- OBJECTIVE:

To lay down procedure for the operation of DG set.

- SCOPE:

This SOP is applicable for the operation of DG set at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering is responsible for perform the activity as per the SOP.

- HOD/Executive – Engineering is ensure the compliance as per SOP.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- Precautions:

- Check the engine oil level with dip stick oil gauge, if required top up engine oil up to the high level mark.

- Check the coolant level, if required top up the coolant up to the maximum level.

- Check and Ensure battery charging system and batteries.

- Battery voltage should not be less than 24V.

- Check cooling tower water level, if required top up the water up to the maximum level.

- STARTING PROCEDURE

- Release the emergency push button on DG power command control.

- Turn Off / Manual / Auto selector switch to Manual position.

- Press manual Run / Stop button to start the DG set.

- Check and ensure the oil pressure, voltage, and RPM in DG power command control panel.

- Release the emergency push button in the DG control panel.

- Close the ACB manually in the DG control panel.

- Close the DG incomer ACB in the power control centre.

- Switch ON the CT pump, ID fan in the utility MCC panel.

- Enter the readings in the DG set running parameters log sheet for every hour.

- STOPPING PROCEDURE

- Check and ensure the EB power supply presence & ensure the 3 Phase voltages should be in-between 415 – 420 Volts.

- Note down the final readings in the DG set running parameters log sheet.

- Open the DG incomer ACB in the power control centre and close the EB Incomer ACB in the power control centre.

- Switch ON the CT pump, ID fan in the utility MCC panel.

- Open the ACB of DG control panel manually and press the emergency push button.

- Run the DG set for 5 minutes in idle condition.

- Press manual Run / Stop button in the power command control to stop the DG set.

- Turn Off / Manual / Auto selector switch to “O” position.Press the emergency push button on DG power command control.

- Switch OFF the CT pump and ID fan in the Utility MCC panel.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | DG set running parameters log Sheet |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

DG Set : Diesel Generator Set

KVA : Kilo Volt Ampere

PCC : Power Command Control

RPM : Revolutions Per Minute

ACB : Air Circuit Breaker

CT : Cooling Tower

ID : Inner Draft

MCC : Motor Control Centre

EB : Electricity Board

SOP : Standard Operating Procedure

NA : Not Applicable

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

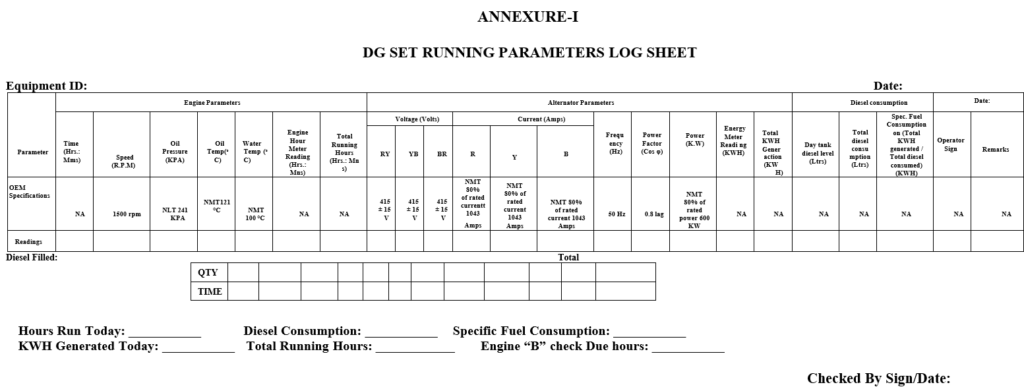

ANNEXURE-I

DG SET RUNNING PARAMETERS LOG SHEET