OBJECTIVE:

To lay down a procedure for operation of Air Handling Unit.

SCOPE:

This SOP is applicable for Operation of Air Handling Unit at {Company Name} {Location}.

RESPONSIBILITY:

Technician- Follow the Instruction as per procedure.

Engineering Officer/Executive- Execution as per laid down procedure.

Engineering Head- Technical correction, review, training & monitoring of SOP.

ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

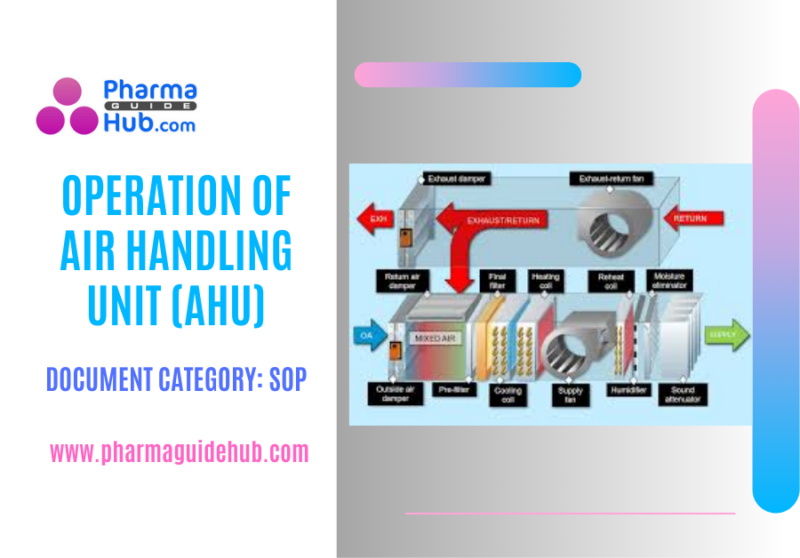

ABOUT HVAC SYSTEM:

HVAC systems are critical in pharmaceutical manufacturing, ensuring product quality and safety. They meticulously control temperature, humidity, and air cleanliness, essential for sensitive drug production. These systems employ HEPA filters to remove airborne particles, preventing contamination. Precise pressure differentials between rooms prevent cross-contamination. Temperature and humidity stability safeguard drug efficacy. Compliance with Good Manufacturing Practices (GMP) is paramount, requiring validated HVAC systems.

PROCEDURE:

Precautions and general conditions:

Use necessary safety wear like safety shoe, nose mask and helmet if required.

Ensure that chilled and hot water inlet and outlet valves are in open condition.

Ensure that chilled water circulating pressure in inlet line is maintained around 0.8 to 2.0 kg/cm² and in outlet line 0.6 to 1.6 kg/cm² & hot water circulating pressure in inlet line is maintained around 0.8 to 2.0 kg/cm ² and in outlet line 0.6 to 1.6 kg/cm².

Ensure that chilled water inlet temperature is NMT 8ºC; Outlet temperature is NMT 15ºC and Inlet Hot water temperature 40ºC to 50 ºC; Outlet hot water temperature 30ºC to 40 ºC to achieve the required conditions in the areas.

Do not disturb the supply, return, fresh air dampers unless until the pressure differential in the area got disturbed.

Starting Procedure of Air Handling Unit:

All AHU shall be run as per shift planner whether area is working or not.

AHU shall be started before half an hour, starting the plant.

Shift planner shall be received from HR department via email.

Check the inlet and outlet pressure of the chilled water & hot water.

Open the chilled water and Hot water pipe line valve of respective AHU.

If any discrepancy found in the chilled water & hot water line inform to the utility technician for the same.

Check the availability of power to the control panel.

Switch on the MCB of the respective AHU.

If the AHU is running for 24 hours enter the initial start time in the operating log sheet and write continue till the AHU is stopped.

Ensure that all areas AHUs should be run continuously as per shift planner.

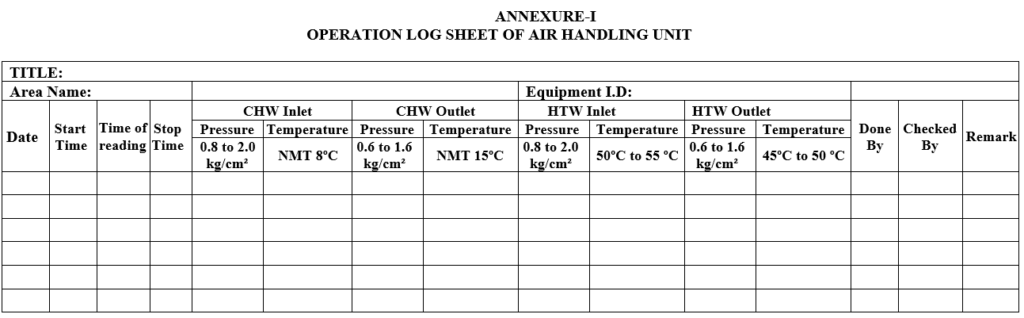

Update the operation record of AHU every 4 hour as per Annexure-I.

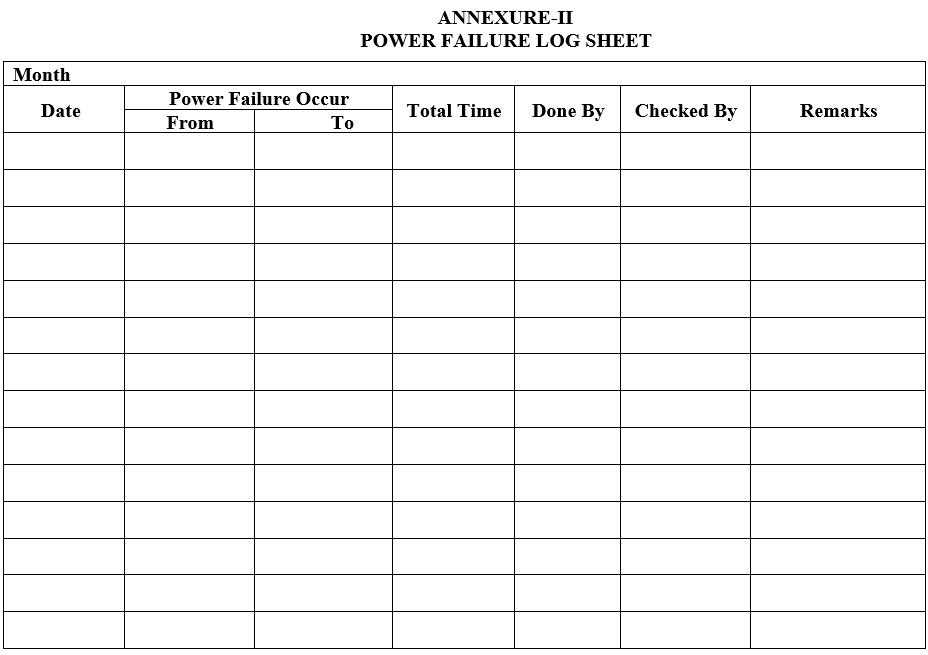

Whenever power failure occur, after resuming the power the equipment starts automatically, update the

Power failure time in the power failure log sheet as per Annexure-II.

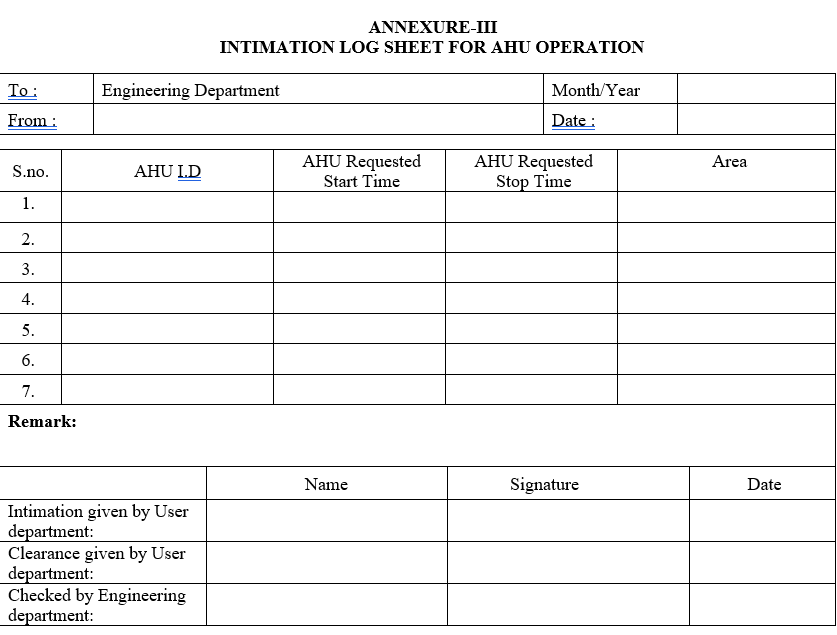

Intimation for AHU operation shall be given, whenever any department wants to start the AHU of there area either before the shift starting or after the shift completion or whenever required before or after shift planner.

Stopping Procedure of Air Handling Unit:

AHU shall be stopped 15 minutes delay after completion of the plant shift.

Switch off the Main Passage AHU first, sub-passage next and critical area air handling unit in the last, as opposite to the starting procedure.

Switch off the MCB of the AHU so that the equipment shall be switched off completely.

Close the chilled water inlet and outlet valves.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-air-handling-unit-ahu/

REFERENCES:

Not Applicable

ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Operation Log Sheet of Air Handling Unit |

| Annexure-II | Power Failure Log Sheet |

| Annexure-III | Intimation Log sheet for AHU operation |

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

Master Copy Quality Assurance Department

Controlled Copy No. 01 Head Quality Assurance

Controlled Copy No. 02 Head-Engineering

ABBREVIATIONS:

SOP : Standard Operating Procedure.

QA : Quality Assurance.

AHU : Air Handling Unit

NA : Not Applicable

MCB : Miniature Circuit Breaker

HEPA : High Efficiency Particulate Air

NMT : Not More Than

HTW : Hot Water

HR : Human resource

EG : Engineering

PGH : Pharmaguidehub

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

ANNEXURE-I

OPERATION LOG SHEET OF AIR HANDLING UNIT

ANNEXURE-II

POWER FAILURE LOG SHEET

ANNEXURE-III

INTIMATION LOG SHEET FOR AHU OPERATION

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-air-handling-unit-ahu/