- PROCEDURE FOR THE OPERATION OF COOLING INCUBATOR:

- Make: Newtronic

- NEWTRONIC’s BOD Incubators are ideal used for the growth & storage of bacterial cultures, gentle incubation & conditioning and Media Preparation.

- This procedure is applicable for operation of BOD incubator and data management system, Make: Newtronic.

- Check electric supply (220 VAC), if required connect the equipment through a suitable voltage stabilizer.

- Switch ON the Mains supply of required chamber and set the temperature.

- Operation of temperature Controller:

- As main supply is switched on, the controller display will show following window.

- By pressing up arrow key one can see following windows;

- Default window shows the actual value of the temperature in °C.

- Set temperature and alarm limits in °C.

- Scanner (8 channels) readings in °C.

- PID parameters for temperature accuracy.

- Time in HH:MM:SS format.

- Date in DD/MM/YY format.

- Procedure for Operation of Newtronic Data Management System:

- Open the Newtronic software by double clicking the Newtronic ICDAS 1.2 icon on the desktop.

- Newtronic ICDAS version 1.2 window will be displayed.

- Click on the “Login” on the right side of the Newtronic ICDAS version 1.2 window.

- Enter valid Username and password.

- To change the password:

- In the File menu, select the Change Password.

- Change password window will be displayed.

- Enter the current and new password.

- The password shall not be more than 10 characters.

- Confirm the password.

- Click on “Update” button.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-cooling-incubator-make-newtronic/

- To change the settings:

- In the “Equipment settings” menu, select “Equipment Master”.

- Select the Equipment from the “Browse Equipment” tab.

- Equipment details will be displayed.

- Click on the edit button at the bottom of the window.

- The display name, IP Address, Log rate (Time interval for Temperature recording) and other detail can be changed.

- Click on “Save” button to save the changes made.

- Confirm changes with entering the password.

- Real time display:

- Click real time display menu.

- Select equipment identification number.

- Check set value, low alarm limit and high alarm limit.

- Click legends. Indication color of all probes, set value and low & high alarm indication colors will be displayed.

- Temperature of individual probes can be viewed in real time display.

- Real time summary:

- Click real time summary menu.

- Select the equipment identification number to view the set and actual temperature (ºC) of the BOD incubator.

- If the set parameters of equipment is maintained properly real time display menu will show online.

- Input and Output status:

- Click input/output status menu.

- Select the BOD incubator.Check relevant input, output and analog input status.

- Input status like Mains = ON and Door = Closed,

- Output status like Dry Heater = ON, Analog

- input status of temperature probes (Temperature of individual probes in ºC) can be viewed.

- Alarm log:

- Click alarm log.

- Select equipment name, select date from and to, time from and to and click search.

- Alarms will be displayed.

- Double click the status column of respective alarms, click acknowledge and enter comment then click ok button.

- Report:

- Click report menu, equipment data log window will be displayed.

- Enter the Date and Date To, Time From and Time To for which the report is required.

- Select the equipment name from the drop down list, for which data is required.

- Click on the “Search’ button.Details of Temperature from all channels will be displayed.

- To print the report, Click on the “Report” button.

- Click on “Print” button to take print out.

- Review the equipment log report and retain the hard copy.

- To take print outs “Analysis report” menu on the top of the window can also be selected.

- Click graph to view the graphical chart of temperature with tracked time interval.

- To view the graph, set minimum and maximum value in Y axis scale; set X axis scale value. Click plot chart to view the selected chart.

- To take Backup:

- In the “Admin Utilities” menu on the top of the window, click on “Backup Database”.

- Create a month wise folder in the C:\ drive (Eg: Jan 2025)Select the path from C:\ drive and click on “Create Backup”.Confirmation of Backup will be displayed.

- The frequency of taking backup is: Once in a Month.

- Shutdown of cooling Incubator:

- In case cooling Incubator is to be shutdown, the main switch of the cooling Incubator is to be switched ‘OFF’. When the temperature will fall below low alarm limit, it will generate an alarm. Acknowledge the alarm to silent the hooter.

- Alarm condition:

- In PLC controller one can define specific value of temperature high alarm, temperature low alarm. The controller will give audio and visual alarm if the measured temperature deviates from set value.

- If the mains power supply fails, system should trigger alarm (audible hooter).

- Safety precautions:

- Ensure that the electrical switches are grounded.

- Keep the door of the chamber closed when not in use.

- Call the maintenance engineer in case of any breakdown.

- Alarm acknowledgement:

- Alarms will be logged in case of following reasons,

- Door open

- Temperature high alarm

- Temperature low alarm

- Main fail

- Communication failure

- To acknowledge the alarm click alarm log menu and select equipment name, select date from and to, time from and to and click search.

- Alarms will be displayed. Double click the status column of respective alarms, click acknowledge and enter comment then click ok button.

- Alarm acknowledgement comments; Acknowledge the alarms with the following comments.

| Alarm | Comment | |

| Door open | Door opened to load/unload the plates Door opened for cleaning of incubator Door opened to check the analyzed plates | |

| Temperature high alarm/ Temperature low alarm | If the high/low alarm is logged and the temperature is tracked in the specified monitoring interval, then mention as; For example, if 8.1°C/1.9°C is observed as a high/low temperature then mention as “Minor excursion from the set temperature observed (8.1°C/1.9°C) which does not have any impact on the incubated plates/cultures. | |

| Temperature high alarm/ Temperature low alarm | If the high/low alarm is logged and the time of high temperature alarm is in between the monitoring interval then the temperature will not be tracked by the software. In such occasions check the previous and next interval temperature of that particular channel for any discrepancy. Case 1: For example, if 8.3°C is observed as high temperature and the time is 10.13 then check the temperature of 10.00 and 10.30 if it is within the limit without any discrepancy mention the comment as, “Minor excursion in temperature observed; the previous and next intervals are found ok. There is no impact to the incubated plates/cultures” | |

| Temperature high alarm/ Temperature low alarm | Case 2: For example, if Channel 2 has shown 8.3°C as high temperature and the time is 10.13 then check the temperature of 10.00 and 10.30 if it is not within the set limit of temperature, then check the temperature of other channels (Time 10.00 and 10.30) and if those does not have any discrepancy mention the comment as, “Minor excursion in channel 2 is observed; temperatures of other channels are found ok. There is no impact to the incubated plates/cultures” | |

| Temperature high alarm/ Temperature low alarm | Case 3: If the temperature discrepancy of all channels goes beyond the limit for more than two hours take necessary corrective action as per the sop . | |

| Temperature high alarm/ Temperature low alarm | If there is a discrepancy from the set temperature with high/low temperature and the logged alarm is Door open, then mention the comment as,“Minor excursion in temperature observed due to door open” | |

| Temperature high alarm/ Temperature low alarm | If due to preventive maintenance, then mention the comment as, “Minor excursion in temperature observed due to preventive maintenance program” | |

| Mains fail | Due to power failure | |

| Communication failure | Due to fluctuation in power. Due to improper connection of LAN. | |

NOTE:

1. Every 30 minutes the software ICDAS monitors the temperature and it is recorded & stored.

2. Take daily printouts from the software, review and retain the reports. In case of holiday take the printout on next working day.

3. Frequency of cleaning shall be once in a week.

4. Click the help menu and select help index, Newtronic data management system user guide will be displayed. The entire operation tips can be viewed by the user.

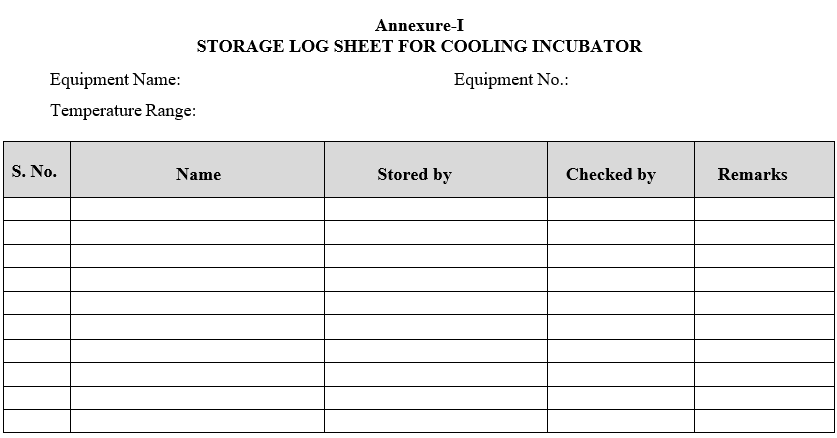

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Storage log sheet for cooling incubator |

- ABBREVIATIONS:

| No. | : | Number |

| IP | : | Internet Protocol |

| BOD | : | Biological Oxygen Demand |

| PLC | : | Programmable Logic Controller |

| ICDAS | : | Information Date Accuracy Transferring System |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

Annexure-I

STORAGE LOG SHEET FOR COOLING INCUBATOR

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-cooling-incubator-make-newtronic/