OBJECTIVE:

To lay down the procedure for Laundering, Issue & Return of Uniforms.

SCOPE:

This SOP is applicable to the procedure for Laundering, Issue & Return of Uniforms at {Company Name} {Location}.

RESPONSIBILITY:

- All employees working on Premises is responsible to follow the procedure as per SOP.

- Head HR – is responsible for compliance of the SOP.

ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

Key Points of Procedure:

Laundering, issuing, and returning uniforms in the pharmaceutical industry is a critical aspect of maintaining a clean and controlled environment. Uniforms are rigorously laundered using specialized detergents and procedures to ensure the removal of contaminants and prevent cross-contamination. Issuance and return processes are strictly regulated to maintain traceability and accountability. Uniforms are often assigned to specific individuals, and their movement is tracked to ensure compliance with hygiene and quality standards. This meticulous management of uniforms plays a crucial role in safeguarding product quality and preventing potential contamination risks within pharmaceutical manufacturing facilities.

PROCEDURE:

Precautions:

Ensure that for washing machine inlet value is should not be in leakage position.

While starting the washing of garments the person concerned should wear gloves and disposal mask.

Check for the water inlet hose connection and do not leakage. Ensure that the uniform are sorted out in area wise and washed separately.

Remove uniforms from washing machine and dry immediately after the cycle is complete to avoid creasing.

Check the uniforms before ironing, if any mending work is required hand it over to Housekeeping supervisor for necessary rectification.

New factory uniforms, aprons, primary garments and secondary garments stitching frequency shall be done once in a year as per the schedule, and as and when required.

Employee code number shall be located on the collar of the shirt and belt area of the trouser for identification.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/laundering-issue-and-return-of-uniforms-in-pharma/

Equipments:

- Vertical Washing Machine – Make: Ramson- 35 kg capacity.

- Hydro Extractor – Make: Ramson – 30 kg capacity.

- Electrical Drier – Make: Ramson – 25 kg capacity.

- Electric Irons – For pressing the garments.

- Pressing tables

- Wet linen Trolley

- Soiled linen Trolley

- Racks for stacking the pressed garments

- Potable water Scoops.

- Measuring cylinder

- Plastic tubs

Washing machine cleaning procedure:

Clean the garment washing machine before carrying out the washing of garments as per the following procedure.

Open the inlet valve of the water to the machine, fill portable water in the washing chamber, Close the water inlet valve.

Put the cleaning agent Launders Render Wash washing powder 100 grams through in let, Set the cycle time for 10 minutes and switch on the washing machine.

The machine stops automatically after the set time cycle.Open the drain valve and drain out the detergent solution.

Open the inlet valve of the water again to fill potable water in the washing chamber for 200 Ltr approximately. Run the machine for 2 to 3 minutes and then drain the water.

Visually check the cleanliness of the machine. In case the cleanliness of the machine is not satisfactory, repeat the process if the cleanliness of the machine is satisfactory; proceed for the washing of garments as per the procedure mentioned below.

Laundry detergents:

Launders Rendet Wash washing powder – For washing of garments.

Launders EML -For removing stains from the garments.

Collection of Soiled Garments(primary):

Collect the soiled primary uniforms from change rooms separately department wise from the soiled linen bins in polythene bags.

Carry the collected soiled primary dresses in tied polythene bags to the Laundry.

Collection and detoxification of secondary garments (Protective suites/Booties):

Collect the secondary garments from the mist shower pass box in closed container.

Transfer the closed container in to laundry room.

Soak the garments in 5% sodium hydroxide solution and kept aside for 2 hours for detoxification.

After detoxification wash the secondary garments as mentioned above.

Preparation of 5% Sodium hydroxide solution:

Take 50grams of sodium hydroxide flaxes and dissolve in approximately 100ml of potable water and make the volume up to 1.0 liter with potable water in graduated measuring cylinder.

Prepare the required quantity of solution depends up on the garments to be detoxified.

Note: Primary uniforms & secondary uniforms, aprons shall be washed separately.

TABLE FOR NUMBER OF GARMENTS WASHED PER EACH LODE

| DESCRIPTION | NO. OF GARMENTS |

| Primary uniforms (trouser, shirt, cap) | 30 Pair |

| Secondary uniforms (Boilersuit with bootees and headgear) | 30 sets |

| Aprons | 30 No’s |

Procedure for Garment washing:

Open the door of the washing machine gently put the clothes piece by piece and then closes the door.

Load approximate 30 pairs of primary uniforms at a time in to the washing machine and take the potable water for 200 Ltr through inlet and set the timer 5 minutes and pre wash.

Pre wash according to the requirement once or twice.

After prewash, drain the water from the washing machine and fill potable water.

Add 200 grams cleaning agent Laundrex Rendet Wash washing powder (with help of scoop) and Laundrex EML stain remover 100 ml .(with help of measuring cylinder) through the inlet.

Set the timer to 20 minutes, switch on heater and set temperature to 50º – 60º.

Switch of the heaters after the temperature has been attained and after completing the first wash cycle for 20 minutes drain the water.

In the last rinse, fill fresh water and allow the machine to run for 3-5 minutes followed by draining off the water completely.

After completing the washing unload the garments in to a plastic tub (or) wet linen trolley and transfer to hydro extractor.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/laundering-issue-and-return-of-uniforms-in-pharma/

Hydro extractor operation:

Open the Hydro Extractor door. Load the garments from wet linen trolley into Hydro Extractor till it is full then Close the door and lock it.

Switch on the power on Machine control panel then switch on the Hydro Extractor Machine switch. Set the timer on 10 minutes. Press the start green colour switch.

After 10 minutes when the Machine switches off automatically press the Emergency stop red colour switch which will stop the Machine. After 5 minutes unlock and then open the door and unload the garments.

Tumbler drier operation:

Open the drier door gently Load the garments to 3/4 th volume of chamber and Close the door.

Switch on the power supply on control panel, Switch on the heater and leave for 30 min.

After 30 min when the machine beeps switch OFF the drier and open the door. Unload the garments into clean linen trolleys (or) polybag and keep near pressing tables for Ironing, (Ensure that the pressing tables covered with clean tablecloth).

Stack the pressed uniforms polythene covers in the racks colour wise.

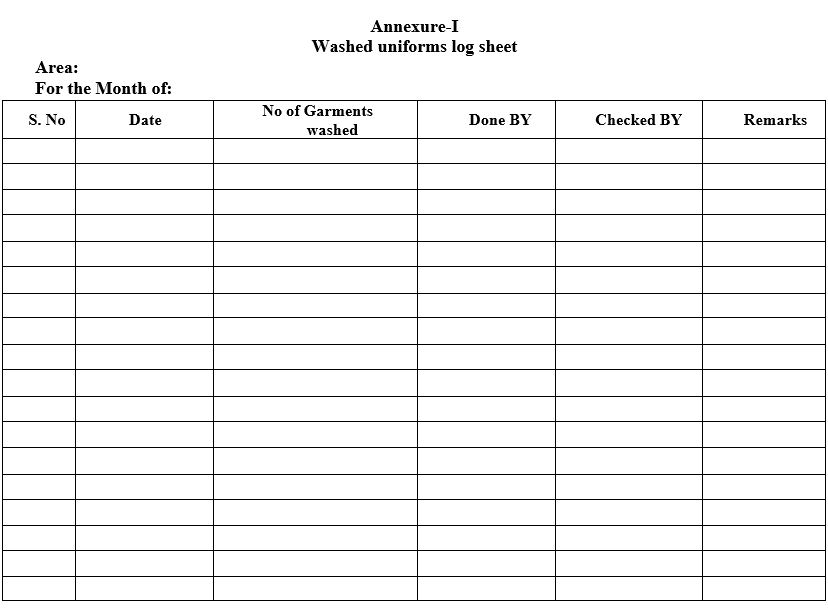

Enter the washed garments in details in Washed uniforms log sheet as per Annexure-I.

The cleaned garments shall be handled by using fresh hand gloves. Carry the ready linen to Linen room in closed polythene bags and stack it in racks as labelled.

Frequency of cleaning garments: Twice in a week and after every product changeover for primary garments & daily every shift for secondary garments.

Issue of clean Uniforms and Return of Soiled Uniforms:

Fresh uniforms are issued every Monday, Thursday for all departments and while the product change over in particular area.

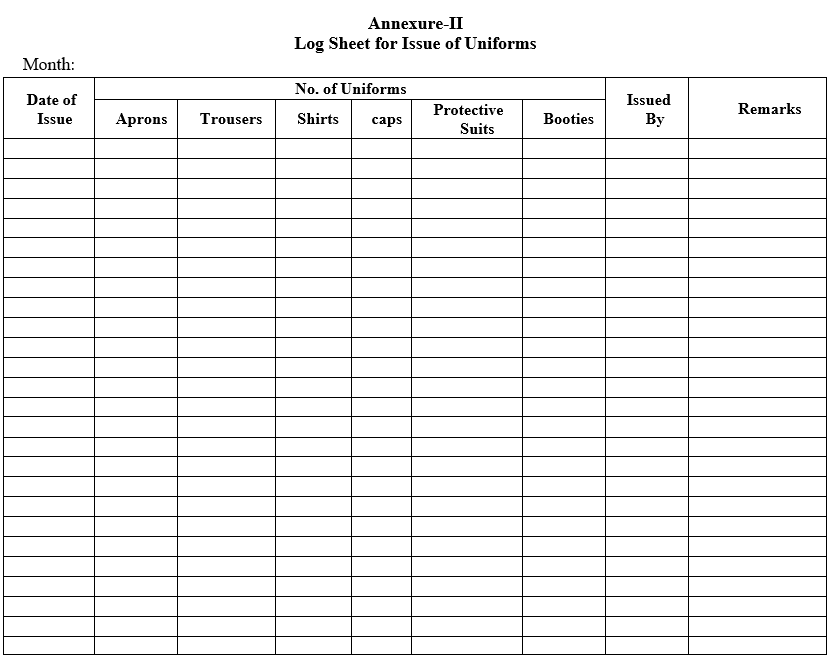

Issue of Uniform entries are noted down in log sheet are as per Annexure-II2.

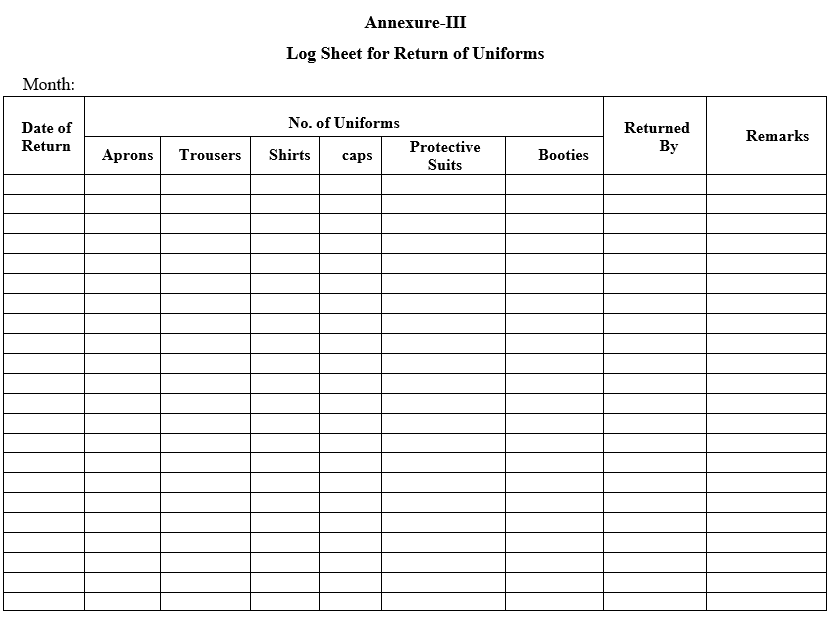

Used uniforms are returned back on every Monday, Thursday from all departments and while the product change over in particular area.

Return of used uniform from employees entries are noted down in a log sheet as per Format-III.

REFERENCES:

Not Applicable

ANNEXURES:

| Annexure No. | Title of annexure |

| Annexure-I | Washed uniforms log sheet |

| Annexure-II | Log Sheet For Issue of Uniforms |

| Annexure-III | Log Sheet For Return of Uniforms |

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

Master Copy : Quality Assurance Department

Controlled Copy No. 01 : Head Quality Assurance

Controlled Copy No. 02 : Head Human resources

ABBREVIATIONS:

| HR | : | Human resources |

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

Washed uniforms log sheet

Annexure-II

Log Sheet for Issue of Uniforms

Annexure-III

Log Sheet for Return of Uniforms

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/laundering-issue-and-return-of-uniforms-in-pharma/