- PROCEDURE FOR THE OPERATION OF AUTOMATIC TABLET COATING MACHINE :

- Make :SEJONG-SFC-100FH & SFC-130 FH

- Tablet coating is a process where a thin layer of material is applied to the surface of a compressed tablet. A machine is used for the coating of tablet that is called tablet coating machine.

PRE SET UP:

- Check for the cleanliness of the machine and area.

- Remove the CLEANED label and affix UNDER PROCESS label.

- Switch on the main power supply by turn the power control key to ON. Release the emergency button.

- The following controls are available in the main control switch pane:

- Exhaust air pressure Manometer: Indicates the exhaust air pressure of heated air exhaustion top duct.

- Main Air Gauge: Indicates the total compressed air pressure that is supplying to the machine.

- Pump Air: The gauge shows the pressure of Diaphragm pump for sugar coating. Pull the regulator and rotate it clockwise to increase the pressure of air.

- CYL AIR: The gauge indicates the cylinder pressure that is supplying to the spray gun.

- ATOM AIR –Gun 1: Indicating the atomizing air pressure that is supplying to the spray gun1.

- ATOM AIR-GUN2: Indicating the atomizing air pressure that is supplied to the spray gun2.

- Air Flow Meter –Gun1& 2: Delicate adjusting the atomizing air pressure that is supplying the spray gun 1and 2 and indicates with ball which is installed on the meter. To adjust its pressure, rotate the regulator clockwise to increase the pressure and rotate it anti clockwise to decrease.

- Lamp ON/OFF switch: for coating pan light operation.Prepare the coating solution as per respective BMR in the solution tank, adjust the speed of agitato by regulate the air pressure.

- Check the air pressure should be ‘NLT’ 5 kg/cm2.

- TOUCH SCREEN: The touch screen panel having following keys/switches:

- Key switch: This key is a control power key for touch screen. If the key switch is on ,the screen is displayed.

- Pan ON/OFF select Switch: Coating pan turn and stop is controlled by pan ON/OFF select switch.

- Discharge ON/OFF switch: In order to discharge the coated tablets after completing production, this switch should be on position. If both above two switches are in off mode than this switch is not activated.

- Spray ON push button switch: Auto spray function will start through spray ON push button is coating cycle screen is set.

- Main coater, exhaust Fan and supply Fan should be turned on all together before starting spray ON.

- Spray OFF push Button switch: If this button is pushed, the spray will stop.

- Buzzer RESET switch: During operation, if any alarm comes then the buzzer will works. Eve though Buzzer is off, the lamp keeps blinking).

- Emergency Switch: Machine can be stopped by this switch, in case of any problem has taken place on operation.

- SET-UP – FIXING OF GUNS:

- Open the sight glass window.

- Take out the spray gun setting bar by pressing “OUT of ‘Gun Sliding System” in operation screen.

- Attach the gun to the gun-fixing pipe.

- Lock the guns by tightening the nut.

- Connect pneumatic connector to the gun for atomization, pan air & needle opening.

- Connect solution pipeline at the position specified.

- Adjust the spraying angle and distance for coating using setting angle.

- Load the tablets into the pan.

- Fix the gun header assembly in to original position.

- PERISTALTIC PUMP SET UP:

- Open the roller assembly cover on the peristaltic pump.

- Pass the solution tube from the solution holding tank through the rollers on the.

- Peristaltic pump and connect it to the inlet connector present on the mouth of the pan.

- Connect one tube from the outlet connector on pan mouth to the solution holding tank.

- Connect tubes from the inlet opening on the mouth of the pan to the inlet manifold on the sliding bar.

- Connect tube from the outlet opening on the mouth of the pan to the solution return manifold on the gun header.

- Fix the gun header assembly in to original position.

- Close the door of the coating machine.

- Adjust the speed of pump with speed control knob. The direction also can be changed by pressing the direction switch.

- Coating solution shall be prepared as per BMR and poured in to the coating solution tank, close the lid of the tank.

- Label the coating solution tank with UNDER PROCESS label.

- OPERATION: SETUP: The following initial screen shall be displayed on the power supply.

- Touch Login icon in the above screen, enter user id and password by using keypad. The following parameters are available in this main screen.

- 1) Product manager: production parameters and configuration can be checked in this window.

- 2) Operation: This is the setting window for the production parameter and system configuration.

- 3) Coating cycle: Auto coating cycle parameter is set in this window.

- 4) Safety Message: When the alarm is working, the alarm point is displayed in this mode.

- 5) Monitor: The operation status of coating pan, Supply air, Exhaust Fan, Tank and supply gun is displayed this window.

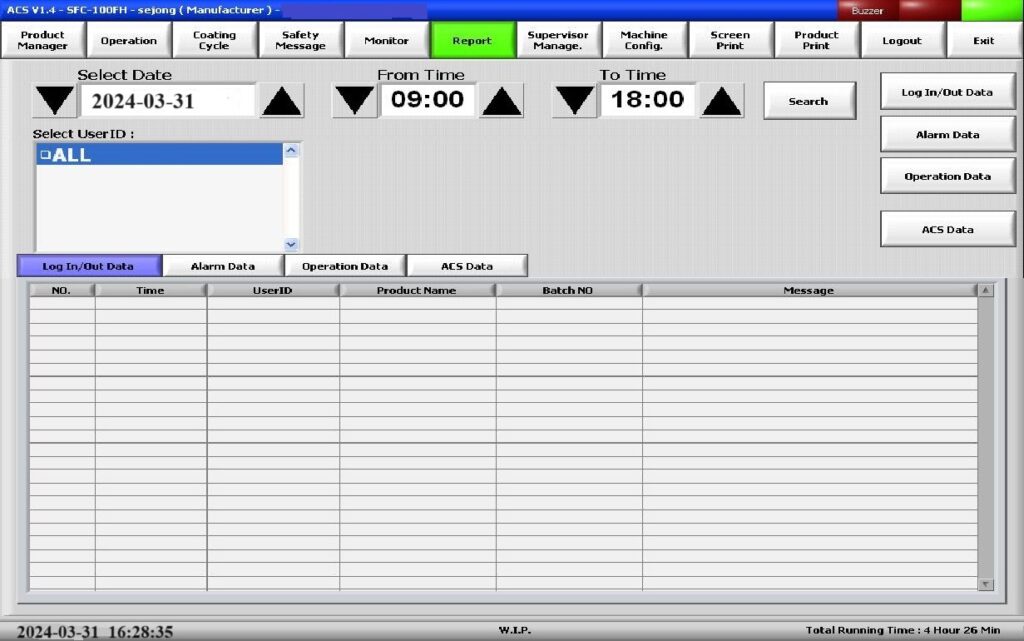

- 6) Report: Data for Log in/logout, alarm history, operation history and ACS history are displayed in this window and can be printed out.

- 7) Supervisor manager: operation user &Level are displayed and set in this mode.

- 8) Machine config: Various machine configurations are set in this mode.

- 9) Screen print: current activated screen is printed out in this icon.

- 10) Product print: Production report is printed out through this icon.

- 11) Log In/Out: This icon is for Log In and Out.

- 12) Exit: Program is closed with this button. 13) Total Run time: Total machine running time is indicated.

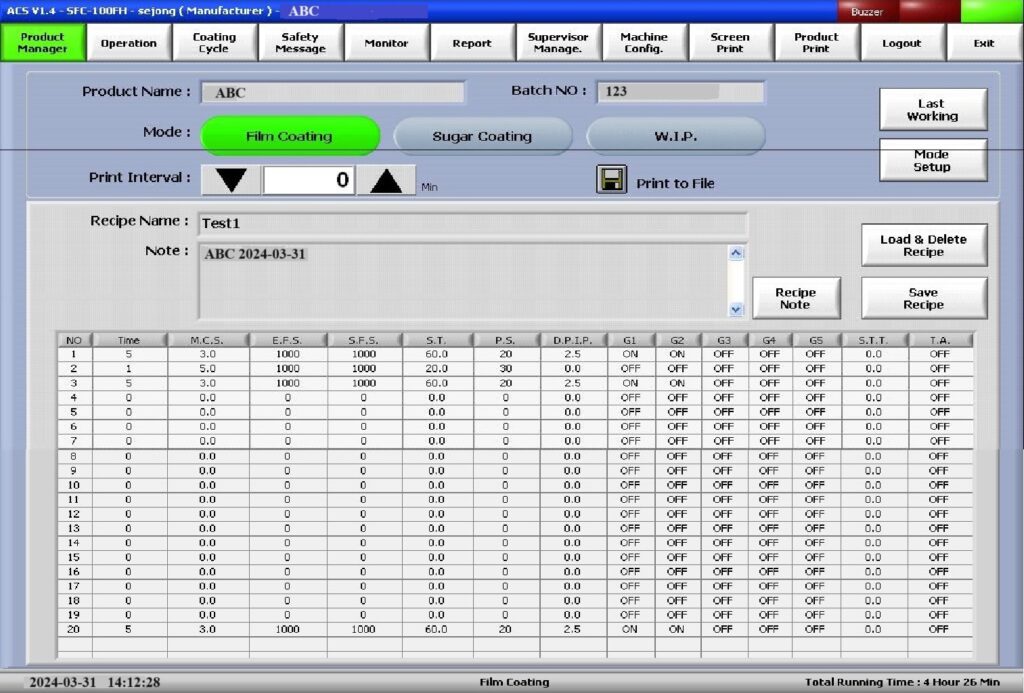

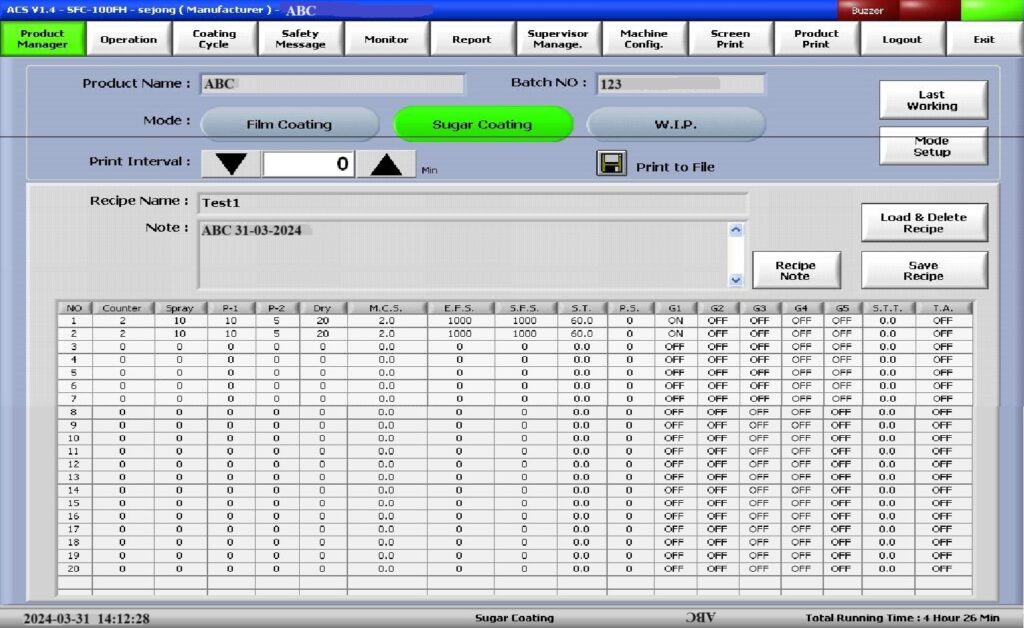

- Product Manager: production parameter and system configuration is displayed in this window.

- Last Working: Lastly recorded product name and Batch No are displayed in this window. On touching “Last Working” icon the following window will be displayed.

- Touch continue icon to continue the last working condition.

- Touch ‘Cancel’ icon to close the window.

- Mode Set up: Product Name and Batch No. can be input and saved; coating mode (Film/WIP) can be also saved.

- On touching Mode setup icon Coating mode reset window will be displayed

- Apply: present setting value is saved and displayed in Product Manager Window.

- Cancel: press this icon to cancel.

- Film Coating: Touch this button to activate the film coating.

- WIP: touch icon shall be used during cleaning.

- Print Interval: Set the print interval time in this screen. Print interval should be set more than 10Min.

- Load & Delete Recipe: Touch this icon then the following load recipe window will be displayed. Select the required recipe and touch LOAD icon to load the recipe. Based on the loaded data the coating process will proceed. Touch DELETE icon to delete the recipe.

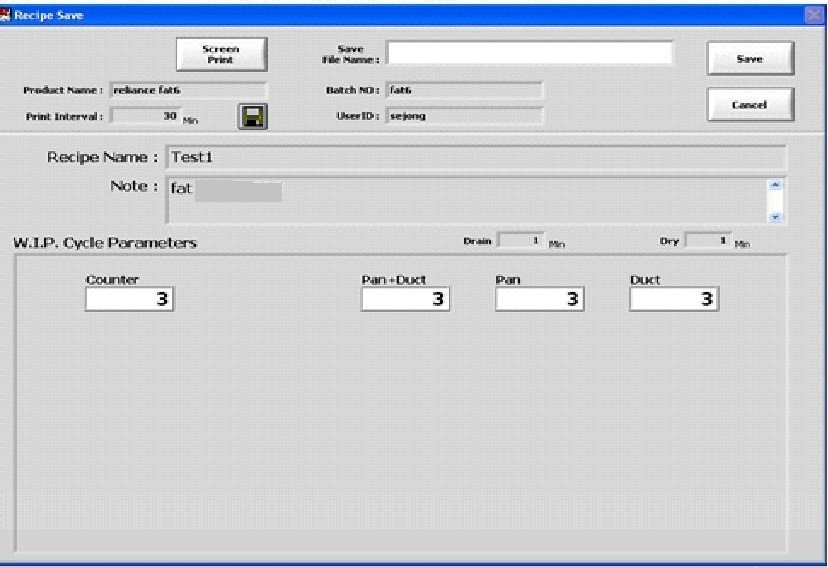

- Save Recipe: Touch this icon then the following window shall be displayed. Product Name, Recipe Note, Batch No, print interval and setting condition in coating cycle screen can be saved. Touch save icon then the input data is saved as a file name in data base. Touch Cancel icon to exit from this window

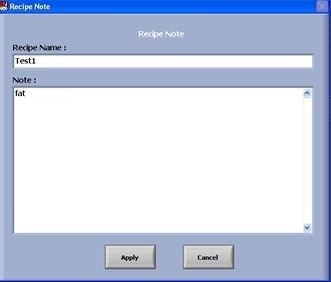

- Recipe Note: production parameter and note is saved in this window. Touch Recipe note then the following window shall be displayed. After inputting recipe name and note text, data is saved by touching apply icon. Touch cancel icon to exit from this window.

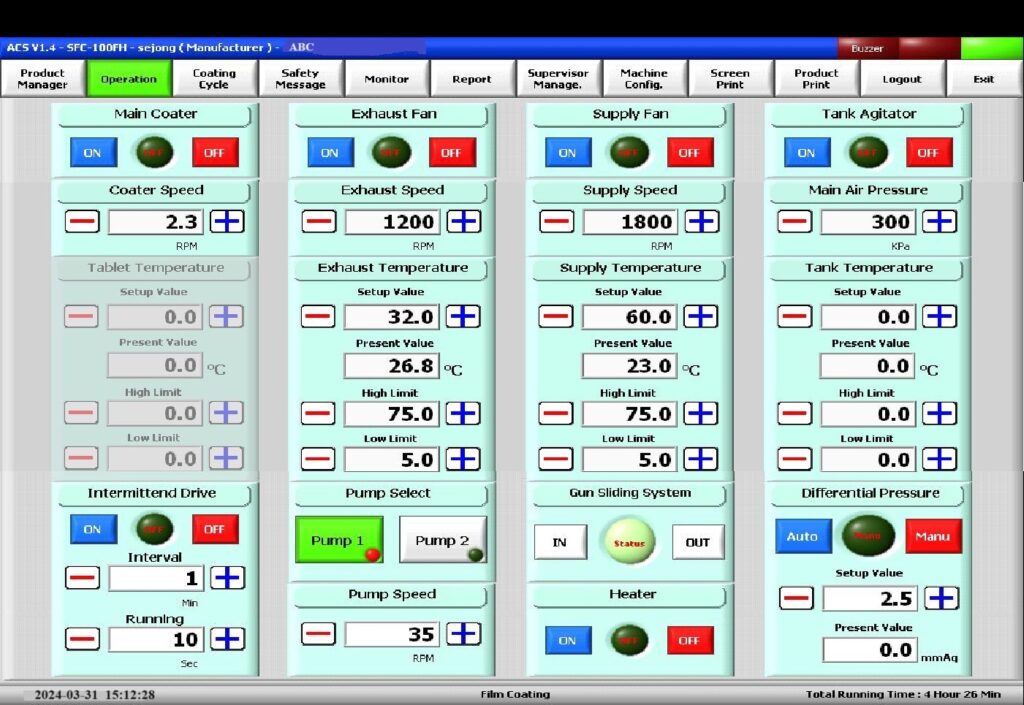

Operation: Touch Operation icon in the main screen the following window shall be displayed. The following parameters can be settled in this screen.

- Main Coater: Coating pan ON/OFF switch .coating pan starts driving with this button and pan switch in the panel.

Note: Even though the main coater is turned on with ON in the screen, pan cannot be started if pan switch is in off position.

- Coating speed: This icon shall be control the speed of coating pan. The pan speed can be increased by pressing (+) icon and can be decreased by pressing (-) icon.

- Tablet Temperature: The bed temperature of tablets is controlled in this screen. The temperature can be increased by (+) icon and decreased by (-) icon.

- Exhaust Fan: Touch ON icon to switch on the duct collector, touch OFF icon to switch off the dust collector.

- Exhaust Speed: Exhaust pan speed can be increased by (+) icon and decreased by (-) icon.

- Exhaust Temperature: Exhaust temperature can be set in this screen. Exhaust temperature can be increased by (+) icon and decreased by (-) icon.

- Supply Fan: inlet fan speed can be set in this screen. Touch ON icon to switch on the heater, press OFF icon to switch off the heater.

- Supply Fan Speed: supply fan speed can be increase (+) or decreased by pressing respective button.

- Supply Temperature: Inlet air temperature can be settled in this screen. Supply temperature can be increased (+) or decreased by pressing respective button.

- Tank Agitator: Solution tank ON/OFF can be controlled by this screen. Touch ON icon to start the air motor, touch OFF icon to off the air motor.

- Main Air pressure: Low limit of main air for the machine is set in this screen.

- Intermittent Drive: this function can be used In case of warm-up process before the production or required to be kept the current status during the production. Set the interval time and running time. Note: When intermitted drive is working, main coater on the screen should be off and coating pan select switch should be on

- Pump Select: Selected pump between sugar pump and film pump can be checked in this window. If pump 1 is touched, pump 1 is selected and pump 1 button colour is changed into green. If pump 2 is touched, diaphragm pump is activated with green indication.

- Pump Speed: Pump speed can be increased by pressing (+) button and decreased by (-) button.

- Gun Sliding System: Gun arm can be slide out and in with this function by cylinder. If OUT is touched sliding bar is moved out. If IN is pressed, sliding bar is moved in.

- Differential Pressure: The DP of coating pan can be controlled by this window. If Auto is selected, then exhaust fan speed is automatically changed in order to keep the desired air pressure in coating pan. Set required DP in set value column. If Manu is selected then the exhaust fan speed can be controlled by manual.

- COATING CYCLE: Touch coating cycle in the main screen then the coating cycle window shall be displayed. Screen for Selected Mode in Mode Setup of product manager is displayed.

- Setup Value: Production data is set in this screen.

1) Cycle Status: if related cycle status is selected, new value can be inputted or changed. Cycle status is selected between No.1 and No.20. If (-) is touched, cycle status No is changed into lower number. If (+) is selected, cycle status No is changed into higher number.

2) Warming: This function can be used for initial pre warming of tablets.

3) Finishing: This can be used for post warming of coated tablets.

4) Source cycle /Target Cycle: same data of cycle can be copied to prefer cycle. Data from source cycle is copied to target cycle through “Copy Cycle” icon.

5) GUN ON or OFF condition can be set in this screen: Press ON to switch on the spray. Press OFF to turn off the spray.

6) Tank agitator ON or OFF can be controlled by this icon.

7) Following function can be entered in this screen.

a) E.F.S: Exhaust Fan speed.

b) S.F.S: Supply fan speed.

c) S.T: supply temperature.

d) P.S: pump speed.

e) M.C.S: Main Coater Speed.

f) D.P.I.P: Differential pressure inside the pan.

g) S.T.T: Solution Tank Temperature.

h) T.A: Tank agitator.

i) P-1: Pump.

j) P-2: Pump -2.

- Current Value: in case of Auto mode coating, current values are displayed on current value mode. Auto coating process proceeds as following the setting condition of cycle status from No.1 to No.20.The cycle shall pass to next cycle automatically after completion of one cycle.

- Press ‘Reset cycle’ icon to start the coating from first cycle onwards during auto mode.

- Note: In case of Auto coating, Auto Coating Stop S/W should be pushed on the panel in order to reset the cycle.

- Safety Message: During the auto mode, if there is any trouble with the system, trouble source will be described in safety message mode. The following alarms are available in this screen.

- Main Coater Alarm: This alarm shall be generates when the main coater is trips or bed temperature is high.

- Supply Fan alarm: This Alarm shall generate when the inlet blower trips or when inlet temperature is high.

- Exhaust Fan Alarm: This alarm will generate when the inlet temperature is high or when inlet blower trips.

- Main Air Shortage: If the main air pressure is lower than the limit then this alarm will works.

- Completed Coating: This alarm will generate when completion of coating process.

- Pushed Emergency: in case of Emergency, if the emergency switch is pushed, the machine shall be stopped.

- Opened Sight Glass: If sight glass opened, alarm shall generate.

- Dehumidifier Alarm: Alarm detail description window is opened through Dehumidifier Alarm icon.

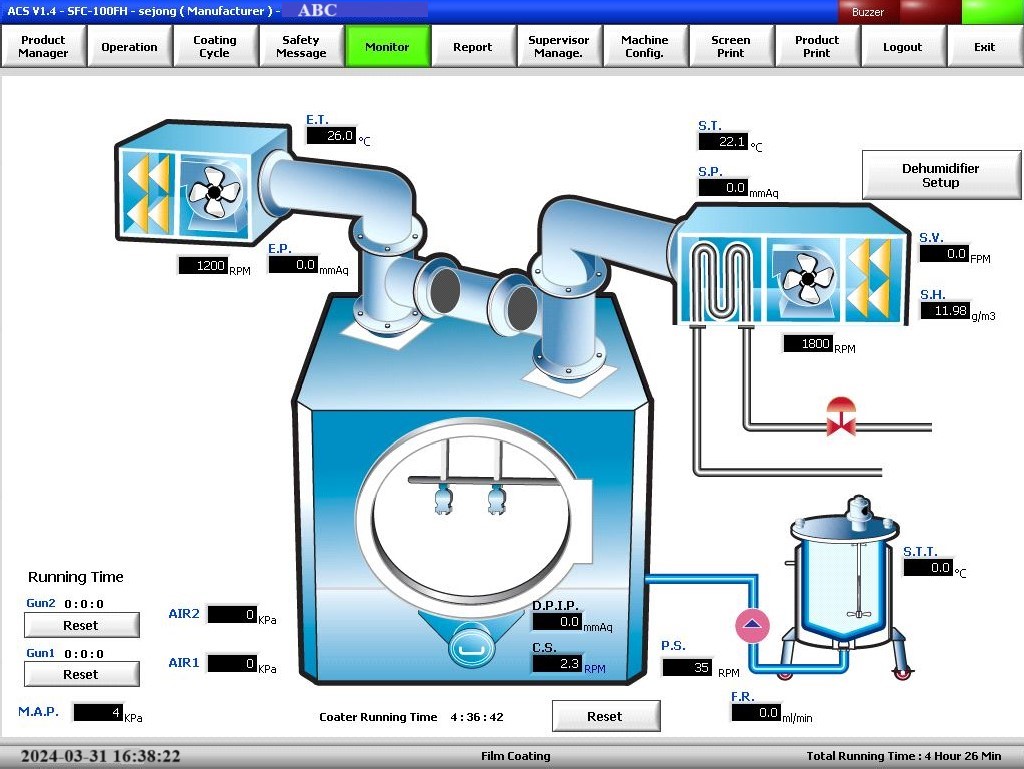

- Monitor: In this screen whole process of coating shall be described with animation, the data.

- Exhaust Fan: The following parameters can be controlled in this icon.

1) Exhaust Temp (ET): Preset value of exhaust temperature shall indicate in this screen.

2) Exhaust pressure: The DP shall be indicated in this column.

3) RPM: Exhaust fan speed shall be indicated in this screen and speed control can be done. Touch ON button to switch on the Exhaust fan; touch OFF button to switch off the exhaust fan.

- Supply Fan: The following parameters can be controlled in this icon.

1) Supply Temp (S.T): Preset value of inlet temperature shall indicate in this screen.

2) Supply Pressure (S.P): The DP shall be indicated in this column.

3) Supply velocity (S.V): Supply air speed is indicated with FPM (Ft/min) unit.

4) Supply Humidity (S.H): Humidity in supply air indicated.

5) RPM: supply Fan speed is indicated and speed control is permitted in this screen.

- Coating pan: The following parameters can be controlled in this icon.

1) D.P.I.P: coating pan inside differential is indicated in this icon.

2) Coating speed (C.S): Coating pan RPM speed is indicated and speed is controlled in operation screen.

- Main Air pressure (M.A.P): The compressed air pressure indicated in this icon.

- Coater Running Time: It shall indicate the machine run time, can be reset by pressing Reset button.

- Report: Log in/Out data, Alarm data, Operation and ACS data are displayed and temperature, Speed, pressure, Humidity, airflow ,spray gun pressure data are described with this graph.

- SETTING OF SPRAY RATE:

- Ensure the ‘ATOMISATION’ pressure is ZERO for Gun1 and Gun2.

- Switch on the peristaltic pump.

- Turn the spray on push button.

- Measure the quantity of solution, if required adjusts the flow. Pour the measured quantity solution in the coating solution tank.

- Turn the pan control air knob clock wise and adjust the following type:

- Uniformly distributed spray band.

- Uniform droplets (devoid of bigger ones).

- No overlapping of spray bands of two consecutive guns.

- Equal diameter (approx.) of spray bands of all the guns.

- Manually sprays the solution on the surface of the Coating pattern checking plate. Note: Clean the Coating pattern checking plate after setting desired spray pattern.

- MACHINE OPERATION IN AUTO MODE:

- Turn the control power key to ON position.

- Enter the required user Id and pass word.

- Go to mode set up and Select the “film coating cycle mode”.

- In the product manager screen.

- Then go to the recipe.

- Load the appropriate recipe.

- Go to operation screen then switch on the individual functions.

- Touch coating cycle and select the film cycle parameters.

- Pre warm the tablets and start the spraying after achieving the bed temperature.

- Continue the coating until getting desired weight build up as per BMR.

- Record the parameters as per frequency mentioned in BMR.After completion of coating cycle dry the tablets as per BMR.

- UNLOADING OF COATEDTABLETS:

- Turn the pan switch to off position.

- Turn the discharge select switch to on position.

- The pan will be turned in reverse direction while discharging the tablets.

- Collect the coated tablets into a pre labelled containers.

- Weigh the tablets and record the weights in the BMR.

- Update the status label as TO BE CLEANED.

- Record the Operating details in the Equipment logbook.

- ABBREVIATIONS:

| No. | : | Number |

| BMR | : | Batch manufacturing record |

| SOP | : | Standard Operating Procedure |