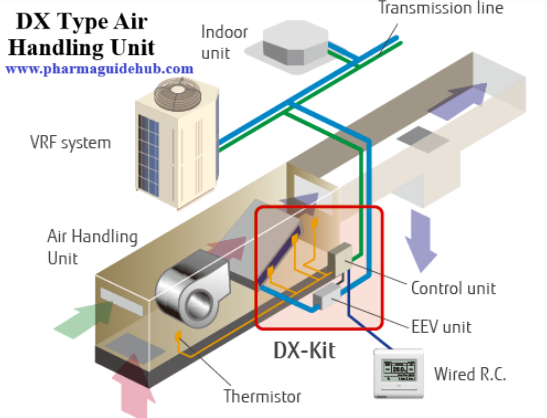

DX stands for Direct Expansion. In a DX type Air Handling Unit (AHU), the refrigerant directly cools or heats the air passing through the unit. This is achieved by passing the air over a coil where the refrigerant evaporates or condenses.

Key Components and Functions:

- Outdoor Unit: This unit houses the compressor, condenser, and expansion valve. It’s responsible for circulating the refrigerant and transferring heat to or from the outside environment.

- Indoor Unit (AHU): This unit contains the evaporator coil, fan, and filters. The air to be conditioned passes over the evaporator coil, where the refrigerant absorbs or releases heat, cooling or heating the air.

| Department: Engineering Equipment Name: DX type Air handling Unit Equip. No./ID: Frequency: Quarterly |

| S. No | Check Points | Procedure | Activity | Done By / Date |

| 1. | Check the AHU damper Position | By physical verification of the AHU damper as per standard marking. | ||

| 2. | Check the condition of the filter | By both the physical verification and verifying the differential pressures across the filter. If found filter chock clean with compressed air afterwards with water and dry in the drier. If still the differential pressure s are not within the limit, replace the filters. | ||

| 3. | Check the Motor and Blower pulleys | With the help of thread facing on the pulley face check the alignment of motor pulley and blower pulley if any clearance noticed adjust the pulleys equally in line. If pulleys observed damage then replace the same. | ||

| 4. | Check motor & blower base bolts. | Take the exact spanner of that specific bolt and nut for tighten the bolts. | ||

| 5. | Motor bearings and blower shaft bearings shall be checked | Physically observe for any abnormal sound and also observe the motor end covers for hot. If observed any of these abnormalities bearings shall be replaced | ||

| 6. | Check the V-belt condition | Check the V belt tension by pressing the belts together if found tight or elongation adjust the adjustable nuts on the motor base accordingly. If physical condition of the V-belt found brittle replace the belt. | ||

| 7. | Ensure the earthing of compressor unit and motor. | Check the Earthing wires for proper connections | ||

| 8. | Check the compressor and AHU Motor Voltage and Amperage. | By using a Clamp meter ensure that they are within the acceptable Limit with respect to motor rating. | ||

| 9. | Check the refrigeration gas | Open the dummy nut and connect the pressure gauge and ensure that the gas pressure should be 60psi at suction line in operation .if less than top up. | ||

| 10. | Check the copper joints | Take a soap solution and apply on the copper joints, if found any leakages then arrest the leaks or repair. | ||

| 11. | Check the DX Cooling coil circuit and condenser coil | By Physically verifying the coils and found dust clean with dry Cora cloth or with vacuum cleaner. | ||

| 12. | Check the cooling coil condensate tray. | By Physical verification of the cooling coil condensate tray and found tidy clean with cloth and if require clean with 40% Sodium Hypochlorite solution | ||

| 13. | Check & tighten the motor terminals, control wiring terminals, indication lamps and OLR setting | Physical verification and loosen wires shall be tightened with tester | ||

| Remarks: Checked By / Date | ||||