- OBJECTIVE:

To lay down a procedure for Cleaning of RO Product Water Storage Tank.

- SCOPE:

This SOP is applicable for Cleaning of RO Product Water Storage Tank at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering is responsible to perform the Cleaning activity.

- Executive/ Manager – Engineering is responsible to ensure the compliance as per SOP.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- R O product water storage tank:

- DO NOT direct the water jet towards the unit itself, electrical Parts or towards other electrical equipment.

- DO NOT touch the connection plug and / or socket with wet hands.

- Take the cleaned HDPE tank with purified water (100 liters) and connect with jet cleaner pump before starting the cleaning.

- Turn OFF the RO system.

- Remove the top lid and vent filter from top of the tank.

- Open the drain valve of the tank and drain the water from the tank.

- Open the valve of purified water supply line to the pump from HDPE tank.

- Switch on the jet cleaner pump and then apply the high-pressure jet of purified water, keeping the nozzle at least 10 inches from the surface.

- Ensure the drain valve is kept open.

- Repeat the cleaning with 100 liters once again.

- Place the top lid and vent filter.

- Close the drain valve.

- Feed the water in the tank as usual by RO system in Auto mode.

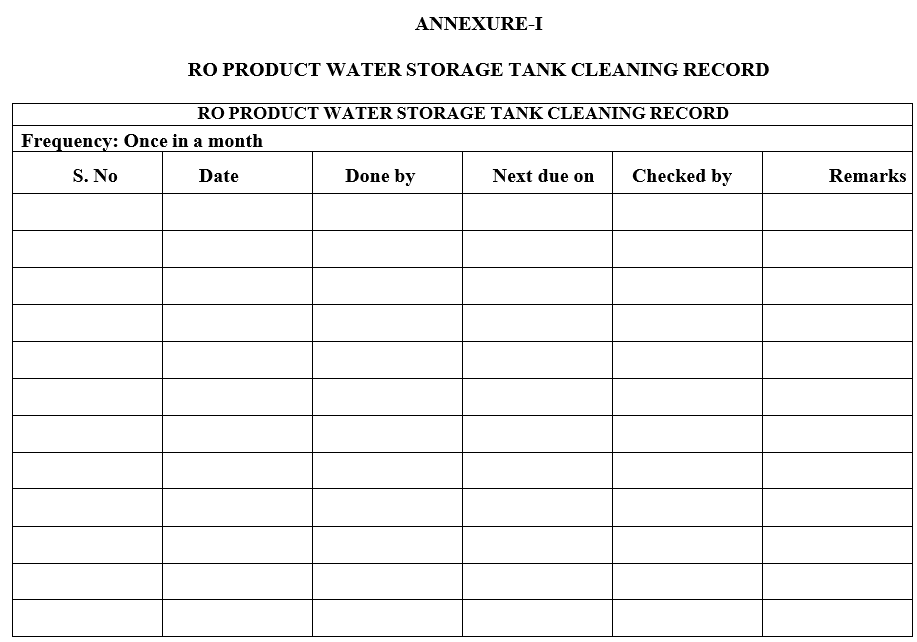

- Record the cleaning details as per Annexure-I.

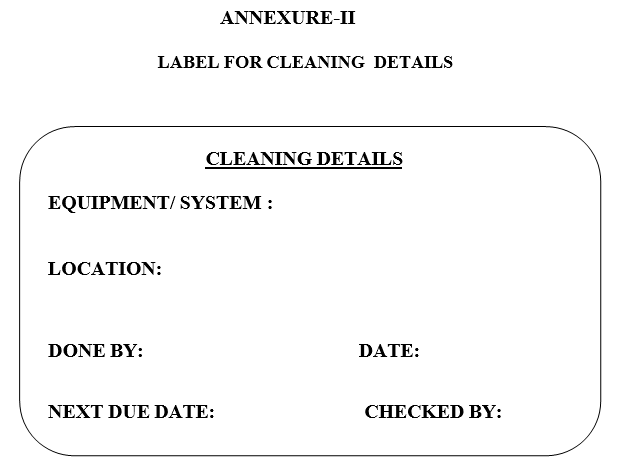

- After completion of the Cleaning, labels shall be updated on the tanks as per Annexure-II.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-procedure-for-ro-product-water-storage-tank/

- Frequency:

Cleaning shall be carried out once in a month along with every month first fortnightly preventive maintenance of purified water system.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | RO product water storage tank cleaning record |

| Annexure-II | Label for Cleaning Details |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

R O : Reverse Osmosis

HDPE : High Density Polyethylene

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

RO PRODUCT WATER STORAGE TANK CLEANING RECORD

ANNEXURE-II

LABEL FOR CLEANING DETAILS

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/cleaning-procedure-for-ro-product-water-storage-tank/