- OBJECTIVE:

To lay down a procedure for Movement of Batch Documents.

- SCOPE:

This SOP is applicable for Movement of Batch Documents at {Company Name} {Company Location}.

- RESPONSIBILITY:

QA, QC, Production & Warehouse- Follow the instruction as per procedure.

QA Head –Training, approval & implementation of SOP.

- ACCOUNTABILITY:

QA Head

- PROCEDURE:

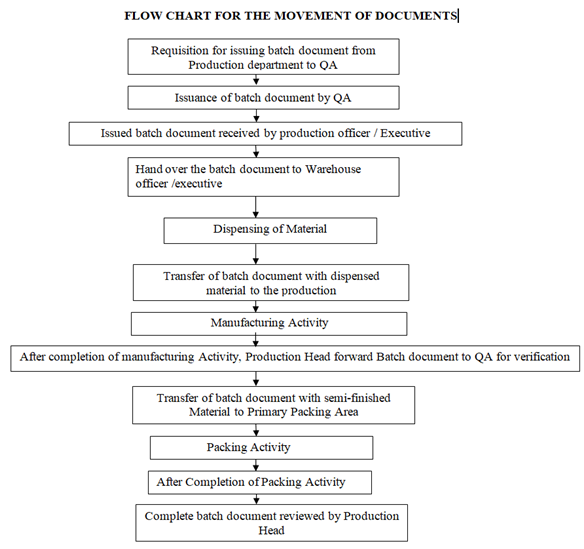

- On receipt of requisition for issuing of documents from production department, QA shall issue the batch document (BMR & BPR) to production.

- Production officer/executive shall review the issued batch document and handover to Raw material warehouse officer/ Executive for dispensing of raw materials & Packing material warehouse officer/ Executive for dispensing of packing materials.

- On the basis of material Requisition, Warehouse officer/executive shall check all the materials physically and start the dispensing activity.

- After the completion of dispensing, Warehouse Officer/Executive return Batch document along with dispensed material to the production Officer/Executive.

- After Receiving the Batch Documents, Production Officer /Executive starts the manufacturing Activity.

- After the completion of manufacturing process, production officer/executive forwards the batch document to production head.

- Production Head shall check the reconciliation record in BMR and forward to QA Officer/Executive for verification.

- After reviewing the Batch manufacturing Record, Batch document with semi-finished material Transferred to Primary packing Area.

- After the completion of packing process, production officer/executive forwards the batch document to production head.

- Production Head shall check the reconciliation record in BPR and forward to QA Officer/Executive for verification.

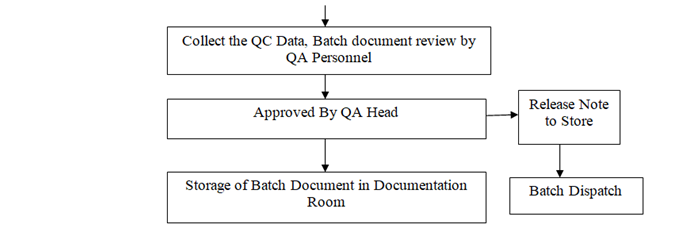

- QA officer/executive shall collect the respective QC data and review the batch documents.

- QA officer/executive forwards the batch document to QA head for final approval & release of batch.

- QA Head verify the batch document and put the signature on BPR & issues a release note to Warehouse Head.

- After releasing the batch, batch document shall be stored in the documentation room. Batch document (BMR & BPR) shall be moved along with material from dispensing to final process.

- Movement of batch documents shall be as per following flow chart.

- REFERENCES:

Not applicable

- ANNEXURES:

Not applicable

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

| Controlled Copy No. 01 | : | Head Quality Assurance |

| Controlled Copy No. 02 | : | Head Production |

| Controlled Copy No. 03 | : | Head Warehouse |

| Master Copy | : | Quality Assurance Department |

- ABBREVIATIONS:

| QA | : | Quality assurance |

| SOP | : | Standard operating procedure |

| BMR | : | Batch Manufacturing Record |

| BPR | : | Batch Packing Record |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be recorded manual |