OBJECTIVE:

To lay down a procedure for Lock out Tag out Try out (LOTOTO).

SCOPE:

This SOP is applicable for covers the servicing and maintenance of equipments in which the unexpected energizing or start-up of the equipments, could cause injury to employees and safety statement to protect all employees from the hazards by the safe method of locking and tagging of isolated equipments at {Company Name} {Location}.

RESPONSIBILITY:

Engineering/Safety Officer/Executive- Execution as per laid down procedure.

Engineering Head- Technical correction, review, training & monitoring of SOP.

ACCOUNTABILITY:

Engineering Head

Quality Assurance Head

PROCEDURE:

The Lock Out/Tag Out procedure prevents the unexpected start up or release of stored energy that could cause injury to employees by placing a lock and/or warning tag on an energy isolation device.

Lockout Tag out (LOTO) procedures ensures that the hazardous energy sources are isolated and rendered in-operable before any maintenance work commences.

A safety lock is used when the energy source is turned off to prevent it being switched on. Locking out refers to the physical method of isolating a piece of equipment or machinery to prevent it from releasing stored energy or potentially re-energizing while work is being done on it.

Tag out specifically refers to the visible written warning, on an attached tag or sign, that a piece of equipment is locked out and should therefore not be used.

It should be highly visible and obvious.

LOTOTO increasingly is being used to highlight the activity of attempting the re-energization of the locked out equipment to check that all is in order – prior to starting the work.

LOTOTO describes the Lockout, Tag out, Try-out steps where the formal addition would identify if there were any faults with the Isolation Point(s) where further work would be needed to address these prior to any planned work commencing.

A good example of this is a faulty rotary electrical isolator – it could be easily turned off and lockout out but remaining energized due to a common mechanical breakage of the isolator internals.

Sequence for Lock out Tag out Try out (LOTOTO):

The Lock-out, Tag-out, Try-out (LOTOTO) procedure has long been considered one of the safest ways to isolate equipment prior to maintenance work or repairs taking place.

The procedure is integral for protecting employees and outside contractors from accidental re-energization of equipment, and potential injury or fatalities.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/lock-out-tag-out-try-out-lototo/

The stages of LOTOTO and its importance within a health and safety strategy. With nine clearly defined steps, the procedure can be undertaken safely providing the correct lock-out equipment is used.

The stages of the procedure are as follows:

Prepare: Before the LOTOTO procedure can begin, a plan should be in place for the methods of control. The equipment should be fully assessed, and the correct lock-out materials selected. Workers within the area should be made aware that lock-out is occurring; this will help to prevent accidental re-energization.

Shut down: Prior to the LOTOTO procedure taking place, the necessary equipment must be correctly shut down. This should be in line with manufacturers’ instructions to ensure the safety of employees.

Equipment Isolation: The isolation points on the equipment should be identified and partnered with an appropriate lock-out device prior to installing the devices. This will ensure that all necessary energy sources have the correct lock-out equipment required for blocking the energy source. Both primary and secondary energy sources should be identified and isolated at this stage.

Begin Lock out: The lock-out devices should now be applied to fully isolate the equipment. The apparatus used as part of the LOTOTO procedure, such as safety padlocks from Reece Safety and identification tags, should be unique to the person applying them, and not be used for any other workplace activities. Storing lock-out equipment within a dedicated station will ensure they remain safe and accounted for. Once the devices have been safely applied, each should be carefully tagged. The tags will act as an identifier for the person who applied them, with information such as their name, picture and date and time of application on them. As a lock-out device should not be removed by any person other than those who applied them, the tags will ensure identification which will prevent removal and accidental restarting of the equipment by someone else.

Energy Isolation: The equipment should now be inspected to ensure all moving parts have ceased. This includes checking for areas which may have potential stored energy, such as those within pneumatic and hydraulic systems or spring-driven parts. These should be carefully blocked with the appropriate equipment to ensure unexpected movements do not occur during the maintenance or repair work.

Verify Isolation: At this stage it is important to verify each aspect of the isolation. This includes ensuring all workers are kept clear of the area, lock-out devices are secure and correctly applied with associating tags, and that any moving parts have been blocked. Once this is completed, the try-out phase can begin.

Try-out: The try-out phase of the procedure involves attempting to restart the equipment. Should the equipment have more than one energy source, it is important to thoroughly check each one has been safely isolated; this is especially true of equipment which may operate with timers and sensors, as these may restart unexpectedly. Once it has been confirmed all aspects of the equipment have been safely isolated and cannot be restarted, the controls should be switched off again. Should the equipment restart during the try-out phase, the LOTOTO procedure needs to restart and a full investigation into what did not work needs to take place.

Work: As all areas of the equipment have been safely locked out and checked thoroughly, the necessary work can begin.

- Re-energization: After the necessary work has been completed the lock-out devices can be removed and the equipment restarted in line with manufacturers’ instructions. It is important to remember that these devices should only be removed by the person who applied them.

In order to complete a LOTOTO procedure, all workers should be thoroughly trained on the method and the usage of the appropriate devices. This is imperative for ensuring a safe lock-out.

Procedure to handover in case of shift/ person changed:

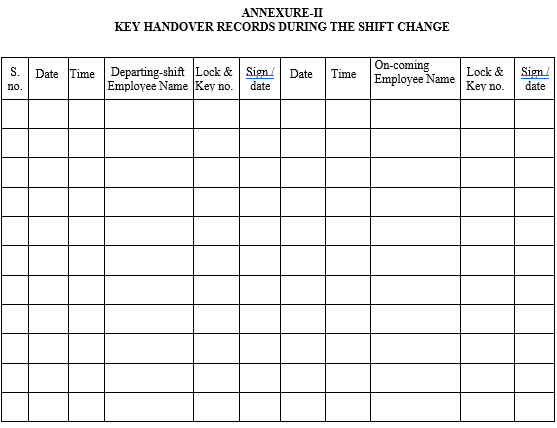

The site supervisor coordinates the lockout procedure by replacing the departing-shift employee’s lockout device with his or her own – subsequently removing these locks only after the oncoming authorized employee has applied his or hers lock. Application and removal of lock shall be entering in annexure II. This method often is used when there is a time lag between the two shifts.

Hand-over method: When lock is applied then it shall be entering in Annexure II and during shift end lock will be removed and next shift person place his lock and record in Annexure II. No. of content of LOTOTO Previous shift person will remove the lock in the presence of next shift employee. When service or maintenance work has been completed, if find that a lock belonging to an authorized employee presumed to have left the building and their lock is remains secured to an energy isolation point. To resume production, this lock must be removed to cut the lock in presence of plant manager from the energy isolation devices. To properly do so, the employer before cut the lock must follow these three steps in order:

- Verify that the employee is not on-site.

- Make all reasonable efforts to contact the employee.

- Confirm or inform the employee that the lock was removed on his or her return to work.

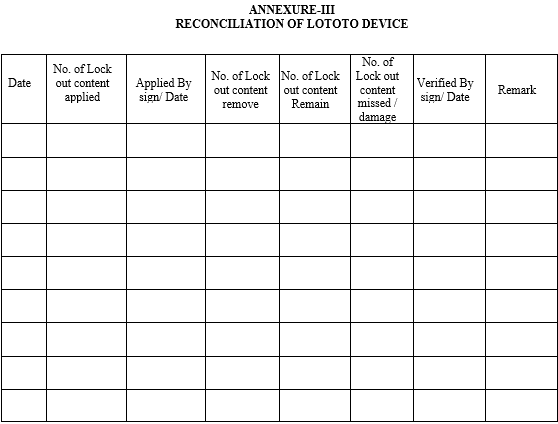

At the time of application and removal of Lock out content from energy point to be recorded in annexure III. If any content is missing investigation to be carried out.

Ensure that no duplicate key is allowed for lock out device. If person lost the key then lock should be cut in the presence of supervisor.

If due to any reason if person leave the premises before completion of shift then supervisor will appoint the another person to applied his lock out device, if another person also not available then supervisor will applied his lock out devise.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/lock-out-tag-out-try-out-lototo/

REFERENCES:

NA

ANNEXURES:

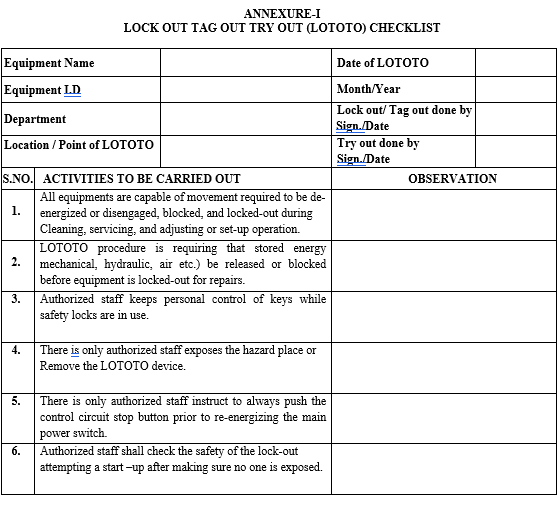

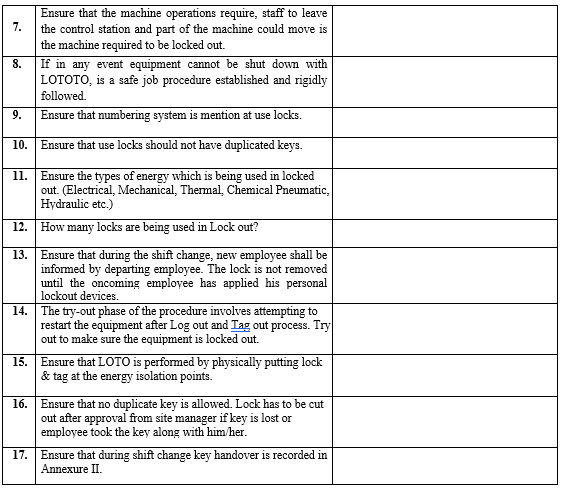

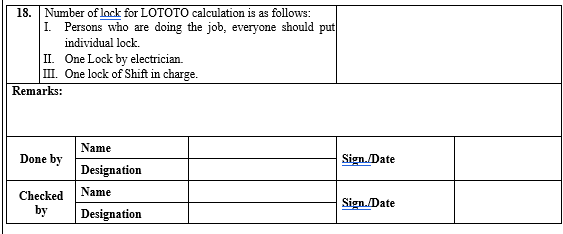

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Lock out Tag out Try out checklist |

| Annexure-II | Key handover records during the shift change |

| Annexure-III | Reconciliation of LOTOTO device |

ENCLOSURES: SOP Training Record

DISTRIBUTION:

| Controlled Copy No. 01 | : | Quality Assurance Head |

| Controlled Copy No. 02 | : | Engineering Head |

| Master Copy | : | Quality Assurance Department |

ABBREVIATIONS:

| SOP | : | Standard Operating Procedure |

| No. | : | Number |

| QA | : | Quality Assurance |

| EG | : | Engineering |

| LOTOTO | : | Lock out Tag out Try out |

| Etc. | : | Etcetera |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

ANNEXURE-I

LOCK OUT TAG OUT TRY OUT (LOTOTO) CHECKLIST

ANNEXURE-II

KEY HANDOVER RECORDS DURING THE SHIFT CHANGE

ANNEXURE-III

RECONCILIATION OF LOTOTO DEVICE

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/lock-out-tag-out-try-out-lototo/