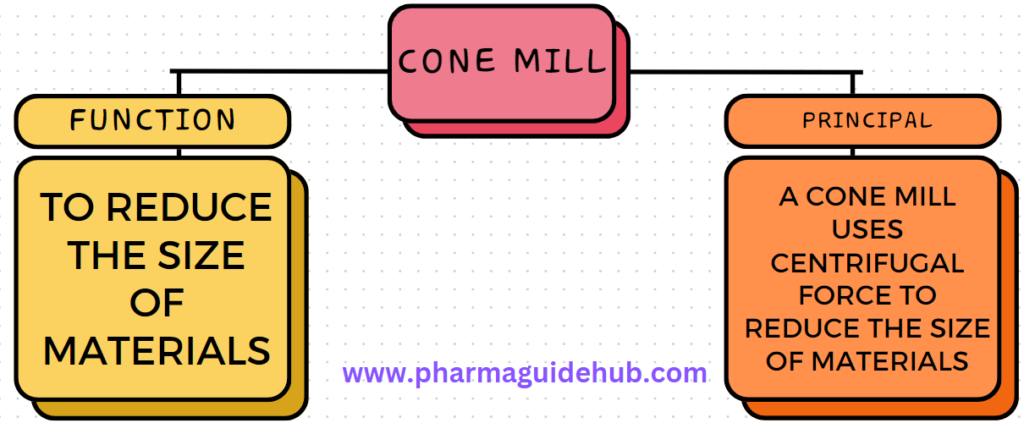

- OPERATING PROCEDURE OF MOBILE CONE MILL :

- A cone mill uses centrifugal force to reduce the size of materials. The mill has a rotating impeller that forces material against a fixed conical screen. The material passes through the screen’s openings, and the particles that are small enough to pass through are discharged from the bottom of the mill. The larger particles are retained and continue to be milled.

- MAKE: TAPASYA

- Check the cleanliness of the area and the machine.

- Remove the “CLEANED” label and affix the “UNDER PROCESS” label to the cone mill.

- Check the room temperature and relative humidity.

- Use cleaned scoops during the milling operation.

- Check the required quantity of all the materials to be milled as per BMR.

SET-UP:

- FIXING OF ROTOR AND BLADES ASSEMBLY:

- Ensure that beaters are fixed in the rotor with help of screw spanner.

- Ensure that blades fixed to the shaft are not touch to the screen, if required use spacers to adjust the gap between screen and beater assembly.

- Align the rotor with blades to the drive shaft. Fix the rotor with blades to the drive shaft with the help of bolt.Tight the bolt with the help of spanner.

- FIXING OF CHARGING PORT, SCREEN AND DISCHARGE PORT:

- Check the screen physically for its integrity.

- Check that gasket is properly positioned on bottom discharge port.

- Align the screen on the bottom discharge port.

- Fix the bottom discharge port along with the screen, clamp with tri-clover clamp.

- Tighten the screws of tri clover clamp.

- Clamp the canister below the discharge port with help of TC clamp for collection of milled granules.

- OPERATION:

- Put the power plug into the power supply socket.

- Switch on the mains and release the emergency button.

- Check that the machine is working properly.

- Start the cone mill by push ON button.

- Load the material into the feed hopper manually with scoop or Clamp the canister.

- Depend on the product requirement, set the speed selector knob in required position as per below mentioned table.

| Sr. No. | Speed selector reading | RPM of motor(Approx) |

| 1 | 1 | 720 |

| 2 | 2 | 1440 |

| 3 | 3 | 2160 |

| 4 | 4 | 2880 |

- Adjust the cone mill speed by keeping the speed selector knob based on product requirements.

- Feed the material at constant rate and regulate the input by adjusting the valve of the canister or by scooping.

- Collect the milled material into collection canister or in to a suitable collection container and label accordingly.

- After completion of the milling operation turn of the knob to stop the machine.

- Close the valve of both canisters.Remove the canister and take it for the next process.

- After ensuring that the machine is stopped, remove the screen, and check its integrity.

- Affix a “TO BE CLEANED” label after the completion of milling operation.

- Record the operation details in the equipment logbook.

- CAUTION:

1) Wait for the machine to stop fully before dismantling the discharge port.

2) Do not overspeed the material, it may jam the mill.