- OBJECTIVE:

To describe a standard operating procedure for Noise Monitoring.

- SCOPE:

This Procedure is applicable for Noise Monitoring at {Company Name} {Company Location}.

- RESPONSIBILITY:

- In charge EHS.

- ACCOUNTABILITY:

QA Manager shall be accountable for Approval & Implementation of SOP.

- PROCEDURE:

- The Noise generating from different sources and levels to be monitored in different areas like.

- Office

- Production

- DG Sets

- Security

- HVAC

- Utilities

- The Noise levels monitoring by using noise measuring meter in different areas on activity base.

- The noise level measuring team shall monitor the noise periodically at least once in 3 months at the variation of +15 Days and record in Annexure-I (Noise Level Monitoring).

- Impact of different noise level:

- 70 dB or lower: Safe for prolonged exposure over 24 hours.

- 85 dB: Safe for up to 8 hours of exposure per day. Above this, the safe exposure time halves with every 3 dB increase.

- 140 dB: Threshold for immediate pain and potential permanent hearing damage.

- REFERENCES:

Not Applicable

- ANNEXURES:

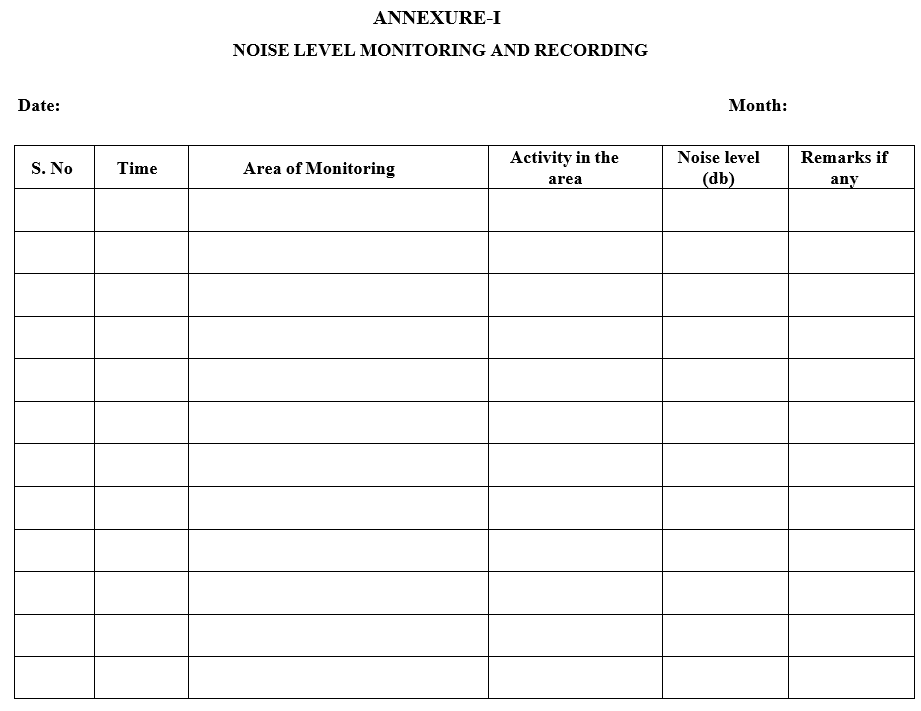

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Noise Level Monitoring and Recording |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

| Controlled Copy No. 01 | : | Safety Health & Environment |

| Master Copy | : | Quality Assurance Department |

- ABBREVIATIONS:

EHS : Environment Health & Safety

HVAC : Heat ventilation air conditioning system

SOP : Standard operating procedure

DG : Diesel generator

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

NOISE LEVEL MONITORING AND RECORDING