- OBJECTIVE:

To lay down procedure for the operation of Water Cooled Chiller.

- SCOPE:

This SOP is applicable for the operation of Water Cooled Chiller at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering is responsible for operating the equipment as per the SOP.

- HOD/Executive – Engineering is ensure the compliance as per SOP.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- Precautions:

- Check the level of soft water in the overhead tank, it should be 3/4th or above, if needed fill with soft water.

- Check the cooling tower water level which should be above half level.

- Ensure that the suction and delivery valves of chilled water circulation pumps and cooling water pump are open.

- Ensure cooling towers and chilled water tank make-up water line valves are in open position.

- Ensure condenser and evaporator in & outlet lines valves are in open position

- Ensure power supply to panel.Check and ensure the oil level as per the mark given on the view glass.

- PRE START UP

- Switch on the input power supply of the chiller.

- Start the cooling water pumps and related cooling tower fans.

- Start the chilled water circulation pumps one by one based on plant load.

- Check and ensure no air lock occurred in the chilled water distribution loop

- STARTING PROCEDURE

- Before starting the unit, ensure that all AHU’s are in OFF condition, but valves should be in OPEN condition.

- Any set points which are desired to be changed may be programmed.

- All Control Center set points should be programmed before the chiller is started.

- Maintain the required inlet chilled water pressure. If the flow rate is less than minimum rated flow (3 kg/cm2), the flow switch will be tripped off the system.

- After getting the flow press and then touch local ON button in MMI and then start the chiller.

- When the chilled water temperature reaches 6.5ºC, and then starts the AHU’s.

- Set chilled water outlet temperaure NLT 5℃

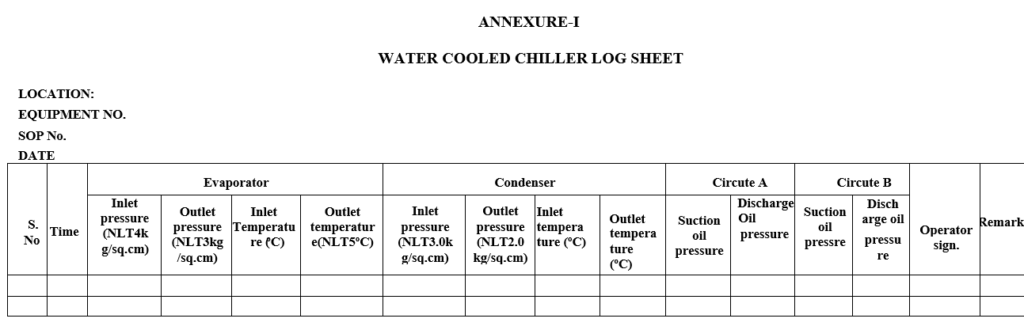

- Every two hours note down the readings as per enclosed Annexure-I.

- STOPPING PROCEDURE:

- Press the and then touch STOP button and then stop the chiller.After 1 to 2 minutes the system will be shut down completely.Switch off the chiller pumps and cooling tower pumps.

- Switch off the cooling tower fans.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Water Cooled Chiller Log Sheet |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

AHU : Air Handling Units.

MMI : Man, Machine Interface

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

WATER COOLED CHILLER LOG SHEET