensure that the mains are switched off before cleaning and cover all electrical points with polythene cover.

- Labels, materials and containers of previous batch shall be removed from the granulation area.

- Remove any adhering material from the surface of the RMG with vacuum cleaner. The outer surface of the RMG shall be wiped using dry lint free cloth.

- Ensure that the discharge valve shall be in open condition and place SS container below the discharge valve of the RMG.

- Remove any adhering material from the inner surface of the RMG using Teflon scrapper.

- Open the RMG top lid by unlock the bolt manually. Remove any adherent material from the bowl with Teflon scrapper.

- Remove the impeller by unlock the impeller tightening bolt manually and kept on the pallet.

- Remove the chopper by unlock the chopper tightening bolt with help of an Allen key and keep on pallet.

- Scrub the inner surface of the RMG shell with 20Ltrs of potable water by using nylon scrubber to remove all the adhering material.

- Scrub the impeller and chopper blades with 10Ltrs of potable water by using nylon scrubber until all the adhering material will removes.

- Rinse the RMG shell, impeller and chopper blades with 10 Litres of potable water.

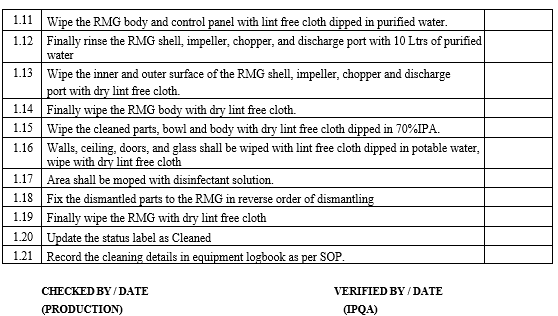

- Scrub the inner and outer surface of the discharge port with 5Ltrs of potable water to remove all adhering material. Wipe the RMG body and control panel with lint free cloth dipped in purified water.

- Finally rinse the RMG shell, impeller, chopper and discharge port with 10Ltrs of purified water.

- Wipe the inner and outer surface of the RMG shell, impeller, chopper and discharge port with dry lint free cloth.

- Finally wipe the RMG body with dry lint free cloth.

- Walls, ceiling, doors and glass shall be wiped with lint free cloth dipped in potable water, wipe with dry lint free cloth.

- Area shall be moped with disinfectant solution.

- Update the status label as Cleaned and record the cleaning details in equipment logbook.

- Note for Type B Cleaning:

- For Type B Cleaning first clean the equipment with lint free cloth then after clean with potable water. If needed the equipment surface can be rubbed with nylon brush or lint free cloth. If a product is not clean with water, then a cleaning agent can be added in potable water. Then after rinse with potable water and followed the rinsing of equipment with purified water. After rinsing equipment shall be dry with compressed air then wipe with lint free cloth. After drying the surface of equipment shall be wiped with 70% IPA.

- Frequency:

- After every batch of the same product from higher to lower strength and lower to higher strength.

- For Product-to-Product changeovers.

- Major breakdown of equipment.

- As when required.

- REFERENCES:

- Not Applicable

- ANNEXURES:

| ANNEXURE NO | TITLE OF ANNEXURE |

| Annexure-I | Type B cleaning Work Sheet |

- ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Production

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| QA | : | Quality Assurance |

| SS | : | Stainless Steel |

| IPA | : | Isopropyl Alcohol |

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

- REVISION HISTORY:

- CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

Annexure-I

TYPE B CLEANING WORK SHEET