- OBJECTIVE:

To lay down the procedure for handling and Maintenance of Desiccator.

- SCOPE:

This SOP is applicable for the procedure for handling and maintenance of Desiccator at {Company Name} {Location}.

- RESPONSIBILITY:

- Officer/Executive/Designee Quality Control – Shall be responsible for following the procedure as per SOP.

- Head/Designee Quality Control – Shall be responsible for ensuring compliance as per SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

A desiccator is a sealed container used to create and maintain a dry environment for storing or drying sensitive items. It’s essentially a humidity-controlled box that prevents moisture from spoiling or damaging your materials.

- Remove all the materials from desiccator and keep the same in another desiccator. Remove the desiccant.

- Clean the desiccator with lint free cloth.

- Remove the desiccant and activate by drying at 150 degrees for 2 hours.

- Activate the desiccant frequently or monthly once.

- The Activation of details shall be recorded in a register, giving details of date, temperature, drying time, done by.

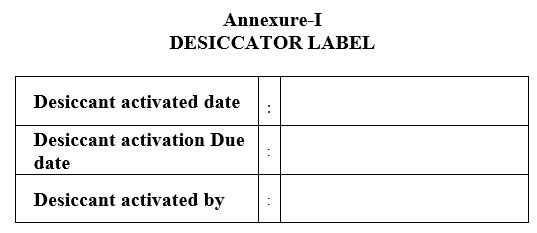

- The desiccator is affixed with a label giving details of desiccant activated date, desiccant activation Due date, desiccant activated by.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/handling-of-desiccator/

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Desiccator Label |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Quality Control

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

DESICCATOR LABEL

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/handling-of-desiccator/