- PROCEDURE FOR THE OPERATION OF OCTAGONAL BLENDER:

- Make: Tapasya (600 Liters)

- An octagonal blender is a type of industrial mixer used for gently blending dry powders and granules. It is known for its efficient and uniform mixing capabilities. The octagonal blender gets its name from the shape of its mixing vessel, which is an octagon (eight-sided shape). This shape, along with the slow speed of the blender, creates a tumbling motion that helps to evenly distribute the materials being mixed.

- Check for the cleanliness of the area and Equipment.

- Remove the “CLEANED” label and paste it into the BMR and affix “UNDER PROCESS” label.

- Transfer all the materials to be lubricated as per the BMR to the blending area.

- Set Up:

- Switch ON the power supply to the equipment by turn the control key to ON position and release the emergency button.

- Turn the remote key of OFF position.

- Close the rectangular blender lid with the help of the bolts.

- Ensure the pneumatic butterfly valve is closed.

- NOTE:

- The machine will not operate without safety guards railing in position

- For smaller and finer movements use inch button for rotation.

- Charging of materials in to the blender:

- Bring the materials containing IPC bin nearer to the octagonal blender and keep the bin below the discharge butterfly valve.

- Lift the IPC with help of hydraulic lifter and clamp the IPC to the blender discharge valve with help of TC clamp.

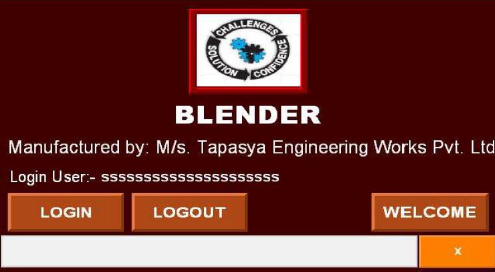

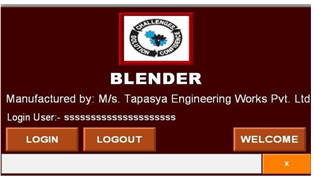

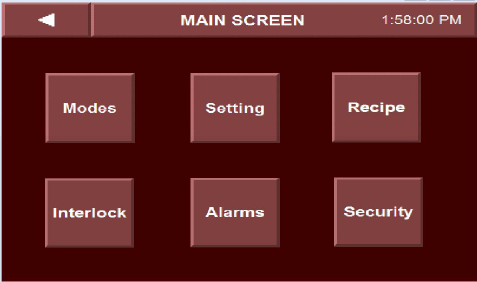

- After power up the following screen will be displayed in the HMI.

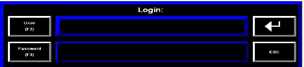

- Touch log in icon and enter user id and password in the following screen then press enter button.

- Now touch ‘Welcome’ icon in the main screen then the following screen will be displayed in the HMI.

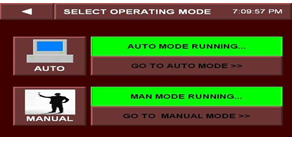

- Touch modes icon in the above screen then the following screen will be displayed.

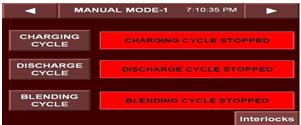

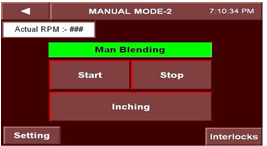

- Touch MANUAL icon in the above screen then “Man Mode Running’ will be indicated with green indication, now touch Go To Manual Mode’ icon in the above screen then the following screen will be displayed

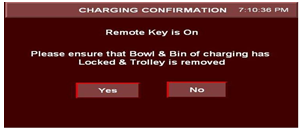

- Touch ‘Charging Cycle’ Icon in the above screen then touch right arrow key then the following screen will popup.

- Ensure that the bin is locked and trolley is removed from the blending area.

- Now press ‘Yes’ Button then blender will move toward up and discharge valve will be opened automatically to discharge the materials from Bin to blender. After prerequisite time the blender will come down.

- Remove the empty bin from the blender by de-clamp the clamp.

- Now fix the new Bin containing materials to the blender and clamp with TC clamp.

- Now press ‘Yes’ then the blender will move upward and discharge valve will opened to discharge the materials from bin to blender. After completion of set time the blender will come down.

- Repeat the above to load all required materials in to the blender.

- After completion of loading of materials press ‘NO’ icon in the above screen, then manual mode – 1 screen will be displayed.

- Touch ‘Blending cycle’ icon and the press right arrow button the following screen will be displayed

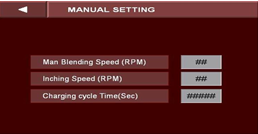

- Touch ‘Setting’ icon in the above screen the following screen will be displayed

- Set the Blender speed, inching speed and charging cycle time (Sec) in manual mode.

- Touch inching icon in the Manual Mode-2 screen and check for proper rotation of blender without any abnormalities.

- Touch ‘interlock’ icon in the above screen then the following screen will be displayed.

- Check for interlocks in red indication and acknowledge alarm & silence the hooter by pressing ‘ACK’ button.

- During Blender operation if you face any interlock then following alarm banner will be pop-up.

- Touch close alarm banner to close the alarm banner.

- Touch left arrow key in the interlock screen and go to blender mode screen.

- OPERATION -BLENDING:

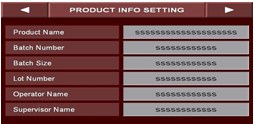

- Touch setting icon in the above screen for setting of blending time and blender speed.

- The following screen will be displayed.

- The following parameters can be entered in this screen.

- Product Name : Enter the product name in this column.

- Batch No : Enter the batch number in this column.

- Batch Size : Enter batch size in Kgs in this column.

- Operator Name : operator name to be entered in this column.

- Supervisor Name: Name of the supervisor to be entered in this column.

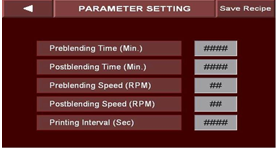

- Touch right arrow icon in the above screen then the following screen will be displayed

- The following parameters can be entered in this screen.

- Preblending Time (Min): Enter the pre blending time in this column.

- Post blending time (Min): Enter the post blending time in this column.

- Preblending speed (RPM): Enter the blender speed during pre blending.

- Post blending speed (RPM): Enter the blender speed during post blend cycle.

- Print Interval: Set the print interval in sec in this column.

- After entering all above parameters, press ‘Save Recipe’ Icon to save the recipe.

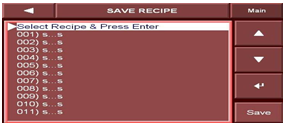

- The following screen will be displayed for recipe save.

- Save the recipe by touching up/down arrow keys and followed by pressing enter key. The message “Recipe Saved Successfully” will be displayed.

- To go back to main screen touch left arrow key.

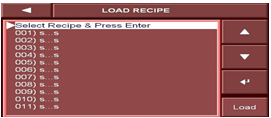

- Touch RECIPE icon in the main screen then the following screen will be displayed.

- Load the required recipe for blending operation by using up/down arrow and then press Load icon. A message ‘Recipe successfully loaded’ icon will be pop.

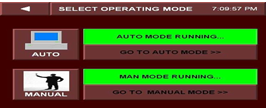

- Touch MODES icon in the main screen then the following screen will be displayed

- Touch ‘AUTO’ Mode icon then Auto Mode Running icon will be indicated with green colour.

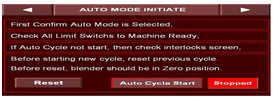

- Now touch ‘go To Auto mode’ icon in the above screen the following screen will be displayed

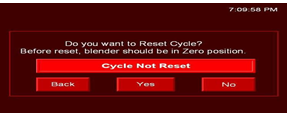

- Check all precautions mentioned in the above screen and then reset the previous cycle by pressing Reset Icon.

- Then the following screen will be displayed, press Yes icon then previous cycle will reset and Cycle reset successfully icon will glows

- Before start Auto cycle user must have to reset the Auto cycle

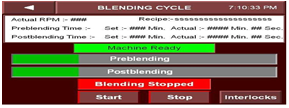

- After resetted the Auto cycle press Auto Cycle Start button, then the following screen will be displayed

- Check the blending time and RPM in the above screen before starting the blending cycle.

- Now press the Start button then pre blending cycle will start and run as per the set parameter.

- Pre blending & Post blending set time and actual time is shown on this screen.

- When Preblending Cycle is completed above screen will be automatically popup.

- Press OK button then blending cycle screen will be displayed, now touch Start icon then post blending cycle will be started with status bar.

- After completion of Post Blending cycle below screen will be automatically popup.

- To go to the Main menu press Main button.

- Touch ALARM icon in the main screen then the alarm screen will be displayed

- Touch Clear History Icon to clear the alarm history.

- UNLOADING OF LUBRICATED BLEND:

- Put the remote selector switch to ON position.

- Open the safety railing and bring the cleaned IPC bin nearer to the blender

- Place the prelabelled IPC below the discharge butterfly valve; connect the power sensor to the IPC.

- Close the safety railing of the blender.

- Open the butterfly valve, by pressing ‘Discharge open’ push button on panel frame, Press ‘Discharge close’ button to close the discharge valve.

- Empty the contents of the blender into the IPC Bin, if the IPC full with powder then discharge will closes automatically.Remove the powder sensor from the IPC.

- Open the safety railing of the machine and remove the IPC. Weigh the IPC along with content and record the weighing details in the product label and In the BMR.

- Repeat the above process until all the lubricated blend is unloaded in to the IPC.

- Transfer the IPC bins to the Hold area for proceeding of further step.

- Record the operation details s in the equipment logbook.

- NOTE: Check that the mains are switched off after completion of blending operation.

- Remove the “UNDER PROCESS” label and affix the “TO BE CLEANED” label to the machine.

- PRECAUTION:

- Check that no person is inside the safety railing and that there is no obstruction to the rotating blender

- Check that all the materials to be mixed are loaded in the blender as per BMR before starting the operation.

- Ensure that the total content of blender is unloaded in to the IPC after blending.

- REFERENCES:

- Not Applicable

- ANNEXURES:

- Not Applicable

- ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Production

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| SS | : | Stainless steel |

| BMR | : | Batch manufacturing record |

| BPR | : | Batch packing record |

| SOP | : | Standard Operating Procedure |

- REVISION HISTORY:

- CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |