- PROCEDURE:

- PRECAUTIONS:

- Check the service doors for closed condition before starting the Filter Cleaning equipment.

- Check the damper position as per standard marking, if not in proper position adjust it.

- First switch on the Dust extraction system and then switch on the Filter Cleaning equipment.

- Ensure the drying equipment temperature should not exceed 50ºC.

- STARTING

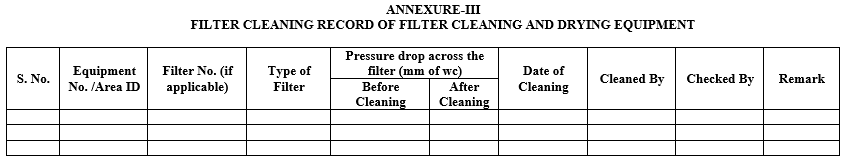

- Ensure that filter cleaning and drying equipment filters are cleaned before starting the operation and record the filter cleaning activity in Annexure-III.

- Dust extraction system filters will be cleaned whenever the differential filters exceed the limit (specified limit: 20 mm of WC to 150mm of WC) or weekly once, whichever is earlier. Filter cleaning activity will be recorded in Annexure-III.

- Start the dust extraction system by pressing the start push button. Start the filter cleaning equipment by pressing the start push button. Observe for any abnormal sound or vibrations.

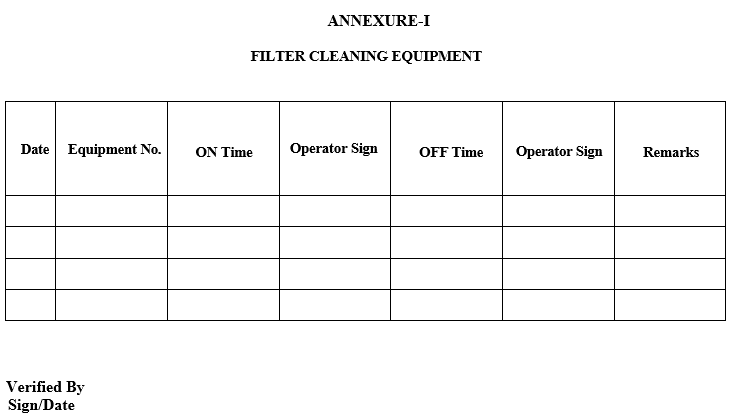

- Record the activity in the Annexure-I.

- Clean the filters as per the SOP.

- Starts the filter drying equipment by turning selector switches to on position and press the start push button and set the temperature to 50ºC.

- Dry the filters as per the SOP.

- STOPPING

- Stop the filter cleaning equipment by pressing the stop push button.

- Record the activity in the Annexure-I.

- Stop the dust extraction system by pressing the stop push button.

- Stop the filter drying equipment by pressing stop push button and turn off the selector switch.

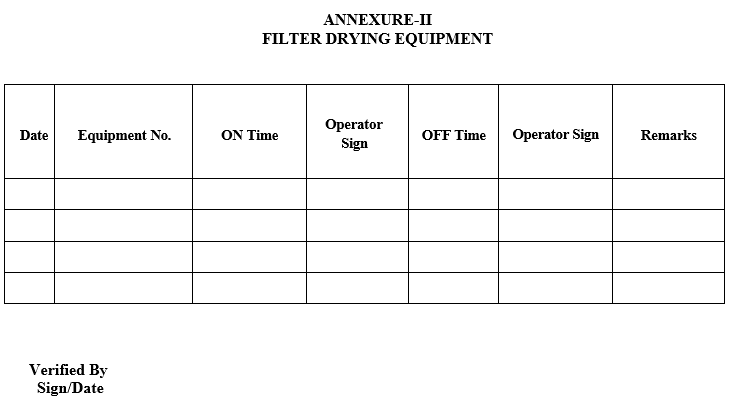

- Record the activity in Annexure-II.

- REFERENCES:

- Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Filter Cleaning Equipment |

| Annexure-II | Filter Drying Equipment |

| Annexure-III | Filter cleaning Record of Filter cleaning and Drying Equipment |

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

- SOP : Standard Operating Procedure

- REVISION HISTORY:

- CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

Annexure-I

FILTER CLEANING EQUIPMENT

Annexure-II

FILTER DRYING EQUIPMENT

Annexure-III

FILTER CLEANING RECORD OF FILTER CLEANING AND DRYING EQUIPMENT